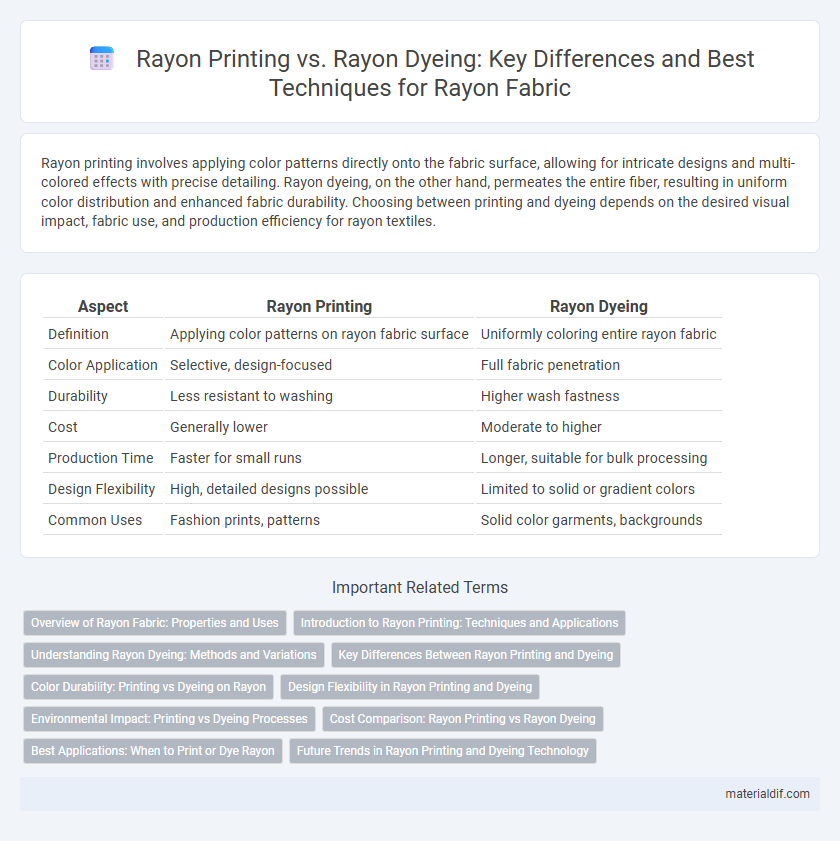

Rayon printing involves applying color patterns directly onto the fabric surface, allowing for intricate designs and multi-colored effects with precise detailing. Rayon dyeing, on the other hand, permeates the entire fiber, resulting in uniform color distribution and enhanced fabric durability. Choosing between printing and dyeing depends on the desired visual impact, fabric use, and production efficiency for rayon textiles.

Table of Comparison

| Aspect | Rayon Printing | Rayon Dyeing |

|---|---|---|

| Definition | Applying color patterns on rayon fabric surface | Uniformly coloring entire rayon fabric |

| Color Application | Selective, design-focused | Full fabric penetration |

| Durability | Less resistant to washing | Higher wash fastness |

| Cost | Generally lower | Moderate to higher |

| Production Time | Faster for small runs | Longer, suitable for bulk processing |

| Design Flexibility | High, detailed designs possible | Limited to solid or gradient colors |

| Common Uses | Fashion prints, patterns | Solid color garments, backgrounds |

Overview of Rayon Fabric: Properties and Uses

Rayon fabric, known for its silky texture and breathability, is a versatile semi-synthetic fiber derived from cellulose. Rayon printing involves applying vibrant designs onto the fabric's surface, enhancing aesthetic appeal, while rayon dyeing ensures uniform color penetration for consistent shading. Commonly used in apparel, home textiles, and upholstery, rayon's moisture absorbency and drape make it ideal for both printing and dyeing processes, depending on the desired visual effect.

Introduction to Rayon Printing: Techniques and Applications

Rayon printing involves applying patterns or designs onto rayon fabric using techniques such as screen printing, rotary printing, and digital printing, which enhance the aesthetic appeal and versatility of the material. These methods allow for vibrant color reproduction and intricate detailing, making rayon printing ideal for fashion, upholstery, and home textiles. Unlike rayon dyeing, which uniformly colors the fabric, printing targets specific areas, enabling complex and multi-colored designs that cater to diverse consumer preferences.

Understanding Rayon Dyeing: Methods and Variations

Rayon dyeing involves soaking or applying dye to rayon fibers to enhance color vibrancy and fastness, with common methods including piece dyeing, yarn dyeing, and garment dyeing. Variations in dyeing techniques affect the texture, color uniformity, and durability of the fabric, with reactive and direct dyes often preferred for their affinity to cellulose-based rayon fibers. Understanding the chemical interactions between dyes and rayon helps in selecting appropriate methods to achieve desired aesthetic and performance qualities.

Key Differences Between Rayon Printing and Dyeing

Rayon printing involves applying patterns or designs onto the fabric's surface using pigments or dyes, preserving the fabric's texture while allowing intricate motifs. Rayon dyeing immerses the entire fabric in a dye bath, ensuring uniform color penetration and consistent hue throughout the material. The key difference lies in printing being surface-focused with varied designs, whereas dyeing results in an all-over, solid coloration of the rayon fabric.

Color Durability: Printing vs Dyeing on Rayon

Rayon dyeing penetrates fibers deeply, resulting in more vibrant colors with superior durability and resistance to fading compared to printing. Rayon printing applies color to the surface, making the design more susceptible to wear and color loss over time. Choosing dyeing enhances the longevity of color intensity, while printing offers intricate patterns but with less resilience.

Design Flexibility in Rayon Printing and Dyeing

Rayon printing offers exceptional design flexibility by allowing intricate patterns and multicolor designs to be applied precisely on the fabric surface without altering its texture. In contrast, rayon dyeing penetrates the fibers, providing uniform color but limited detail control, making it less suitable for complex designs. Choosing between printing and dyeing depends on whether vibrant, detailed imagery or consistent, solid colors are prioritized in the final textile product.

Environmental Impact: Printing vs Dyeing Processes

Rayon printing typically involves applying pigments or dyes directly onto fabric surfaces, resulting in localized chemical use and reduced water consumption compared to dyeing, which immerses the entire fabric and demands significant water and energy resources. Dyeing processes for rayon often lead to extensive wastewater generation containing residual chemicals, contributing to environmental pollution if not properly treated. Printing methods minimize chemical effluent volume but may introduce concerns related to binder substances, emphasizing the need for eco-friendly inks to reduce environmental impact.

Cost Comparison: Rayon Printing vs Rayon Dyeing

Rayon printing generally incurs lower costs compared to rayon dyeing due to reduced material usage and simplified processing steps. Dyeing requires extensive water, chemicals, and energy consumption, increasing overall expenses and environmental impact. Printing methods allow for precise color application, resulting in less waste and more economical fabric decoration.

Best Applications: When to Print or Dye Rayon

Rayon printing is ideal for creating intricate patterns and vibrant designs on lighter fabrics, making it perfect for fashion apparel like blouses and dresses. Rayon dyeing offers deep, uniform color penetration suited for solid-colored garments, upholstery, and home textiles requiring durability and colorfastness. Choosing between printing and dyeing depends on the final product's design complexity and color intensity needs.

Future Trends in Rayon Printing and Dyeing Technology

Future trends in rayon printing and dyeing technology emphasize eco-friendly processes utilizing biodegradable inks and waterless dyeing methods to reduce environmental impact. Innovations in digital textile printing offer enhanced precision and customization, enabling vibrant, durable designs on rayon fabrics with minimal waste. Advancements in nanotechnology and enzymatic treatments also promise improved color fastness and fabric softness, driving sustainable practices in the textile industry.

Rayon Printing vs Rayon Dyeing Infographic

materialdif.com

materialdif.com