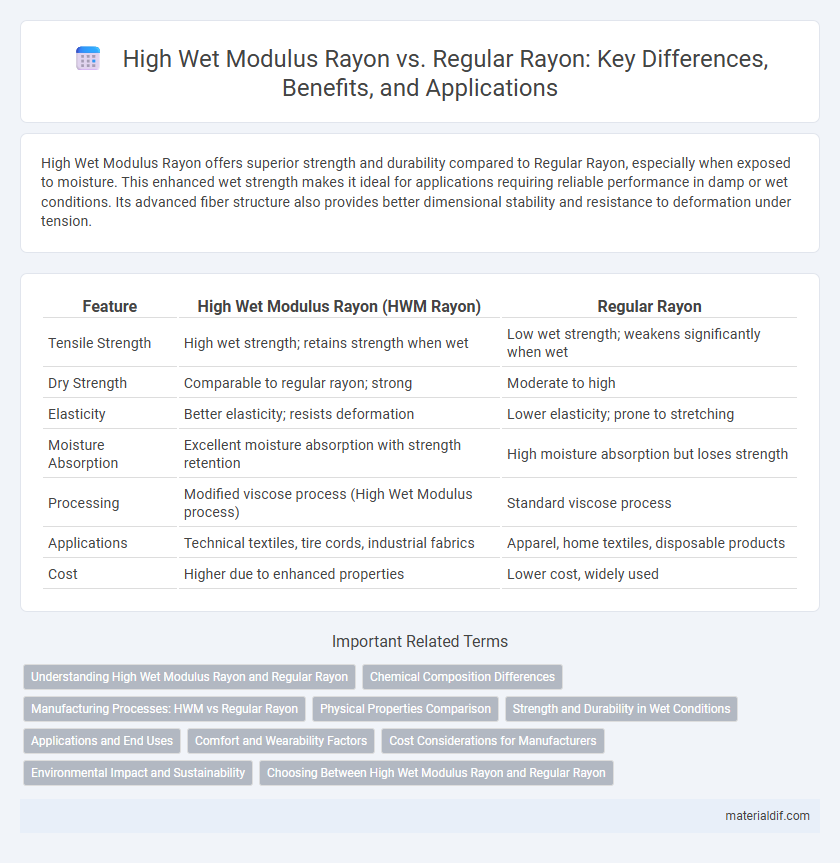

High Wet Modulus Rayon offers superior strength and durability compared to Regular Rayon, especially when exposed to moisture. This enhanced wet strength makes it ideal for applications requiring reliable performance in damp or wet conditions. Its advanced fiber structure also provides better dimensional stability and resistance to deformation under tension.

Table of Comparison

| Feature | High Wet Modulus Rayon (HWM Rayon) | Regular Rayon |

|---|---|---|

| Tensile Strength | High wet strength; retains strength when wet | Low wet strength; weakens significantly when wet |

| Dry Strength | Comparable to regular rayon; strong | Moderate to high |

| Elasticity | Better elasticity; resists deformation | Lower elasticity; prone to stretching |

| Moisture Absorption | Excellent moisture absorption with strength retention | High moisture absorption but loses strength |

| Processing | Modified viscose process (High Wet Modulus process) | Standard viscose process |

| Applications | Technical textiles, tire cords, industrial fabrics | Apparel, home textiles, disposable products |

| Cost | Higher due to enhanced properties | Lower cost, widely used |

Understanding High Wet Modulus Rayon and Regular Rayon

High Wet Modulus Rayon, also known as HWM rayon or polynosic fiber, exhibits superior strength and dimensional stability when wet compared to Regular Rayon, making it ideal for durable textiles and industrial applications. Regular Rayon, derived from cellulose fibers, is softer and more absorbent but tends to lose strength and shape when exposed to moisture. Understanding these differences is crucial for selecting the right type of rayon based on performance requirements in clothing, home textiles, and technical fabrics.

Chemical Composition Differences

High Wet Modulus (HWM) Rayon differs from regular rayon primarily in its chemical composition, where increased cross-linking within cellulose chains enhances fiber strength and stability. HWM rayon undergoes a modified viscose process involving additives like sodium sulfate and carbon disulfide at optimized concentrations, resulting in a higher degree of polymerization and crystallinity. These chemical modifications produce fibers with superior wet strength, dimensional stability, and reduced shrinkage compared to regular rayon, which has a lower molecular orientation and fewer cross-links.

Manufacturing Processes: HWM vs Regular Rayon

High Wet Modulus (HWM) Rayon undergoes a specialized viscose process that includes controlled aging and xanthation steps to increase molecular orientation and crystallinity, resulting in improved wet strength. Regular Rayon manufacturing involves a standard viscose process without these additional modifications, leading to lower tensile strength when wet. The refined processing of HWM Rayon enhances fiber durability and improves performance in textile applications requiring high wet strength.

Physical Properties Comparison

High Wet Modulus (HWM) Rayon exhibits superior tensile strength and dimensional stability compared to regular rayon, making it more durable under wet conditions. The fiber structure of HWM rayon allows for enhanced resistance to shrinkage and stretching when exposed to moisture, resulting in better shape retention. Regular rayon tends to be weaker and more prone to deformation in wet environments, limiting its applications where durability is essential.

Strength and Durability in Wet Conditions

High Wet Modulus (HWM) Rayon exhibits superior strength and durability compared to regular Rayon when exposed to wet conditions due to its enhanced molecular orientation and crystallinity. The increased wet modulus translates to reduced fiber swelling and improved mechanical performance, making HWM Rayon more resistant to deformation and tensile weakening in moisture. These properties enable HWM Rayon to maintain structural integrity and longevity in applications requiring frequent or prolonged exposure to water.

Applications and End Uses

High Wet Modulus Rayon exhibits superior strength and dimensional stability when wet, making it ideal for industrial applications such as tire cords, surgical sutures, and durable apparel textiles. Regular Rayon, with lower wet strength and more shrinkage, is commonly used in fashion fabrics, home textiles, and disposable products where softness and drape are prioritized. The enhanced performance of High Wet Modulus Rayon extends the lifespan and reliability of products subjected to moisture and stress.

Comfort and Wearability Factors

High Wet Modulus (HWM) Rayon offers enhanced strength and durability compared to regular rayon, resulting in improved comfort and wearability for everyday garments. The fiber's smoother texture and higher wet strength reduce fabric shrinkage and maintain shape better during washes, providing a more consistent fit and feel. These attributes make HWM rayon ideal for clothing that demands both softness and long-lasting wear performance.

Cost Considerations for Manufacturers

High Wet Modulus (HWM) Rayon offers manufacturers enhanced strength and durability, resulting in lower defect rates and reduced waste compared to regular rayon, which can translate into cost savings despite its typically higher raw material price. Regular rayon, while cheaper per unit, often incurs higher expenses related to product replacement and quality control due to its weaker wet strength. Manufacturers must balance these factors, considering material costs alongside long-term efficiency and product performance when selecting between HWM and regular rayon.

Environmental Impact and Sustainability

High Wet Modulus (HWM) Rayon requires less chemical processing than regular rayon, resulting in lower emissions of harmful substances like carbon disulfide and sulfuric acid. Its higher fiber strength reduces fabric breakage and waste during manufacturing, contributing to improved material efficiency. HWM Rayon's enhanced durability extends garment lifespan, supporting sustainable consumption by decreasing the frequency of replacement compared to regular rayon products.

Choosing Between High Wet Modulus Rayon and Regular Rayon

High Wet Modulus (HWM) Rayon offers superior strength and dimensional stability when wet, making it ideal for garments requiring durability and shape retention during use and washing. Regular Rayon tends to be softer and more breathable but lacks the enhanced wet strength and resilience of HWM Rayon, which can lead to quicker wear and deformation. Choosing between High Wet Modulus Rayon and Regular Rayon depends on the specific application, balancing strength and longevity against softness and drape.

High Wet Modulus Rayon vs Regular Rayon Infographic

materialdif.com

materialdif.com