Spun-dyed Rayon offers superior colorfastness and vibrant hues by integrating color during the fiber formation process, resulting in fabrics with consistent and long-lasting shades. Piece-dyed Rayon, on the other hand, is dyed after fabric production, which can lead to less uniform coloration and potential fading over time. Choosing spun-dyed Rayon enhances durability and color retention, making it ideal for high-quality textile applications.

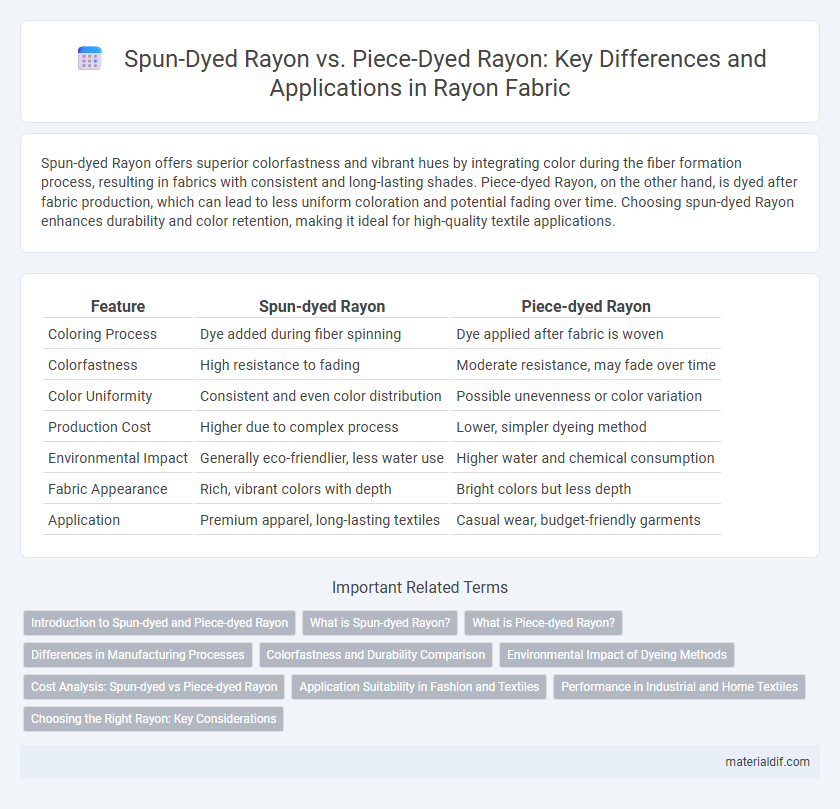

Table of Comparison

| Feature | Spun-dyed Rayon | Piece-dyed Rayon |

|---|---|---|

| Coloring Process | Dye added during fiber spinning | Dye applied after fabric is woven |

| Colorfastness | High resistance to fading | Moderate resistance, may fade over time |

| Color Uniformity | Consistent and even color distribution | Possible unevenness or color variation |

| Production Cost | Higher due to complex process | Lower, simpler dyeing method |

| Environmental Impact | Generally eco-friendlier, less water use | Higher water and chemical consumption |

| Fabric Appearance | Rich, vibrant colors with depth | Bright colors but less depth |

| Application | Premium apparel, long-lasting textiles | Casual wear, budget-friendly garments |

Introduction to Spun-dyed and Piece-dyed Rayon

Spun-dyed rayon involves dyeing the fibers before they are spun into yarn, resulting in vibrant colors with enhanced colorfastness and uniformity. Piece-dyed rayon refers to the process where the fabric is dyed after weaving, allowing for a wider range of color options but sometimes with less durability in color retention. Both techniques impact the texture, appearance, and performance of the final textile, with spun-dyed offering superior resistance to fading compared to piece-dyed rayon.

What is Spun-dyed Rayon?

Spun-dyed rayon is a type of fiber where the dye is applied to the viscose solution before the fiber is formed, resulting in color embedded within the filament itself. This process ensures superior colorfastness and resistance to fading compared to piece-dyed rayon, which is dyed after the fabric is woven. The deep integration of dye in spun-dyed rayon enhances durability and maintains vibrant hues through multiple washes.

What is Piece-dyed Rayon?

Piece-dyed rayon refers to fabric that is dyed after the weaving or knitting process, allowing for consistent color absorption and uniformity across the entire textile. This method enhances colorfastness and provides designers with flexibility in selecting colors post-production, making it ideal for custom and limited batch orders. Compared to spun-dyed rayon, piece-dyed rayon offers a broader range of vibrant hues while maintaining the soft, breathable qualities inherent to rayon fibers.

Differences in Manufacturing Processes

Spun-dyed rayon involves adding color pigments directly to the viscose solution before fiber extrusion, resulting in deeply integrated, long-lasting coloration and uniform dye penetration throughout the fiber. Piece-dyed rayon undergoes dyeing after the fabric is woven, where the undyed fabric is immersed in dye baths, leading to surface-level color absorption that can fade more quickly. The manufacturing distinction impacts durability, color fastness, and environmental emissions associated with dyeing processes.

Colorfastness and Durability Comparison

Spun-dyed rayon, also known as dope-dyed rayon, incorporates color into the fiber during the spinning process, resulting in superior colorfastness and resistance to fading compared to piece-dyed rayon, which is colored after fabric production. The dye penetration in spun-dyed rayon enhances durability, maintaining vibrant hues even after repeated washing and exposure to sunlight. In contrast, piece-dyed rayon often experiences quicker color loss and weaker fiber integrity due to surface-level dye application, leading to reduced longevity in textile performance.

Environmental Impact of Dyeing Methods

Spun-dyed rayon involves integrating color pigments directly into the fiber during the spinning process, significantly reducing water consumption and chemical waste compared to piece-dyed rayon, which requires post-weaving dye baths that generate substantial wastewater and require extensive chemical treatments. The closed-loop systems often used in spun-dye technology enable better recovery and reuse of dyes and solvents, minimizing environmental pollution and lowering carbon footprints. In contrast, piece-dyeing's reliance on large volumes of water and energy-intensive drying processes contributes to higher environmental impact and challenges in managing effluents sustainably.

Cost Analysis: Spun-dyed vs Piece-dyed Rayon

Spun-dyed rayon involves dyeing fibers before the spinning process, resulting in higher upfront costs due to complex manufacturing but offering long-term savings through colorfastness and reduced waste. Piece-dyed rayon, dyed after fabric production, is generally cheaper initially but can incur additional expenses from color fading, frequent re-dyeing, and lower durability. Overall, spun-dyed rayon provides better cost efficiency over time despite higher initial investment compared to piece-dyed rayon.

Application Suitability in Fashion and Textiles

Spun-dyed rayon offers superior colorfastness and uniformity, making it ideal for high-end fashion applications where vibrant, long-lasting hues are essential. Piece-dyed rayon provides versatility and cost-effectiveness, suitable for mass-produced textiles requiring varied color options with moderate durability. Designers often prefer spun-dyed rayon for premium garments, while piece-dyed rayon is favored in casual wear and home textiles.

Performance in Industrial and Home Textiles

Spun-dyed rayon fibers exhibit superior colorfastness and resistance to fading compared to piece-dyed rayon, making them ideal for industrial textiles exposed to harsh environments. Their inherent coloration ensures uniform dye penetration, enhancing durability for applications such as upholstery and drapery in both commercial and home settings. Piece-dyed rayon offers versatility in color customization but may demonstrate lower long-term performance due to surface-level dyeing prone to wear and washing degradation.

Choosing the Right Rayon: Key Considerations

Spun-dyed rayon offers vibrant, long-lasting colors by integrating dye at the fiber manufacturing stage, enhancing colorfastness and reducing fading compared to piece-dyed rayon. Piece-dyed rayon undergoes dyeing after the fabric is woven, allowing for more flexibility in color choices but often resulting in less durable color retention. When choosing the right rayon, consider factors like desired color durability, production methods, and end-use applications to ensure optimal performance and aesthetic appeal.

Spun-dyed Rayon vs Piece-dyed Rayon Infographic

materialdif.com

materialdif.com