Rayon spinning involves creating fibers from regenerated cellulose, offering a smoother texture and higher luster compared to cotton spinning, which uses natural cotton fibers known for their breathability and durability. Rayon fibers provide excellent drape and moisture absorbency, making them ideal for lightweight and soft fabrics, while cotton fibers excel in strength, comfort, and ease of dyeing. The choice between rayon and cotton spinning depends on the desired fabric properties, aesthetics, and end-use applications.

Table of Comparison

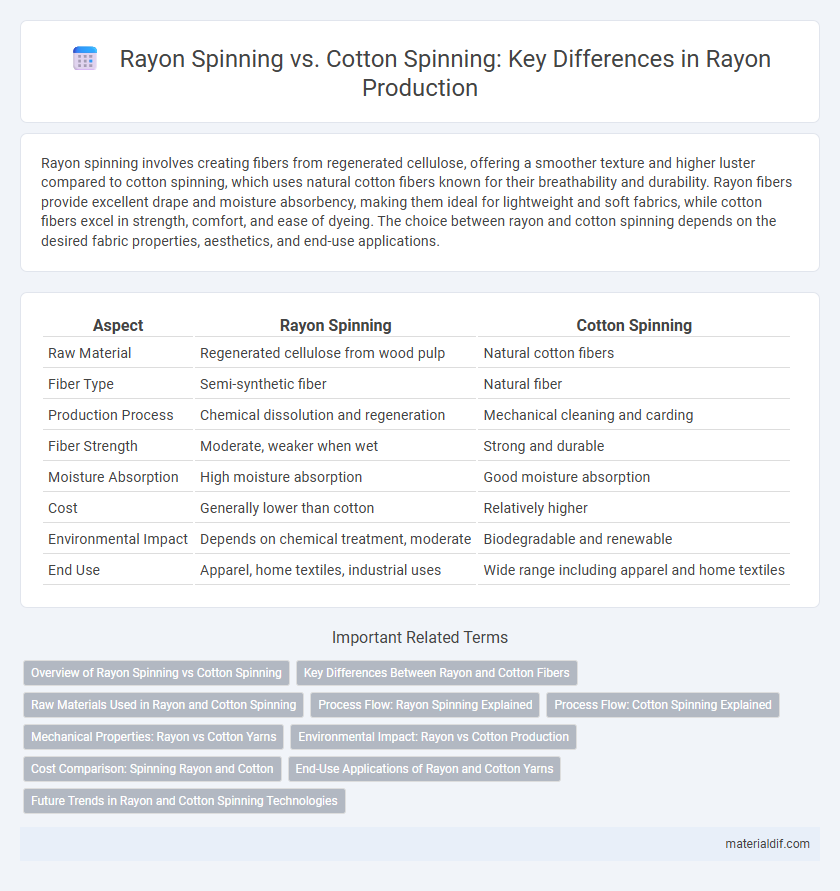

| Aspect | Rayon Spinning | Cotton Spinning |

|---|---|---|

| Raw Material | Regenerated cellulose from wood pulp | Natural cotton fibers |

| Fiber Type | Semi-synthetic fiber | Natural fiber |

| Production Process | Chemical dissolution and regeneration | Mechanical cleaning and carding |

| Fiber Strength | Moderate, weaker when wet | Strong and durable |

| Moisture Absorption | High moisture absorption | Good moisture absorption |

| Cost | Generally lower than cotton | Relatively higher |

| Environmental Impact | Depends on chemical treatment, moderate | Biodegradable and renewable |

| End Use | Apparel, home textiles, industrial uses | Wide range including apparel and home textiles |

Overview of Rayon Spinning vs Cotton Spinning

Rayon spinning involves transforming regenerated cellulose fibers derived from wood pulp into yarns that offer a silk-like texture and high moisture absorption, whereas cotton spinning uses natural cotton fibers known for their durability and breathability. Rayon fibers tend to be smoother and more uniform, resulting in finer yarns, while cotton fibers vary in length and coarseness, affecting yarn strength and texture. The spinning processes differ significantly, with rayon requiring chemical treatment and wet spinning methods, whereas cotton typically undergoes ring or open-end spinning techniques.

Key Differences Between Rayon and Cotton Fibers

Rayon spinning involves the processing of regenerated cellulose fibers derived from wood pulp, resulting in filaments that mimic the softness and drape of natural fibers, whereas cotton spinning uses natural fibers harvested directly from cotton plants. Rayon fibers are more absorbent and have a smoother texture but are less durable and prone to shrinking compared to the stronger, more breathable, and wrinkle-resistant cotton fibers. The differences in their molecular structure influence their performance in textile applications, with rayon offering enhanced sheen and flexibility while cotton provides superior strength and moisture management.

Raw Materials Used in Rayon and Cotton Spinning

Rayon spinning utilizes cellulose derived primarily from wood pulp, bamboo, or cotton linters as its raw material, offering a semi-synthetic fiber option that mimics the properties of natural fibers. Cotton spinning relies exclusively on cotton fibers harvested directly from cotton plants, emphasizing natural fiber processing. The choice of raw materials directly impacts the texture, strength, and environmental footprint of the resulting yarns in both spinning processes.

Process Flow: Rayon Spinning Explained

Rayon spinning involves dissolving cellulose in a chemical solution to create a viscous liquid, which is then extruded through spinnerets to form continuous filaments, unlike cotton spinning that processes natural fibers by carding, combing, and drawing. The rayon process includes steps such as cellulose purification, xanthation, spinning, and washing, allowing for uniform filament production with smooth texture and high tensile strength. This chemical-intensive method enables better control over fiber properties compared to the mechanical nature of cotton spinning, resulting in versatile fabric applications.

Process Flow: Cotton Spinning Explained

Cotton spinning involves ginning, carding, drawing, roving, and ring spinning to transform raw cotton fibers into yarn, emphasizing fiber alignment and strength. Rayon spinning starts with chemically processed cellulose dissolved into a viscous solution, which is extruded through spinnerets to form filaments before twisting into yarn. The cotton spinning process prioritizes mechanical fiber separation and alignment, while rayon spinning hinges on chemical regeneration and filament formation.

Mechanical Properties: Rayon vs Cotton Yarns

Rayon yarns exhibit higher tensile strength and uniformity compared to cotton yarns, making them more suitable for fine textile applications. The elongation at break for rayon is generally greater, providing improved elasticity and resilience under mechanical stress. Cotton yarns, however, offer better moisture absorption and breathability, which are critical for comfort in wearable fabrics.

Environmental Impact: Rayon vs Cotton Production

Rayon spinning involves chemically processing cellulose from wood pulp, resulting in significant water and chemical use, which can lead to environmental pollution if not managed properly. Cotton spinning requires intensive water consumption and pesticide application during cultivation, contributing to soil degradation and water scarcity. Compared to cotton, rayon can offer a more sustainable alternative if sourced from responsibly managed forests and produced using closed-loop processing techniques that minimize harmful emissions and waste.

Cost Comparison: Spinning Rayon and Cotton

Rayon spinning typically incurs higher production costs than cotton spinning due to the complex chemical processes involved in converting cellulose into fiber, which requires specialized equipment and chemicals like carbon disulfide and sodium hydroxide. Cotton spinning benefits from more straightforward mechanical processes and lower raw material expenses, given the natural availability and minimal preprocessing of cotton fibers. Despite the higher initial costs, rayon spinning can achieve competitive pricing through scalable manufacturing and the use of cheaper raw materials such as wood pulp or bamboo.

End-Use Applications of Rayon and Cotton Yarns

Rayon spinning produces yarns that are highly versatile, often used in apparel such as dresses, blouses, and linings due to their smooth texture and excellent moisture absorption. Cotton spinning yields yarns primarily favored for casual wear, home textiles, and denim, benefiting from cotton's natural breathability and durability. Both yarn types serve unique end-use applications that reflect their intrinsic fiber properties and fabric performance characteristics.

Future Trends in Rayon and Cotton Spinning Technologies

Rayon spinning technologies are advancing with sustainable production methods and enhanced fiber blending capabilities to meet rising eco-conscious consumer demands. Cotton spinning is also evolving through automation and precision machinery, improving fiber quality and yield efficiency in response to global supply chain challenges. Future trends emphasize integrating smart manufacturing systems and bio-based chemical processes to optimize both rayon and cotton spinning industries.

Rayon Spinning vs Cotton Spinning Infographic

materialdif.com

materialdif.com