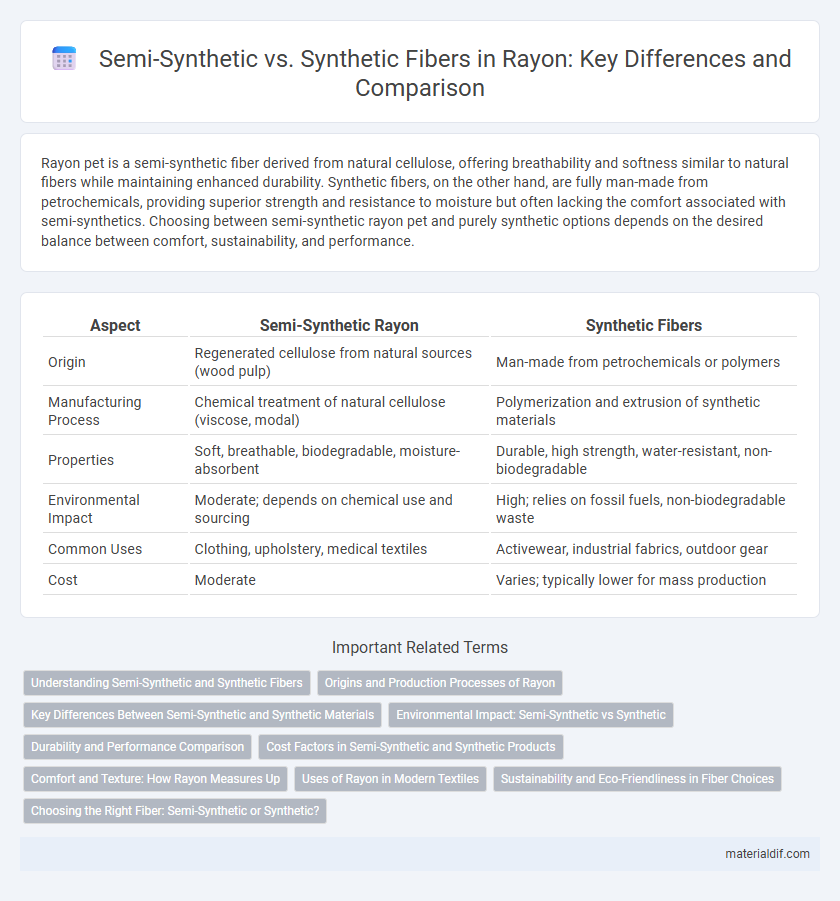

Rayon pet is a semi-synthetic fiber derived from natural cellulose, offering breathability and softness similar to natural fibers while maintaining enhanced durability. Synthetic fibers, on the other hand, are fully man-made from petrochemicals, providing superior strength and resistance to moisture but often lacking the comfort associated with semi-synthetics. Choosing between semi-synthetic rayon pet and purely synthetic options depends on the desired balance between comfort, sustainability, and performance.

Table of Comparison

| Aspect | Semi-Synthetic Rayon | Synthetic Fibers |

|---|---|---|

| Origin | Regenerated cellulose from natural sources (wood pulp) | Man-made from petrochemicals or polymers |

| Manufacturing Process | Chemical treatment of natural cellulose (viscose, modal) | Polymerization and extrusion of synthetic materials |

| Properties | Soft, breathable, biodegradable, moisture-absorbent | Durable, high strength, water-resistant, non-biodegradable |

| Environmental Impact | Moderate; depends on chemical use and sourcing | High; relies on fossil fuels, non-biodegradable waste |

| Common Uses | Clothing, upholstery, medical textiles | Activewear, industrial fabrics, outdoor gear |

| Cost | Moderate | Varies; typically lower for mass production |

Understanding Semi-Synthetic and Synthetic Fibers

Semi-synthetic fibers like rayon are derived from natural cellulose sources such as wood pulp, then chemically processed to create a fiber, blending natural origins with industrial treatment. Synthetic fibers, including polyester and nylon, are entirely man-made from petrochemicals through polymerization, offering consistent strength and durability. Understanding the distinction highlights rayon's unique position as an eco-friendly alternative that combines biodegradability with versatile textile applications.

Origins and Production Processes of Rayon

Rayon is a semi-synthetic fiber derived primarily from natural cellulose sources such as wood pulp or cotton linters, distinguishing it from fully synthetic fibers which are made from petrochemicals. The production of rayon involves chemically dissolving cellulose before regenerating it into fibers through processes like the viscose or lyocell methods. Synthetic fibers, in contrast, undergo polymerization of monomers to create entirely man-made materials such as polyester or nylon.

Key Differences Between Semi-Synthetic and Synthetic Materials

Semi-synthetic materials like rayon are derived from natural polymers such as cellulose, which undergo chemical processing to enhance properties like softness and breathability, while synthetic materials like polyester are fully man-made from petrochemicals, offering higher durability and resistance to moisture. Rayon exhibits better moisture absorption and biodegradability compared to most synthetic fibers, making it more environmentally friendly but less durable under repeated washing or exposure to sunlight. Conversely, synthetic fibers excel in elasticity, color retention, and resistance to wrinkles, positioning them as preferable for activewear and long-lasting textiles.

Environmental Impact: Semi-Synthetic vs Synthetic

Rayon, a semi-synthetic fiber derived from natural cellulose, offers a biodegradable alternative to fully synthetic fibers like polyester and nylon, which primarily originate from petrochemicals and contribute significantly to microplastic pollution. The production of rayon involves chemical-intensive processes that can generate hazardous waste and consume large volumes of water, yet it generally has a lower carbon footprint compared to synthetic fibers requiring fossil fuel extraction and processing. Choosing semi-synthetic rayon reduces reliance on non-renewable resources and supports biodegradability but requires stricter environmental management to mitigate chemical pollution during manufacturing.

Durability and Performance Comparison

Semi-synthetic rayon fibers, derived from regenerated cellulose, offer moderate durability but often absorb moisture, which can reduce strength and cause shrinkage over time. Synthetic fibers such as polyester and nylon provide superior durability, resistance to stretching, and consistent performance under varying environmental conditions. When comparing performance, synthetic fibers outperform rayon in terms of abrasion resistance, longevity, and water repellency, making them more suitable for heavy-duty applications.

Cost Factors in Semi-Synthetic and Synthetic Products

Semi-synthetic fibers like rayon generally incur lower production costs due to the use of natural cellulose sources and less energy-intensive manufacturing processes compared to fully synthetic fibers such as polyester. Synthetic fibers demand higher capital investment for petrochemical raw materials, complex polymerization, and extrusion techniques. Cost factors also reflect differences in raw material availability, environmental regulations, and energy consumption impacting overall pricing strategies in textile manufacturing.

Comfort and Texture: How Rayon Measures Up

Rayon offers superior breathability and softness compared to many synthetic fibers, making it a favored choice for comfortable clothing. Its semi-synthetic nature allows it to mimic the natural texture of cotton or silk, providing a smooth and lightweight feel. In contrast, synthetic fibers like polyester often lack this natural texture, leading to less comfort and poorer moisture absorption.

Uses of Rayon in Modern Textiles

Rayon, classified as a semi-synthetic fiber derived from cellulose, combines the natural qualities of cotton with the versatility of synthetic fibers, making it widely used in modern textiles for clothing, upholstery, and industrial fabrics. Unlike fully synthetic fibers such as polyester, rayon offers superior breathability and moisture absorption, enhancing comfort in fashion and activewear. Its adaptability in dyeing and blending with other fibers expands its applications across fashion, home decor, and technical textiles.

Sustainability and Eco-Friendliness in Fiber Choices

Semi-synthetic fibers like rayon are derived from natural cellulose sources such as wood pulp, offering biodegradability and reduced reliance on fossil fuels compared to fully synthetic fibers like polyester, which are petroleum-based and contribute significantly to microplastic pollution. Rayon production has evolved with eco-friendlier processes such as lyocell technology that uses non-toxic solvents and closed-loop systems to minimize environmental impact. Choosing semi-synthetic fibers enhances sustainability in textile manufacturing by balancing renewable raw materials with improved manufacturing methods that lower water use and chemical waste.

Choosing the Right Fiber: Semi-Synthetic or Synthetic?

Choosing the right fiber depends on the desired properties and environmental impact, where semi-synthetic fibers like rayon offer breathability and biodegradability derived from natural cellulose, making them suitable for sustainable fashion. Synthetic fibers such as polyester and nylon, made from petrochemicals, provide durability, moisture resistance, and cost-effectiveness but raise concerns about microplastic pollution. Evaluating factors like comfort, performance, and ecological footprint is crucial when deciding between semi-synthetic rayon and fully synthetic alternatives.

Semi-Synthetic vs Synthetic Infographic

materialdif.com

materialdif.com