Degummed rayon undergoes a process that removes the stiffening gum, resulting in a softer, more flexible fiber ideal for textile applications requiring smoothness and suppleness. Gum-stiffened rayon retains the natural gum, providing enhanced stiffness and durability, making it suitable for industrial uses and products needing structural integrity. Choosing between degummed and gum-stiffened rayon depends on the desired texture and performance characteristics of the final product.

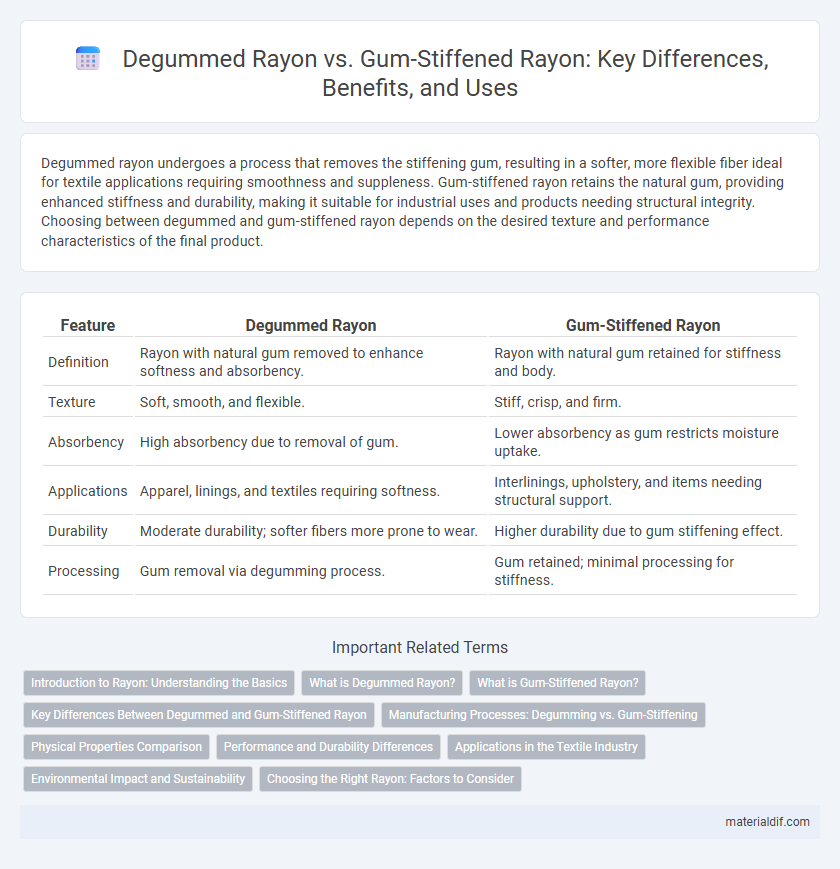

Table of Comparison

| Feature | Degummed Rayon | Gum-Stiffened Rayon |

|---|---|---|

| Definition | Rayon with natural gum removed to enhance softness and absorbency. | Rayon with natural gum retained for stiffness and body. |

| Texture | Soft, smooth, and flexible. | Stiff, crisp, and firm. |

| Absorbency | High absorbency due to removal of gum. | Lower absorbency as gum restricts moisture uptake. |

| Applications | Apparel, linings, and textiles requiring softness. | Interlinings, upholstery, and items needing structural support. |

| Durability | Moderate durability; softer fibers more prone to wear. | Higher durability due to gum stiffening effect. |

| Processing | Gum removal via degumming process. | Gum retained; minimal processing for stiffness. |

Introduction to Rayon: Understanding the Basics

Degummed rayon refers to the type of rayon where the gum, primarily cellulose derivatives like hemicellulose or lignin, is removed to achieve a softer and more flexible fabric suitable for apparel and home textiles. Gum-stiffened rayon retains these gums, resulting in a stiffer texture often used in industrial applications or materials requiring more rigidity. Understanding the difference between degummed and gum-stiffened rayon is essential for selecting the appropriate fabric based on flexibility, strength, and end-use requirements.

What is Degummed Rayon?

Degummed rayon refers to rayon fibers that have undergone a chemical process to remove the natural gum, primarily sericin, from the fiber surface, enhancing softness and flexibility. This treatment improves the fiber's dyeability and luster while reducing stiffness, making it ideal for textile applications requiring a smooth, silky finish. Compared to gum-stiffened rayon, degummed rayon offers better moisture absorption and comfort due to the elimination of the gummy coating.

What is Gum-Stiffened Rayon?

Gum-stiffened rayon is a type of rayon fabric treated with natural gums to enhance its stiffness and texture, providing a crisp hand feel that differentiates it from degummed rayon. Unlike degummed rayon, which has most of the gum removed to create a softer and more drapable fabric, gum-stiffened rayon retains these gums to maintain structure and firmness. This treatment is commonly used in applications requiring a more rigid textile, such as in upholstery and certain apparel where shape retention is crucial.

Key Differences Between Degummed and Gum-Stiffened Rayon

Degummed rayon is characterized by its removal of natural gums, resulting in a softer, more lustrous fabric with enhanced dye absorption and breathability. Gum-stiffened rayon retains the natural gummy substances, providing a stiffer texture and increased durability but reduced flexibility compared to degummed rayon. These key differences influence their applications, with degummed rayon favored in lightweight, comfortable garments and gum-stiffened rayon used in products requiring structural integrity.

Manufacturing Processes: Degumming vs. Gum-Stiffening

Degummed rayon undergoes a chemical process where sericin, a natural gum present in raw fibers, is removed to produce a smoother, softer texture ideal for textile applications. Gum-stiffened rayon retains this sericin coating, which provides enhanced stiffness and durability, making it suitable for uses requiring structural rigidity. The manufacturing processes differ primarily in the treatment of these natural gums--degumming involves washing and chemical extraction to eliminate sericin, while gum-stiffening applies treatments that preserve or augment the gum content for functional performance.

Physical Properties Comparison

Degummed rayon exhibits a softer texture and higher moisture absorption due to the removal of gum, enhancing its flexibility and comfort in textiles. Gum-stiffened rayon retains the natural gummy substance, resulting in increased stiffness, reduced elongation, and lower moisture regain. These physical property differences impact fabric drape, strength, and suitability for applications requiring varied hand and durability.

Performance and Durability Differences

Degummed rayon exhibits superior softness and moisture absorption due to the removal of natural gums, enhancing comfort and breathability in textile applications. In contrast, gum-stiffened rayon retains these gums, resulting in increased rigidity and structural integrity, which improves dimensional stability and resistance to wear in industrial uses. Performance-wise, degummed rayon excels in flexibility and durability in garment production, while gum-stiffened rayon offers enhanced strength and longevity for technical textiles.

Applications in the Textile Industry

Degummed rayon, with its smooth texture and high absorbency, is commonly used in apparel, home textiles, and medical gauze, offering comfort and breathability. Gum-stiffened rayon retains residual gum, providing enhanced stiffness and durability, making it ideal for industrial fabrics, upholstery, and textile reinforcements. The choice between degummed and gum-stiffened rayon depends on the desired balance between softness and structural integrity in textile applications.

Environmental Impact and Sustainability

Degummed rayon, produced by removing sericin from silk fibers, offers greater environmental sustainability due to its biodegradable properties and reduced chemical waste compared to gum-stiffened rayon, which retains gum proteins leading to higher processing emissions. The degumming process uses environmentally friendly enzymes and less water, minimizing pollution and energy consumption, while gum-stiffened rayon often involves synthetic additives that hinder biodegradability and increase ecological footprint. Sustainable textile industries favor degummed rayon for its lower carbon emissions, enhanced recyclability, and support of circular economy principles.

Choosing the Right Rayon: Factors to Consider

Degummed rayon offers a soft, smooth texture ideal for delicate garments, while gum-stiffened rayon provides extra rigidity suited for structured designs. Choosing the right rayon depends on the desired fabric hand, drape quality, and end-use durability, with considerations for breathability and dye absorption. Evaluating the degree of gum removal influences fabric performance in applications ranging from apparel to upholstery.

Degummed Rayon vs Gum-Stiffened Rayon Infographic

materialdif.com

materialdif.com