Solvent spun rayon offers superior fiber strength and smoothness due to the use of non-acidic solvents in the production process, resulting in higher quality and durability. Acid spun rayon, produced using sulfuric acid, tends to have weaker fibers and lower resistance to moisture, making it less suitable for high-performance textile applications. Choosing solvent spun rayon enhances fabric longevity and maintains structural integrity under various environmental conditions.

Table of Comparison

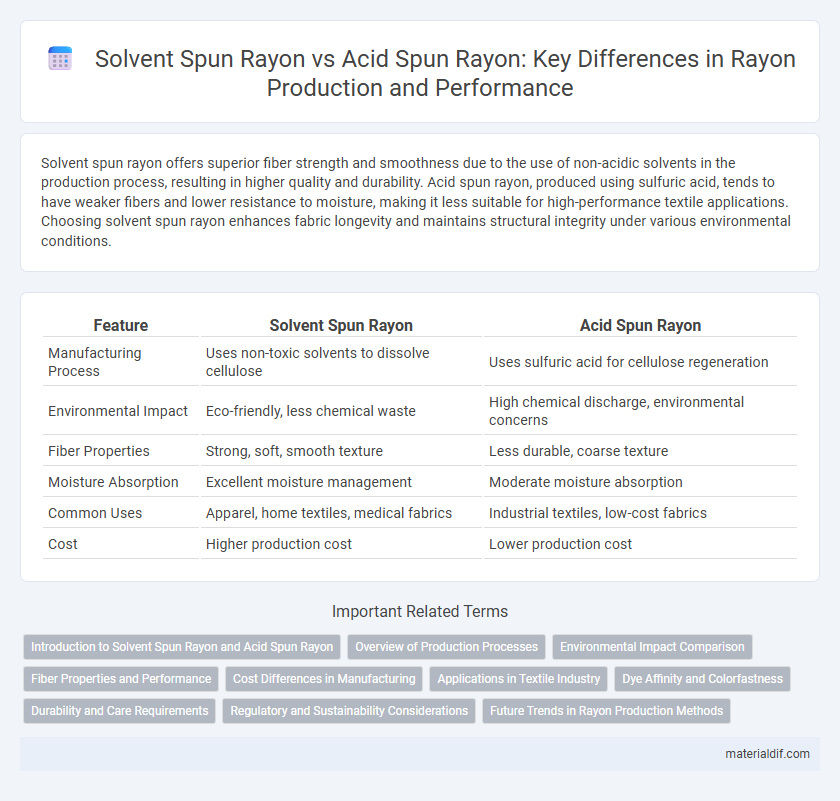

| Feature | Solvent Spun Rayon | Acid Spun Rayon |

|---|---|---|

| Manufacturing Process | Uses non-toxic solvents to dissolve cellulose | Uses sulfuric acid for cellulose regeneration |

| Environmental Impact | Eco-friendly, less chemical waste | High chemical discharge, environmental concerns |

| Fiber Properties | Strong, soft, smooth texture | Less durable, coarse texture |

| Moisture Absorption | Excellent moisture management | Moderate moisture absorption |

| Common Uses | Apparel, home textiles, medical fabrics | Industrial textiles, low-cost fabrics |

| Cost | Higher production cost | Lower production cost |

Introduction to Solvent Spun Rayon and Acid Spun Rayon

Solvent spun rayon is produced by dissolving cellulose in a solvent to form a viscous solution, which is then extruded through spinnerets to create fibers with high purity and uniformity. Acid spun rayon involves treating cellulose with acid solutions, typically copper or ammonium-based, to regenerate fibers through coagulation, resulting in a distinct molecular structure and enhanced dye affinity. Both methods convert cellulose into rayon fibers, but solvent spinning offers superior control over fiber morphology and fewer environmental contaminants compared to acid spinning.

Overview of Production Processes

Solvent spun rayon is produced by dissolving cellulose in a solvent such as N-Methylmorpholine N-oxide, followed by extrusion and regeneration of fibers, ensuring a more environmentally friendly and efficient process. Acid spun rayon involves treating cellulose with acid solutions, typically sulfuric acid, to dissolve and regenerate fibers, often resulting in inferior fiber strength and durability compared to solvent spun fibers. The production process of solvent spun rayon typically offers enhanced control over fiber properties, making it preferable in high-performance textile applications.

Environmental Impact Comparison

Solvent spun rayon uses non-toxic solvents that can be recovered and recycled, resulting in less harmful emissions and lower water pollution compared to acid spun rayon, which relies on strong mineral acids generating hazardous waste and acid runoff. The closed-loop processes in solvent spinning significantly reduce environmental footprint by minimizing chemical discharge and energy consumption. In contrast, acid spun rayon often requires extensive wastewater treatment and contributes to soil and water acidification due to residual acid waste.

Fiber Properties and Performance

Solvent spun rayon exhibits superior fiber strength and luster due to its production process using N-methylmorpholine N-oxide, resulting in high tenacity and dimensional stability compared to acid spun rayon, which is produced by steeping cellulose in sulfuric acid solutions. Acid spun rayon tends to have lower tensile strength and reduced durability but offers better moisture absorption and softness, making it suitable for textile applications requiring enhanced comfort. Solvent spun rayon fibers demonstrate improved resistance to shrinkage and enhanced dye uptake, contributing to longer-lasting and vibrant fabric performance.

Cost Differences in Manufacturing

Solvent spun rayon typically incurs higher manufacturing costs due to the use of specialized solvents and intricate recovery systems, resulting in energy-intensive processes. In contrast, acid spun rayon benefits from lower raw material expenses and simpler chemical treatments, reducing overall production costs. These cost differences significantly influence the choice of rayon manufacturing methods in industrial applications.

Applications in Textile Industry

Solvent spun rayon, known for its high tensile strength and uniform fiber structure, is widely used in high-performance textiles and industrial fabrics where durability and resistance to chemicals are critical. Acid spun rayon, produced through acid hydrolysis, offers superior moisture absorption and softness, making it ideal for comfortable apparel and hygiene products. Both types of rayon enhance the versatility of textile applications, with solvent spun rayon favored for technical textiles and acid spun rayon preferred in fashion and personal care industries.

Dye Affinity and Colorfastness

Solvent spun rayon exhibits superior dye affinity due to its uniform fiber structure, allowing for vibrant and even color absorption. Acid spun rayon tends to have lower dye affinity, resulting in less intense coloration and uneven dye uptake. Colorfastness in solvent spun rayon is generally higher, with enhanced resistance to fading and washing compared to the more delicate, less durable acid spun fibers.

Durability and Care Requirements

Solvent spun rayon, produced through a closed-loop process using non-toxic solvents like N-Methylmorpholine N-oxide, offers enhanced durability with stronger fiber integrity compared to acid spun rayon, which relies on acidic solutions and tends to weaken fibers. Care requirements for solvent spun rayon are more manageable, as its higher tensile strength resists shrinkage and deformation during washing, while acid spun rayon demands gentler handling and often dry cleaning to maintain fabric quality. The environmental benefits of solvent spinning complement its superior durability, making it a preferred choice for long-lasting, easy-care textiles.

Regulatory and Sustainability Considerations

Solvent spun rayon uses non-toxic solvents like N-Methylmorpholine N-oxide (NMMO), which allows closed-loop processes minimizing environmental impact and meeting stringent REACH and EPA regulations. Acid spun rayon, produced with highly concentrated sulfuric acid, poses significant risks due to acid handling, waste disposal challenges, and stricter environmental controls under OSHA and EPA standards. Sustainable practices favor solvent spun rayon for its solvent recovery efficiency and lower hazardous chemical emissions, aligning with global sustainability frameworks such as the Sustainable Apparel Coalition's Higg Index.

Future Trends in Rayon Production Methods

Solvent spun rayon leverages greener solvents and advanced recycling techniques, promising reduced environmental impact and enhanced fiber strength compared to traditional acid spun rayon. Emerging trends emphasize bio-based solvents and closed-loop production systems that minimize chemical waste and energy consumption. Innovations in solvent spun rayon technology are poised to drive sustainable scalability in the textile industry's future.

Solvent Spun Rayon vs Acid Spun Rayon Infographic

materialdif.com

materialdif.com