Solvent-spun rayon uses a chemical solvent to dissolve cellulose, producing fibers with higher strength, smoother texture, and greater uniformity compared to viscose process rayon. The viscose process rayon involves treating cellulose with carbon disulfide and sodium hydroxide, which yields fibers with good softness and drape but lower environmental sustainability. Solvent-spun rayon offers a more eco-friendly alternative with improved fiber performance, making it ideal for sustainable textile applications.

Table of Comparison

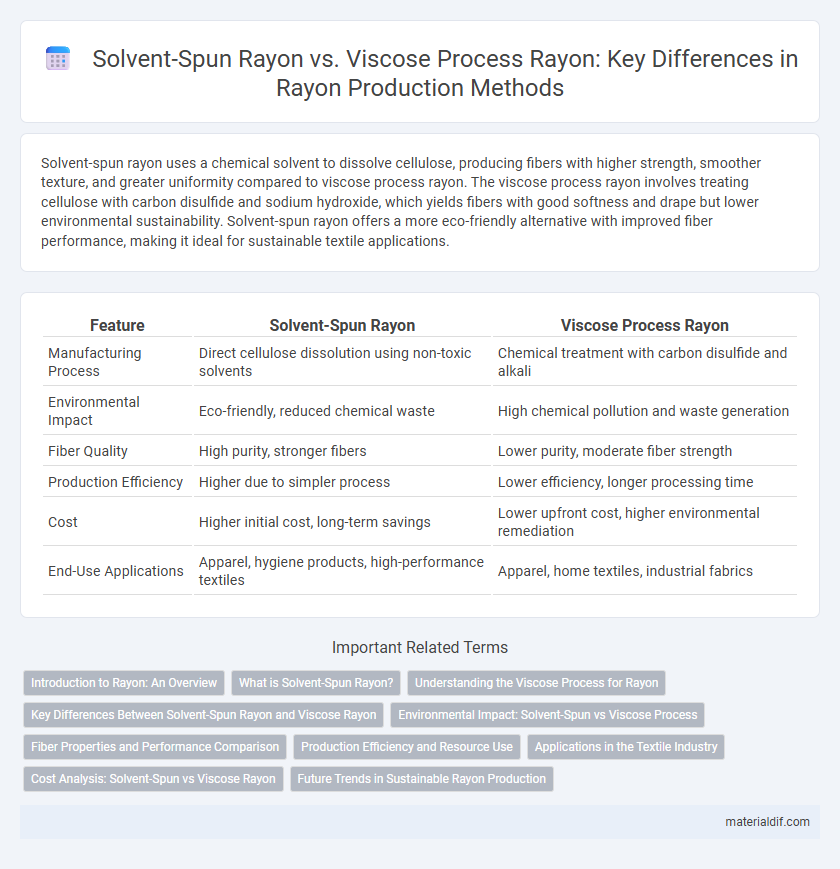

| Feature | Solvent-Spun Rayon | Viscose Process Rayon |

|---|---|---|

| Manufacturing Process | Direct cellulose dissolution using non-toxic solvents | Chemical treatment with carbon disulfide and alkali |

| Environmental Impact | Eco-friendly, reduced chemical waste | High chemical pollution and waste generation |

| Fiber Quality | High purity, stronger fibers | Lower purity, moderate fiber strength |

| Production Efficiency | Higher due to simpler process | Lower efficiency, longer processing time |

| Cost | Higher initial cost, long-term savings | Lower upfront cost, higher environmental remediation |

| End-Use Applications | Apparel, hygiene products, high-performance textiles | Apparel, home textiles, industrial fabrics |

Introduction to Rayon: An Overview

Solvent-spun rayon, often known as lyocell, utilizes a non-toxic organic solvent for cellulose dissolution, resulting in a more environmentally friendly process compared to the viscose method. The viscose process rayon involves treating cellulose with carbon disulfide and sodium hydroxide, producing softer and more absorbent fibers but generating significant chemical waste. Both types of rayon are regenerated cellulose fibers derived from wood pulp, with solvent-spun rayon offering enhanced strength and biodegradability over traditional viscose.

What is Solvent-Spun Rayon?

Solvent-spun rayon is a type of regenerated cellulose fiber produced using a closed-loop solvent spinning process that dissolves cellulose without chemical derivatization, preserving the polymer's natural structure. Unlike the viscose process rayon, which involves chemical treatment with carbon disulfide and alkali, solvent-spun rayon utilizes environmentally friendly solvents such as N-Methylmorpholine N-oxide (NMMO) to extract cellulose. This method results in fibers with superior strength, higher purity, and reduced environmental impact due to solvent recovery and minimal waste generation.

Understanding the Viscose Process for Rayon

The viscose process for producing rayon involves chemically treating cellulose with sodium hydroxide and carbon disulfide to form a viscous solution known as viscose, which is then extruded through spinnerets to create fibers. This method allows for precise control over fiber properties such as strength, luster, and absorbency, making it suitable for various textile applications. Compared to solvent-spun rayon, the viscose process is more widely used industrially due to its scalability and ability to produce diverse fiber types.

Key Differences Between Solvent-Spun Rayon and Viscose Rayon

Solvent-spun rayon uses non-toxic solvents to dissolve cellulose, resulting in a cleaner production process with fewer environmental pollutants compared to the viscose process that employs carbon disulfide, a hazardous chemical. The solvent-spun method produces fibers with higher tensile strength and better uniformity, enhancing fabric durability and texture. Viscose rayon typically offers lower production costs but compromises on environmental impact and fiber quality, making solvent-spun rayon a more sustainable and premium alternative.

Environmental Impact: Solvent-Spun vs Viscose Process

Solvent-spun rayon utilizes a closed-loop system that recycles nearly 99% of solvents, drastically reducing toxic emissions and water contamination compared to the traditional viscose process. The viscose process involves hazardous chemicals like carbon disulfide and releases significant effluents, contributing to air and water pollution. Solvent-spun rayon offers a more sustainable alternative by minimizing chemical waste and lowering the environmental footprint of rayon production.

Fiber Properties and Performance Comparison

Solvent-spun rayon, produced through the lyocell process, exhibits superior fiber properties such as higher tensile strength, enhanced moisture absorbency, and greater dimensional stability compared to viscose process rayon. The lyocell fibers have a smoother surface morphology, resulting in less fibrillation and improved durability in textile applications. Viscose rayon, while cost-effective and widely used, tends to have lower wet strength and higher environmental impact due to chemical processing differences.

Production Efficiency and Resource Use

Solvent-spun rayon production offers higher efficiency by using direct solvent spinning methods that reduce chemical consumption and energy use compared to the viscose process. The viscose process involves multiple chemical treatments and large water usage, resulting in increased waste and environmental impact. Solvent-spun rayon techniques enhance resource use by recycling solvents and minimizing toxic byproducts, contributing to a more sustainable production cycle.

Applications in the Textile Industry

Solvent-spun rayon offers superior fiber strength and durability, making it ideal for high-performance textiles such as activewear and industrial fabrics. Viscose process rayon, characterized by its softness and versatility, is widely used in apparel, home textiles, and upholstery due to its breathable and comfortable properties. Both fibers serve key roles in the textile industry, with solvent-spun rayon favored for technical applications and viscose rayon dominating fashion and interior textiles.

Cost Analysis: Solvent-Spun vs Viscose Rayon

Solvent-spun rayon generally incurs higher production costs due to the expensive solvents and advanced recovery systems required, while viscose process rayon benefits from a more established infrastructure and lower raw material expenses. Despite higher initial investments, solvent-spun rayon offers improved environmental compliance and fiber quality, potentially reducing long-term operational costs. Viscose rayon remains cost-effective for large-scale production but faces increasing regulatory and waste management expenses that impact overall profitability.

Future Trends in Sustainable Rayon Production

Future trends in sustainable rayon production emphasize solvent-spun rayon due to its eco-friendly attributes, including reduced chemical consumption and lower water usage compared to the traditional viscose process. Innovations in closed-loop solvent spinning technologies enhance resource efficiency and minimize environmental impact by recycling solvents and generating less pollution. The shift towards solvent-spun rayon reflects increasing industry commitments to sustainable textile manufacturing and stricter environmental regulations.

Solvent-spun rayon vs Viscose process rayon Infographic

materialdif.com

materialdif.com