Eco-friendly rayon is produced using sustainable raw materials and environmentally responsible processes that reduce water and energy consumption compared to conventional rayon production. Conventional rayon often relies on chemically intensive methods and non-renewable resources, contributing to pollution and deforestation. Choosing eco-friendly rayon supports a lower carbon footprint and promotes circular fashion practices.

Table of Comparison

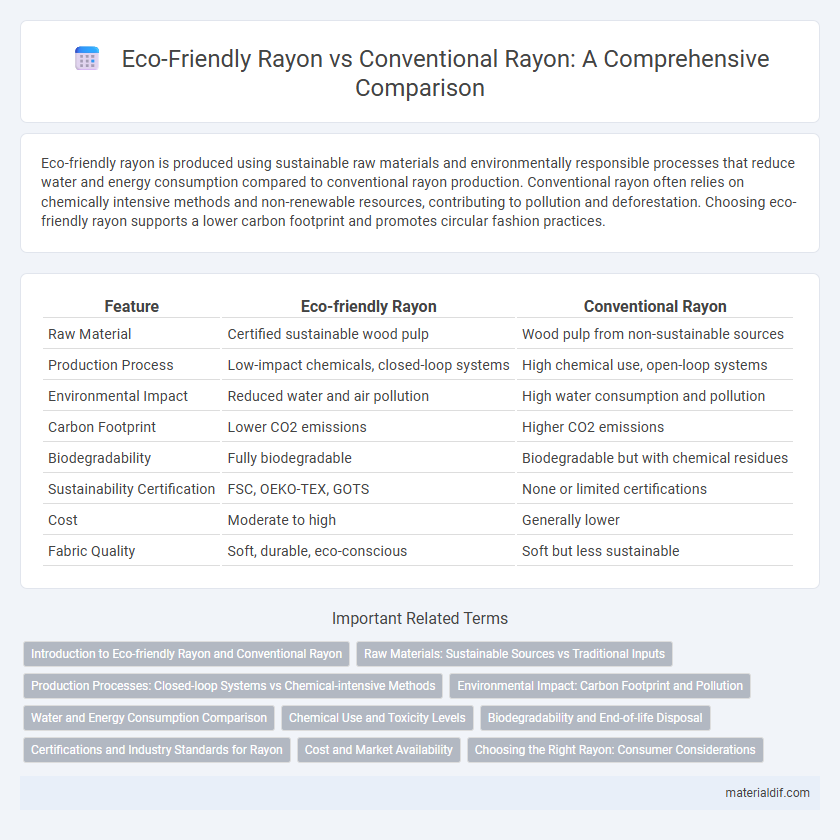

| Feature | Eco-friendly Rayon | Conventional Rayon |

|---|---|---|

| Raw Material | Certified sustainable wood pulp | Wood pulp from non-sustainable sources |

| Production Process | Low-impact chemicals, closed-loop systems | High chemical use, open-loop systems |

| Environmental Impact | Reduced water and air pollution | High water consumption and pollution |

| Carbon Footprint | Lower CO2 emissions | Higher CO2 emissions |

| Biodegradability | Fully biodegradable | Biodegradable but with chemical residues |

| Sustainability Certification | FSC, OEKO-TEX, GOTS | None or limited certifications |

| Cost | Moderate to high | Generally lower |

| Fabric Quality | Soft, durable, eco-conscious | Soft but less sustainable |

Introduction to Eco-friendly Rayon and Conventional Rayon

Eco-friendly rayon is produced using sustainable raw materials like bamboo, hemp, or certified wood pulp, often employing closed-loop production processes that minimize chemical emissions and water usage. Conventional rayon typically derives from wood pulp sourced from unsustainable forestry practices, involving chemically intensive methods that generate significant environmental pollution. Choosing eco-friendly rayon supports reduced carbon footprint and promotes responsible resource management compared to traditional rayon manufacturing.

Raw Materials: Sustainable Sources vs Traditional Inputs

Eco-friendly rayon is produced from sustainably sourced raw materials such as bamboo, organic cotton, and fast-growing eucalyptus trees, reducing deforestation and minimizing environmental impact. Conventional rayon typically relies on wood pulp from unsustainable logging practices that contribute to habitat destruction and carbon emissions. Using sustainable sources promotes biodiversity preservation and lowers the carbon footprint in the textile production process.

Production Processes: Closed-loop Systems vs Chemical-intensive Methods

Eco-friendly rayon utilizes closed-loop production systems that recycle water and solvents, drastically reducing environmental pollution and resource consumption. Conventional rayon relies on chemical-intensive methods involving toxic solvents like carbon disulfide, which pose significant health risks and generate hazardous waste. The shift towards closed-loop technology in eco-friendly rayon manufacturing exemplifies sustainable innovation by minimizing chemical discharge and enhancing resource efficiency.

Environmental Impact: Carbon Footprint and Pollution

Eco-friendly rayon significantly reduces environmental impact by using sustainable raw materials and eco-conscious production methods that lower carbon footprints by up to 40% compared to conventional rayon. Conventional rayon processes rely heavily on toxic chemicals like carbon disulfide, contributing to water pollution and hazardous air emissions. Transitioning to eco-friendly rayon decreases both greenhouse gas emissions and harmful effluents, promoting a cleaner textile industry.

Water and Energy Consumption Comparison

Eco-friendly rayon production significantly reduces water consumption by up to 50% compared to conventional rayon, conserving vital freshwater resources. Energy usage in eco-friendly rayon manufacturing is optimized through renewable sources and efficient technologies, resulting in approximately 40% lower energy consumption. These improvements contribute to a more sustainable textile industry by minimizing environmental impact and promoting resource conservation.

Chemical Use and Toxicity Levels

Eco-friendly rayon uses a closed-loop production process that recycles chemicals such as sodium hydroxide and carbon disulfide, significantly reducing environmental pollution and toxicity levels. Conventional rayon production relies heavily on toxic chemicals like carbon disulfide and sulfuric acid, which often escape into the environment, posing health risks to workers and ecosystems. The closed-loop method in eco-friendly rayon minimizes chemical waste and emissions, making it a safer and more sustainable choice compared to conventional rayon.

Biodegradability and End-of-life Disposal

Eco-friendly rayon is produced using sustainable raw materials and processes that minimize chemical use, enhancing its biodegradability compared to conventional rayon. Unlike conventional rayon, which often involves toxic solvents and chemicals during production, eco-friendly rayon breaks down more easily in natural environments, reducing landfill burden and ecological impact. End-of-life disposal of eco-friendly rayon products results in less soil and water contamination, promoting a circular textile economy.

Certifications and Industry Standards for Rayon

Eco-friendly rayon is produced using sustainable raw materials and eco-conscious processes verified by certifications such as OEKO-TEX Standard 100, FSC (Forest Stewardship Council), and PEFC (Programme for the Endorsement of Forest Certification). Conventional rayon often lacks these certifications, relying on traditional chemical-intensive methods that pose higher environmental risks. Industry standards like the LENZING(tm) viscose certification promote transparency and responsible manufacturing practices, setting eco-friendly rayon apart in terms of environmental impact and traceability.

Cost and Market Availability

Eco-friendly rayon often incurs higher production costs due to sustainable raw materials and environmentally responsible manufacturing processes, leading to a comparatively higher market price than conventional rayon. Conventional rayon benefits from established supply chains and large-scale production, ensuring widespread availability and lower costs in global textile markets. Consumer demand for sustainable products is gradually increasing market presence and competitive pricing of eco-friendly rayon.

Choosing the Right Rayon: Consumer Considerations

Eco-friendly rayon, produced from sustainably sourced cellulose and employing closed-loop manufacturing processes, significantly reduces environmental impact compared to conventional rayon, which relies on heavy chemical treatments and often contributes to deforestation. Consumers should prioritize certifications such as FSC or OEKO-TEX to ensure the rayon's sustainability credentials and assess the product lifecycle, including water usage and carbon footprint. Selecting eco-friendly rayon supports responsible forest management and minimizes pollution, aligning with growing demand for sustainable textiles in fashion and home goods.

Eco-friendly Rayon vs Conventional Rayon Infographic

materialdif.com

materialdif.com