Wet strength rayon exhibits significantly enhanced durability and resistance to stretching when exposed to moisture compared to regular rayon, making it ideal for applications requiring fabric integrity in wet conditions. This specialized rayon undergoes chemical treatments that improve its fiber bonding, preventing the typical weakening and loss of shape seen in conventional rayon when wet. As a result, wet strength rayon is preferred in hygiene products, medical textiles, and other uses demanding superior performance under damp or humid environments.

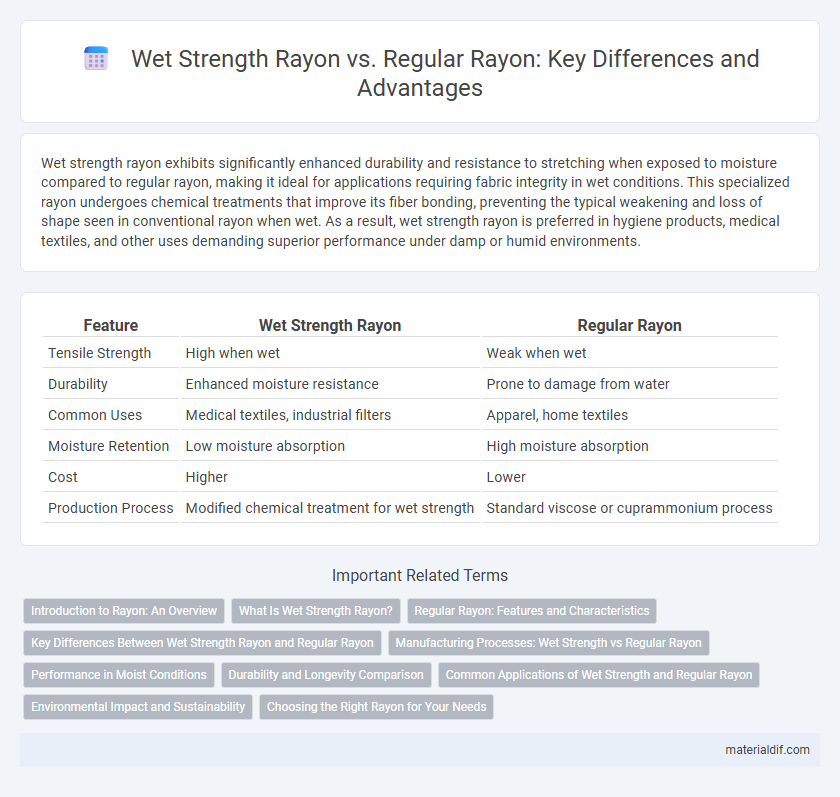

Table of Comparison

| Feature | Wet Strength Rayon | Regular Rayon |

|---|---|---|

| Tensile Strength | High when wet | Weak when wet |

| Durability | Enhanced moisture resistance | Prone to damage from water |

| Common Uses | Medical textiles, industrial filters | Apparel, home textiles |

| Moisture Retention | Low moisture absorption | High moisture absorption |

| Cost | Higher | Lower |

| Production Process | Modified chemical treatment for wet strength | Standard viscose or cuprammonium process |

Introduction to Rayon: An Overview

Rayon, a versatile regenerated cellulose fiber, exhibits enhanced durability when wet through variations like Wet Strength Rayon, which incorporates chemical treatments to improve water resistance and maintain tensile strength. Regular Rayon, while soft and breathable, tends to lose significant strength when wet, limiting its use in moisture-prone applications. The development of Wet Strength Rayon addresses these limitations, expanding its suitability for industrial and textile products requiring sustained performance under wet conditions.

What Is Wet Strength Rayon?

Wet strength rayon is a modified form of rayon fabric engineered to retain its tensile strength and durability when exposed to water, unlike regular rayon which weakens and loses shape upon wetting. Wet strength rayon fibers undergo chemical treatments that enhance their wet tensile properties, making them ideal for applications requiring moisture resistance such as medical textiles, hygiene products, and wipes. This specialized rayon maintains structural integrity and dimensional stability even in high-humidity environments, providing superior performance compared to standard rayon.

Regular Rayon: Features and Characteristics

Regular Rayon is a semi-synthetic fiber known for its smooth texture, high absorbency, and excellent drape, making it popular in apparel and home textiles. It exhibits moderate strength when dry but significantly loses tensile strength when wet, which limits its use in applications requiring durability under moisture exposure. Its biodegradability and ability to blend well with other fibers contribute to its versatility and eco-friendly appeal in textile manufacturing.

Key Differences Between Wet Strength Rayon and Regular Rayon

Wet strength rayon exhibits enhanced durability and improved tensile strength when exposed to moisture, making it ideal for applications requiring fabric performance in wet conditions. Regular rayon tends to lose its structural integrity and weakens significantly upon contact with water due to its hydrophilic nature. The key difference lies in the chemical treatment and cross-linking processes applied to wet strength rayon, which provide superior water resistance compared to standard rayon fibers.

Manufacturing Processes: Wet Strength vs Regular Rayon

Wet strength rayon undergoes a specialized manufacturing process involving crosslinking agents that enhance fiber durability when exposed to moisture, unlike regular rayon produced through the conventional viscose method without such chemical modifications. The wet strength process incorporates resin treatment during the spinning or finishing stages, enabling fibers to retain structural integrity and tensile strength in wet conditions. This chemical reinforcement differentiates wet strength rayon by providing superior resistance to water-induced weakening compared to regular rayon, which tends to lose strength and dimension stability when wet.

Performance in Moist Conditions

Wet strength rayon exhibits significantly enhanced durability and tensile strength in moist conditions compared to regular rayon, making it ideal for applications involving frequent exposure to water or humidity. Its superior molecular bonding resists weakening when wet, ensuring consistent structural integrity and reduced fabric deformation. This performance advantage extends the lifespan and reliability of products such as wipes, surgical gowns, and industrial textiles where moisture resistance is critical.

Durability and Longevity Comparison

Wet strength rayon exhibits significantly enhanced durability compared to regular rayon, maintaining its tensile strength when exposed to moisture, which prevents fabric weakening and tearing during washing or wet conditions. The chemical treatments used in wet strength rayon increase fiber resilience, resulting in longer fabric lifespan and better performance in applications such as hygiene products, industrial wipes, and outdoor textiles. Regular rayon, while soft and breathable, tends to lose up to 50% of its dry strength when wet, leading to reduced longevity and increased susceptibility to damage over time.

Common Applications of Wet Strength and Regular Rayon

Wet strength rayon is widely used in products requiring durability and moisture resistance, such as medical dressings, wipes, and industrial filters. Regular rayon excels in applications prioritizing softness and breathability, making it ideal for apparel, upholstery fabrics, and lightweight home textiles. The choice between wet strength and regular rayon depends on the specific performance requirements, including tensile strength and water absorption.

Environmental Impact and Sustainability

Wet strength rayon offers enhanced durability in moist conditions, reducing the need for frequent replacements and minimizing waste compared to regular rayon. The production of wet strength rayon often involves chemical treatments that may increase environmental impact, whereas regular rayon typically requires fewer chemical additives, leading to lower toxicity and pollution. Sustainable practices in sourcing cellulose and adopting closed-loop processing are critical factors that improve the environmental footprint of both wet strength and regular rayon fibers.

Choosing the Right Rayon for Your Needs

Wet strength rayon offers enhanced durability and maintains its structural integrity when exposed to moisture, making it ideal for applications requiring frequent washing or high humidity environments. Regular rayon, while softer and more breathable, tends to weaken when wet and is better suited for dry conditions or apparel that does not undergo heavy moisture exposure. Selecting between wet strength rayon and regular rayon depends on the specific needs for water resistance, durability, and fabric performance in your intended use.

Wet Strength Rayon vs Regular Rayon Infographic

materialdif.com

materialdif.com