Rayon fabric offers excellent drapability, allowing garments to flow smoothly and conform to body shapes for a flattering silhouette. However, its softness and fluidity result in less structure compared to stiffer fabrics, making it ideal for dresses, blouses, and scarves where movement and comfort are prioritized. Choosing rayon balances a relaxed fit with elegance, though it may require careful layering or support to maintain shape in tailored designs.

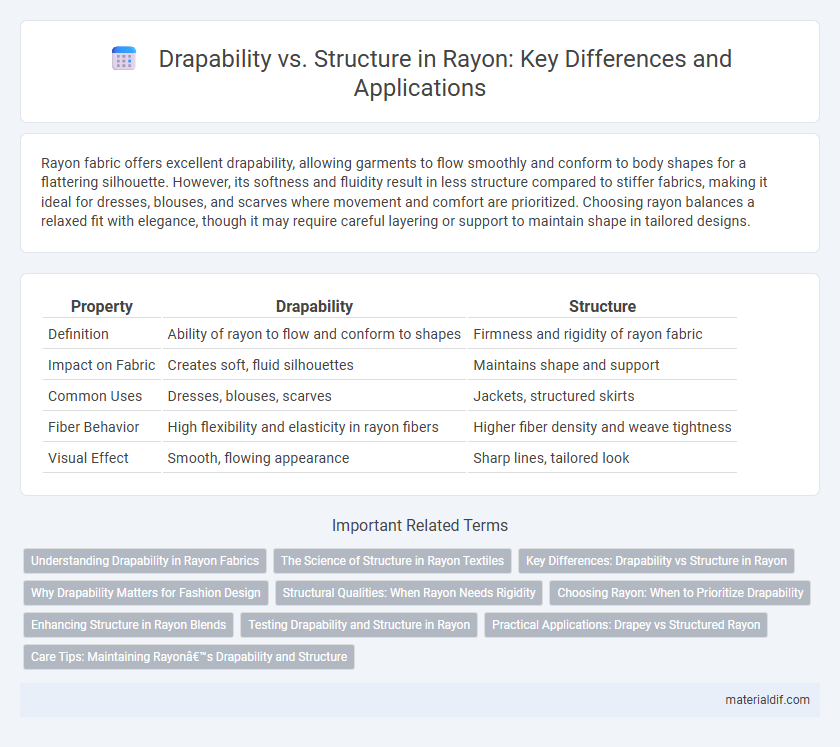

Table of Comparison

| Property | Drapability | Structure |

|---|---|---|

| Definition | Ability of rayon to flow and conform to shapes | Firmness and rigidity of rayon fabric |

| Impact on Fabric | Creates soft, fluid silhouettes | Maintains shape and support |

| Common Uses | Dresses, blouses, scarves | Jackets, structured skirts |

| Fiber Behavior | High flexibility and elasticity in rayon fibers | Higher fiber density and weave tightness |

| Visual Effect | Smooth, flowing appearance | Sharp lines, tailored look |

Understanding Drapability in Rayon Fabrics

Drapability in rayon fabrics refers to the material's ability to flow and conform smoothly over surfaces, influenced by fiber length, weave, and fabric weight. Rayon's semi-synthetic cellulose fibers provide excellent draping qualities, making it a preferred choice for garments requiring fluid movement and soft folds. Balancing drapability with structure involves selecting appropriate blends and treatments to enhance stability without compromising the fabric's natural flow.

The Science of Structure in Rayon Textiles

Rayon textiles exhibit a unique balance between drapability and structure due to the fiber's semicrystalline molecular arrangement, which influences flexibility and tensile strength. The hydrogen bonding within cellulose chains in rayon enhances fabric structure, while maintaining a soft hand that allows fluid draping. Understanding the crystalline-amorphous regions helps in engineering rayon fabrics with tailored mechanical properties for specific textile applications.

Key Differences: Drapability vs Structure in Rayon

Rayon exhibits high drapability, allowing it to flow smoothly and conform to body contours, making it ideal for garments requiring fluid movement. In contrast, its structure is relatively weaker compared to natural fibers like cotton or wool, resulting in less rigidity and durability. The key difference lies in rayon's soft, silk-like texture that enhances drapability, whereas its low tensile strength limits structural firmness in tailored applications.

Why Drapability Matters for Fashion Design

Drapability influences how rayon fabric contours to the body, enhancing garment fit and comfort while allowing designers to create fluid, dynamic silhouettes. Its ability to flow smoothly affects the visual appeal and movement of clothing, making it essential for fashion pieces that prioritize elegance and wearability. Understanding rayon's drapability helps designers balance aesthetic appeal with functional structure in apparel creation.

Structural Qualities: When Rayon Needs Rigidity

Rayon exhibits excellent drapability due to its smooth, flexible fibers but often lacks inherent rigidity essential for structured garments. Enhancing rayon with blending fibers like polyester or incorporating mechanical treatments such as heat-setting can improve its structural qualities without sacrificing comfort. These modifications enable rayon to maintain shape and crispness, making it suitable for tailored clothing and upholstery requiring firmness alongside fluidity.

Choosing Rayon: When to Prioritize Drapability

Choosing rayon for garments that require fluidity and softness enhances drapability, making it ideal for dresses, blouses, and flowing skirts. The fabric's ability to conform smoothly to the body emphasizes curves without stiffness, which suits designs emphasizing elegance and movement. Prioritize rayon when comfort and a graceful silhouette are essential, rather than rigid structure or formality.

Enhancing Structure in Rayon Blends

Rayon blends enhance fabric structure by combining rayon's softness with the stability of fibers like polyester or nylon, resulting in improved drapability without sacrificing durability. The integration of synthetic fibers increases wrinkle resistance and fabric resilience, allowing garments to maintain shape and form during wear. This balance between drapability and enhanced structure in rayon blends makes them ideal for tailored clothing and versatile fashion applications.

Testing Drapability and Structure in Rayon

Testing drapability in rayon involves measuring the fabric's ability to conform smoothly over surfaces, assessed using methods like the drape coefficient test, which quantifies the fabric's flexibility and fluidity. Structure in rayon is evaluated by analyzing fiber alignment, weave tightness, and tensile strength through standardized tests such as the fabric stiffness test and elongation measurements, determining its durability and dimensional stability. Accurate assessment of both drapability and structure is essential for optimizing rayon's performance in apparel and interior textiles, ensuring a balance between aesthetic flow and material integrity.

Practical Applications: Drapey vs Structured Rayon

Drapey rayon excels in fashion applications requiring fluidity, such as flowing dresses and scarves, due to its soft texture and flexibility. Structured rayon is ideal for tailored garments like blazers and skirts, offering shape retention and durability. Designers select rayon types based on desired garment silhouette and functionality, balancing comfort with aesthetic appeal.

Care Tips: Maintaining Rayon’s Drapability and Structure

Maintaining rayon's drapability and structure requires careful laundering by using cold water and gentle cycles to prevent fabric distortion. Air drying on flat surfaces preserves rayon's smooth drape and prevents shrinkage or loss of shape. Avoiding high heat and harsh chemicals extends the fabric's softness and structural integrity for long-lasting wear.

Drapability vs Structure Infographic

materialdif.com

materialdif.com