Cupro rayon, derived from cotton linter, offers a silky texture and excellent breathability, making it ideal for luxurious, lightweight garments. Tencel rayon, produced from sustainably sourced wood pulp via a closed-loop process, emphasizes eco-friendliness and moisture-wicking properties, perfect for activewear and sensitive skin. Both fibers provide softness and durability, but Tencel stands out for its environmental benefits while Cupro excels in a silky feel.

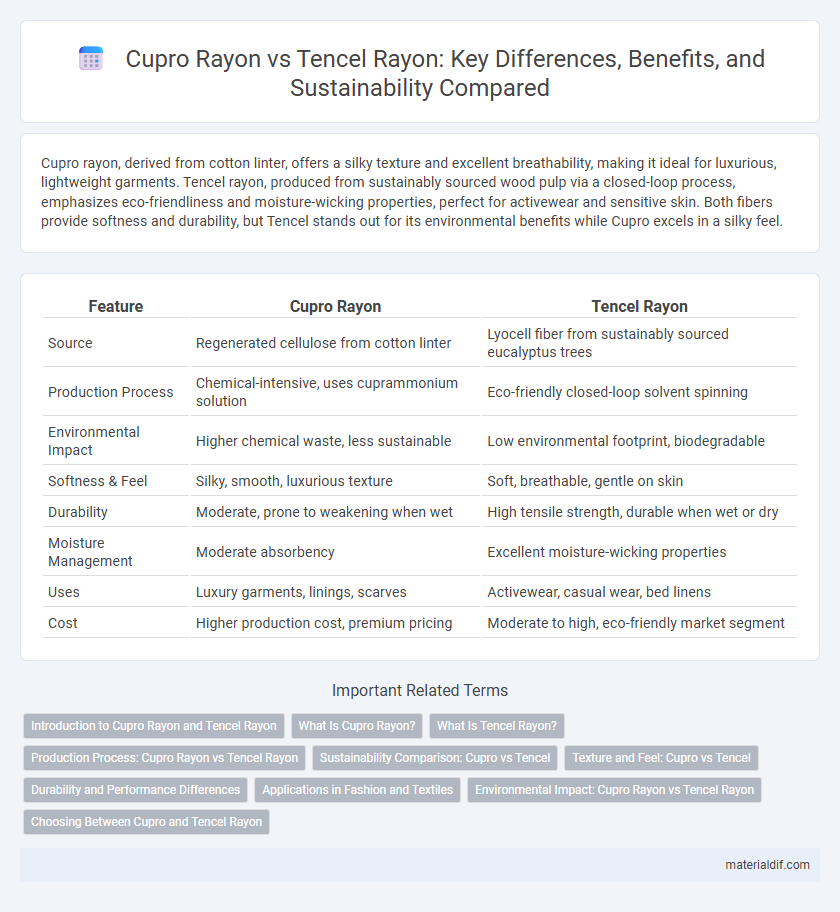

Table of Comparison

| Feature | Cupro Rayon | Tencel Rayon |

|---|---|---|

| Source | Regenerated cellulose from cotton linter | Lyocell fiber from sustainably sourced eucalyptus trees |

| Production Process | Chemical-intensive, uses cuprammonium solution | Eco-friendly closed-loop solvent spinning |

| Environmental Impact | Higher chemical waste, less sustainable | Low environmental footprint, biodegradable |

| Softness & Feel | Silky, smooth, luxurious texture | Soft, breathable, gentle on skin |

| Durability | Moderate, prone to weakening when wet | High tensile strength, durable when wet or dry |

| Moisture Management | Moderate absorbency | Excellent moisture-wicking properties |

| Uses | Luxury garments, linings, scarves | Activewear, casual wear, bed linens |

| Cost | Higher production cost, premium pricing | Moderate to high, eco-friendly market segment |

Introduction to Cupro Rayon and Tencel Rayon

Cupro rayon is a regenerated cellulose fiber derived from cotton linter, known for its silky texture, breathability, and biodegradability, making it popular in luxury garments and linings. Tencel rayon, branded lyocell, is produced from sustainably sourced eucalyptus wood pulp using a closed-loop process, offering exceptional moisture-wicking properties, strength, and eco-friendly attributes. Both fibers serve as sustainable alternatives to traditional rayon, with Cupro emphasizing softness and luster, while Tencel prioritizes durability and environmental impact.

What Is Cupro Rayon?

Cupro rayon is a regenerated cellulose fiber made from cotton linter, a byproduct of cotton production, known for its silk-like texture and breathability. Compared to Tencel rayon, which is derived from sustainably harvested wood pulp using a closed-loop process, Cupro offers exceptional softness and moisture-wicking properties but has a slightly less eco-friendly production method. Its smooth, lightweight fabric is often used in luxury apparel and linings due to its hypoallergenic qualities and elegant drape.

What Is Tencel Rayon?

Tencel rayon is a type of lyocell fiber made from sustainably sourced wood pulp, known for its softness, breathability, and eco-friendly production process involving a closed-loop system that recycles water and solvents. Compared to cupro rayon, which is made from cotton linter and involves more chemical processing, Tencel rayon offers superior moisture management and durability. Its natural origin and environmentally responsible manufacturing make Tencel a preferred choice in sustainable fashion and textiles.

Production Process: Cupro Rayon vs Tencel Rayon

Cupro rayon is produced using a chemical-intensive process that dissolves cotton linter in cuprammonium solution, followed by regeneration into fine fibers, often involving toxic chemicals like copper and ammonia. Tencel rayon, also known as lyocell, utilizes a closed-loop production method where wood pulp is dissolved in a non-toxic organic solvent and almost all chemicals are recovered and reused, minimizing environmental impact. The sustainable and eco-friendly production process of Tencel contrasts sharply with the chemically intensive and less environmentally responsible production method of Cupro rayon.

Sustainability Comparison: Cupro vs Tencel

Cupro rayon is produced from cotton linter, a byproduct of cotton production, utilizing a chemical-intensive process with limited recycling of solvents, which raises concerns about environmental impact. Tencel rayon, derived from sustainably managed eucalyptus trees, employs a closed-loop production system that recycles water and solvents at a rate exceeding 99%, significantly reducing waste and energy consumption. The sustainable forestry practices and eco-friendly manufacturing of Tencel position it as a more environmentally responsible choice compared to the chemically heavy and less circular Cupro production.

Texture and Feel: Cupro vs Tencel

Cupro rayon features a silky, smooth texture with a soft, breathable feel that drapes elegantly, often compared to luxurious satin. Tencel rayon offers a slightly more matte finish with a crisp, cool touch, providing excellent moisture-wicking qualities and a gentle feel against the skin. Both fibers enhance comfort but differ in tactile experience, with Cupro emphasizing silkiness and Tencel prioritizing breathability and durability.

Durability and Performance Differences

Cupro rayon exhibits moderate durability with a smooth, silk-like texture suitable for luxury garments, but it tends to be less resistant to abrasion and moisture compared to Tencel rayon. Tencel rayon, derived from sustainably sourced wood pulp, offers superior tensile strength, excellent moisture-wicking properties, and enhanced resistance to wrinkles and shrinking. Tencel's performance makes it a preferred choice for activewear and everyday clothing requiring long-lasting durability and comfort.

Applications in Fashion and Textiles

Cupro rayon, known for its silk-like feel and breathable properties, is widely used in high-end fashion for linings, blouses, and dresses that require a smooth, luxurious finish. Tencel rayon, derived from sustainably sourced wood pulp, excels in activewear and casual clothing due to its moisture-wicking abilities, durability, and eco-friendly appeal. Both fibers cater to different niches within the fashion and textile industry, with Cupro favored for elegance and Tencel preferred for sustainability and performance wear.

Environmental Impact: Cupro Rayon vs Tencel Rayon

Cupro rayon, derived from cotton linter, involves a chemical-intensive production process with issues in solvent recovery, leading to higher environmental concerns compared to Tencel rayon. Tencel rayon, produced from sustainably sourced eucalyptus wood pulp through the closed-loop lyocell process, boasts minimal chemical waste and superior biodegradability. The sustainable manufacturing and lower water consumption make Tencel a more eco-friendly alternative to Cupro in the textile industry.

Choosing Between Cupro and Tencel Rayon

Choosing between Cupro and Tencel rayon depends on the desired fabric properties and environmental considerations. Cupro rayon offers a silky texture and excellent breathability, making it ideal for luxury clothing, while Tencel rayon is renowned for its sustainability, softness, and moisture-wicking capabilities, often preferred in eco-friendly fashion. Understanding the specific application and sustainability goals helps determine the best choice between these two innovative rayon fibers.

Cupro rayon vs Tencel rayon Infographic

materialdif.com

materialdif.com