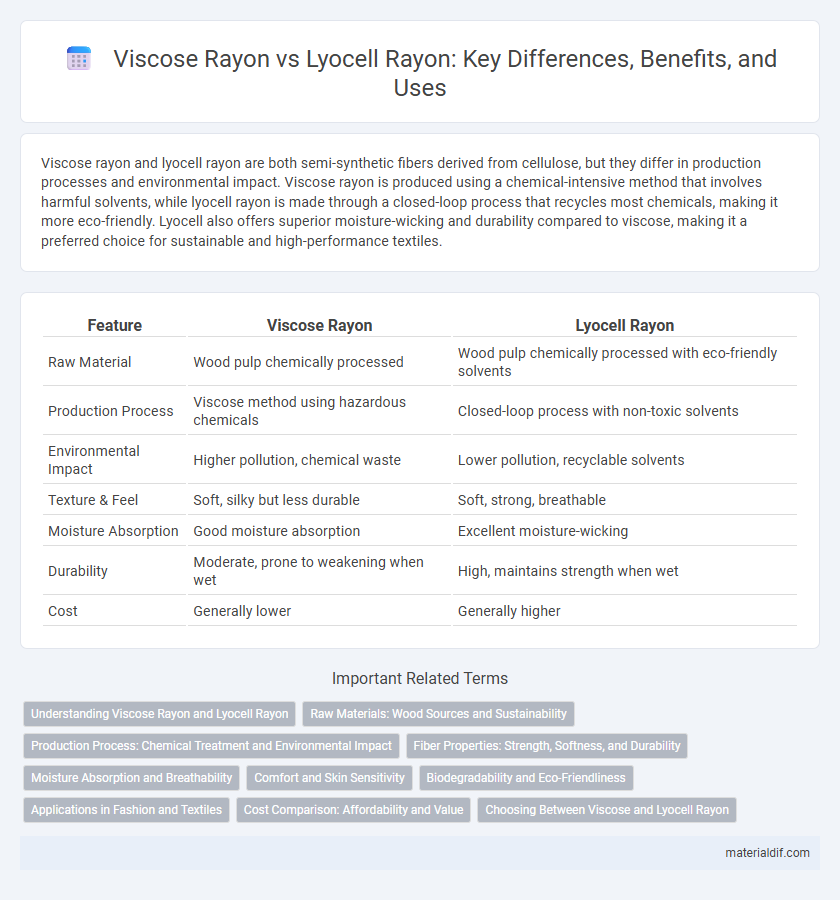

Viscose rayon and lyocell rayon are both semi-synthetic fibers derived from cellulose, but they differ in production processes and environmental impact. Viscose rayon is produced using a chemical-intensive method that involves harmful solvents, while lyocell rayon is made through a closed-loop process that recycles most chemicals, making it more eco-friendly. Lyocell also offers superior moisture-wicking and durability compared to viscose, making it a preferred choice for sustainable and high-performance textiles.

Table of Comparison

| Feature | Viscose Rayon | Lyocell Rayon |

|---|---|---|

| Raw Material | Wood pulp chemically processed | Wood pulp chemically processed with eco-friendly solvents |

| Production Process | Viscose method using hazardous chemicals | Closed-loop process with non-toxic solvents |

| Environmental Impact | Higher pollution, chemical waste | Lower pollution, recyclable solvents |

| Texture & Feel | Soft, silky but less durable | Soft, strong, breathable |

| Moisture Absorption | Good moisture absorption | Excellent moisture-wicking |

| Durability | Moderate, prone to weakening when wet | High, maintains strength when wet |

| Cost | Generally lower | Generally higher |

Understanding Viscose Rayon and Lyocell Rayon

Viscose rayon, derived from chemically treated cellulose fibers, offers a silky texture and high absorbency but involves intensive chemical processing. Lyocell rayon, produced through a closed-loop solvent spinning process, is more environmentally friendly and provides superior strength and moisture-wicking properties. Understanding the differences helps in choosing the right fiber for sustainable fashion and textile applications.

Raw Materials: Wood Sources and Sustainability

Viscose rayon is primarily derived from cellulose extracted from hardwoods like beech, eucalyptus, and pine, often using chemical-intensive processes that raise environmental concerns. Lyocell rayon, in contrast, typically utilizes sustainably sourced eucalyptus wood and employs a closed-loop solvent spinning method that recycles up to 99% of chemicals, significantly reducing ecological impact. The sustainable forestry management and efficient production techniques of lyocell rayon position it as an eco-friendlier alternative to traditional viscose rayon.

Production Process: Chemical Treatment and Environmental Impact

Viscose rayon production involves chemical treatment with carbon disulfide and sodium hydroxide, generating toxic by-products that pose environmental hazards and health risks. Lyocell rayon uses a closed-loop process with non-toxic N-methylmorpholine N-oxide solvent, allowing for solvent recovery and minimal waste, significantly reducing environmental impact. The sustainable production of lyocell results in lower water and energy consumption compared to the more pollutive viscose method.

Fiber Properties: Strength, Softness, and Durability

Viscose rayon fibers exhibit moderate strength and softness but tend to have lower durability, making them prone to wear and tear over time. Lyocell rayon fibers are known for their superior strength, exceptional softness, and enhanced durability due to a more environmentally friendly production process. The moisture-wicking properties and smooth surface of lyocell contribute to its longer lifespan compared to viscose rayon.

Moisture Absorption and Breathability

Viscose rayon exhibits high moisture absorption due to its cellulose base, making it effective at wicking sweat away from the skin but can retain moisture longer, leading to slower drying times. Lyocell rayon, derived from sustainably processed wood pulp, offers superior breathability with excellent moisture management, rapidly absorbing and releasing moisture to enhance comfort. The advanced fiber structure of lyocell ensures better airflow and quicker drying compared to traditional viscose rayon, making it ideal for activewear and humid conditions.

Comfort and Skin Sensitivity

Viscose rayon offers a soft, smooth texture that enhances comfort but may cause irritation for sensitive skin due to its chemical processing. Lyocell rayon provides superior breathability and moisture-wicking properties, making it ideal for individuals with sensitive or allergy-prone skin. Both fibers are biodegradable, but lyocell's eco-friendly production further reduces risks associated with skin irritation.

Biodegradability and Eco-Friendliness

Viscose rayon, derived from cellulose but processed with toxic chemicals, tends to have lower biodegradability and raises environmental concerns due to chemical waste. Lyocell rayon, produced through a closed-loop process that recycles solvents, offers superior eco-friendliness and faster biodegradability, making it a sustainable alternative. The biodegradable nature of lyocell fiber significantly reduces its ecological footprint compared to viscose.

Applications in Fashion and Textiles

Viscose rayon is widely used in fashion and textiles for its silk-like appearance and breathability, making it ideal for dresses, blouses, and linings. Lyocell rayon is favored for sustainable fashion due to its eco-friendly production and excellent moisture-wicking properties, commonly applied in activewear, casual clothing, and denim blends. Both fibers offer versatility, but lyocell's durability and environmental benefits increasingly drive its adoption in modern textile manufacturing.

Cost Comparison: Affordability and Value

Viscose rayon is generally more affordable than lyocell rayon, making it a popular choice for budget-conscious consumers and large-scale textile production. Lyocell rayon, while more expensive, offers superior durability, moisture-wicking properties, and eco-friendly manufacturing processes, which add value for premium and sustainable apparel markets. The cost difference reflects lyocell's advanced production techniques and environmental benefits, justifying its higher price point despite viscose's wide availability and lower cost.

Choosing Between Viscose and Lyocell Rayon

Viscose rayon, derived from chemically treated wood pulp, offers a soft, breathable fabric with a silky appearance but involves environmentally harmful production processes. Lyocell rayon, produced through a closed-loop system using non-toxic solvents, provides higher durability, better moisture-wicking properties, and enhanced eco-friendliness. Choosing between viscose and lyocell depends on prioritizing sustainability and fabric performance, where lyocell is favored for environmentally conscious consumers and viscose for cost-effective, versatile textile applications.

Viscose Rayon vs Lyocell Rayon Infographic

materialdif.com

materialdif.com