High-tenacity Rayon offers superior strength and durability compared to regular Rayon, making it ideal for demanding textile applications. Its enhanced fiber structure provides improved resistance to wear and tear, ensuring longer-lasting performance in garments and industrial fabrics. This advanced version maintains the softness and breathability of regular Rayon while delivering significantly greater tensile strength.

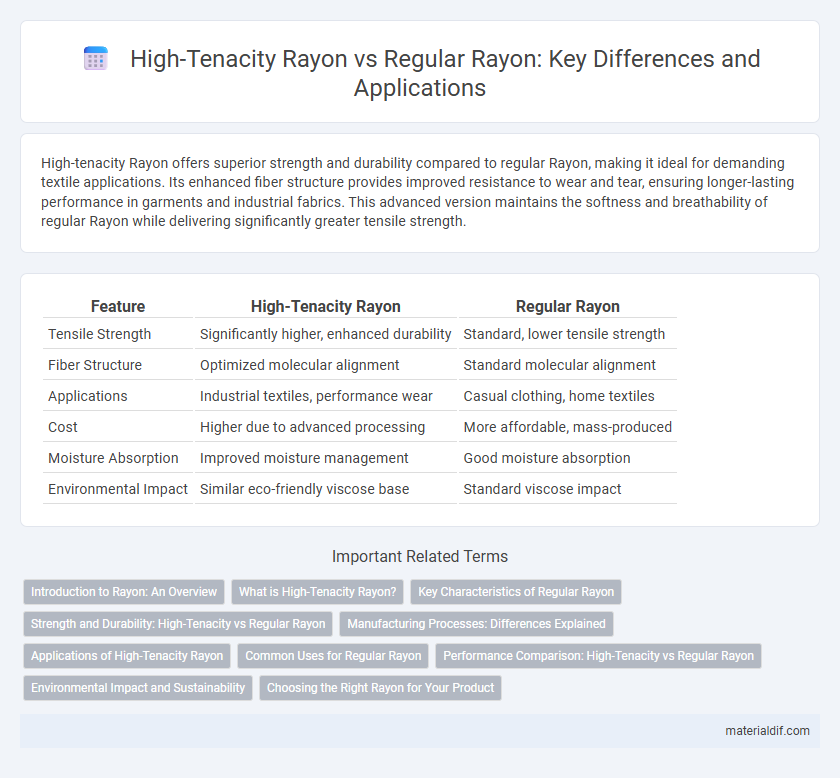

Table of Comparison

| Feature | High-Tenacity Rayon | Regular Rayon |

|---|---|---|

| Tensile Strength | Significantly higher, enhanced durability | Standard, lower tensile strength |

| Fiber Structure | Optimized molecular alignment | Standard molecular alignment |

| Applications | Industrial textiles, performance wear | Casual clothing, home textiles |

| Cost | Higher due to advanced processing | More affordable, mass-produced |

| Moisture Absorption | Improved moisture management | Good moisture absorption |

| Environmental Impact | Similar eco-friendly viscose base | Standard viscose impact |

Introduction to Rayon: An Overview

Rayon, a versatile semi-synthetic fiber derived from cellulose, is widely used in textiles due to its silk-like feel and breathability. High-tenacity rayon differs from regular rayon by its enhanced tensile strength and durability, achieved through advanced molecular alignment and processing techniques. This improved fiber strength allows high-tenacity rayon to be ideal for industrial applications and performance fabrics where durability is critical.

What is High-Tenacity Rayon?

High-tenacity rayon is a type of regenerated cellulose fiber engineered for superior tensile strength and durability compared to regular rayon. It undergoes specialized chemical and mechanical processes that increase fiber orientation and molecular alignment, resulting in enhanced resistance to wear and tear. This makes high-tenacity rayon ideal for industrial applications, technical textiles, and performance wear where durability and longevity are critical.

Key Characteristics of Regular Rayon

Regular rayon features moderate tensile strength, making it less durable compared to high-tenacity rayon, which is engineered for enhanced durability. Its natural fiber structure offers excellent moisture absorption and breathability, ideal for comfort-oriented textiles. The lower tenacity results in regular rayon being more prone to stretching and wear under heavy stress or repeated use.

Strength and Durability: High-Tenacity vs Regular Rayon

High-tenacity rayon offers superior strength and durability compared to regular rayon, making it ideal for applications requiring enhanced tensile resistance. The fiber structure in high-tenacity rayon is engineered for increased polymer alignment, resulting in greater mechanical performance and prolonged lifespan under stress. Regular rayon tends to be less resilient, with lower tensile strength and quicker degradation when subjected to heavy use or abrasion.

Manufacturing Processes: Differences Explained

High-tenacity rayon undergoes a specialized manufacturing process involving enhanced chemical treatments and controlled fiber orientation to increase tensile strength and durability compared to regular rayon. The spinning method for high-tenacity rayon often uses filaments aligned more uniformly, resulting in fibers with superior mechanical properties. Regular rayon is produced via conventional viscose processing with less emphasis on fiber alignment, yielding softer but weaker fibers suitable for standard textile applications.

Applications of High-Tenacity Rayon

High-tenacity rayon exhibits superior tensile strength and durability compared to regular rayon, making it ideal for industrial applications such as tire cords, conveyor belts, and military fabrics. Its enhanced resistance to abrasion and stretching ensures longer lifespan in demanding environments, including automotive and aerospace sectors. High-tenacity rayon also plays a critical role in technical textiles requiring high performance and reliability under stress.

Common Uses for Regular Rayon

Regular rayon is widely used in apparel such as dresses, blouses, and linings due to its soft texture and breathability. It is also popular in home textiles including curtains and upholstery because of its excellent dye absorption and vibrant color retention. Common applications extend to disposable products like hygiene items and medical fabrics, leveraging its high moisture absorbency.

Performance Comparison: High-Tenacity vs Regular Rayon

High-tenacity rayon exhibits superior tensile strength and durability compared to regular rayon, making it ideal for demanding textile applications. Its enhanced molecular orientation results in better resistance to abrasion and stretching, which significantly prolongs fabric lifespan. Regular rayon, while softer and more breathable, lacks the robustness required for high-performance or industrial-grade products.

Environmental Impact and Sustainability

High-tenacity rayon features enhanced fiber strength, allowing for longer product lifespan and reduced material waste compared to regular rayon, which often requires more frequent replacement. The production of high-tenacity rayon typically involves optimized chemical processes that lower water and energy consumption, improving overall environmental performance. Sustainable practices in manufacturing high-tenacity rayon contribute to decreased carbon emissions and support circular economy initiatives more effectively than conventional rayon production.

Choosing the Right Rayon for Your Product

High-tenacity rayon offers superior tensile strength and durability compared to regular rayon, making it ideal for products requiring enhanced performance and longevity, such as industrial textiles and high-wear apparel. Its improved fiber structure resists stretching and abrasion, ensuring consistent quality in demanding applications. Choosing high-tenacity rayon over regular rayon enhances product reliability, particularly where strength and durability are critical factors.

High-tenacity Rayon vs Regular Rayon Infographic

materialdif.com

materialdif.com