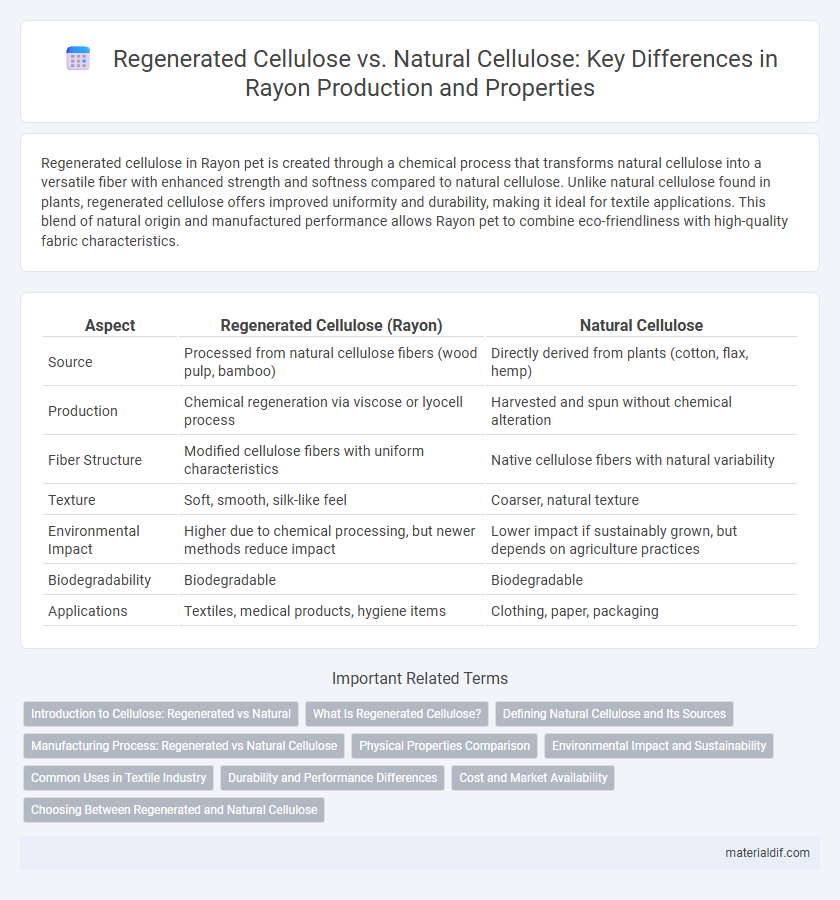

Regenerated cellulose in Rayon pet is created through a chemical process that transforms natural cellulose into a versatile fiber with enhanced strength and softness compared to natural cellulose. Unlike natural cellulose found in plants, regenerated cellulose offers improved uniformity and durability, making it ideal for textile applications. This blend of natural origin and manufactured performance allows Rayon pet to combine eco-friendliness with high-quality fabric characteristics.

Table of Comparison

| Aspect | Regenerated Cellulose (Rayon) | Natural Cellulose |

|---|---|---|

| Source | Processed from natural cellulose fibers (wood pulp, bamboo) | Directly derived from plants (cotton, flax, hemp) |

| Production | Chemical regeneration via viscose or lyocell process | Harvested and spun without chemical alteration |

| Fiber Structure | Modified cellulose fibers with uniform characteristics | Native cellulose fibers with natural variability |

| Texture | Soft, smooth, silk-like feel | Coarser, natural texture |

| Environmental Impact | Higher due to chemical processing, but newer methods reduce impact | Lower impact if sustainably grown, but depends on agriculture practices |

| Biodegradability | Biodegradable | Biodegradable |

| Applications | Textiles, medical products, hygiene items | Clothing, paper, packaging |

Introduction to Cellulose: Regenerated vs Natural

Cellulose is a complex carbohydrate and the primary structural component of plant cell walls, existing naturally in fibers such as cotton and wood. Regenerated cellulose is produced by chemically dissolving natural cellulose and re-forming it into fibers like rayon, which provides enhanced versatility and uniformity. This transformation allows regenerated cellulose to retain the biodegradable and breathable properties of natural cellulose while enabling tailored textile applications.

What Is Regenerated Cellulose?

Regenerated cellulose is a man-made fiber produced by chemically processing natural cellulose extracted from wood pulp or cotton linters, transforming it into a soluble state before re-spinning it into fibers. Unlike natural cellulose, which exists in its original plant-based form, regenerated cellulose undergoes significant treatment to achieve desired textile properties such as enhanced softness, breathability, and biodegradability. Rayon, a common type of regenerated cellulose fiber, bridges the gap between natural and synthetic fabrics by offering sustainability combined with versatile performance characteristics.

Defining Natural Cellulose and Its Sources

Natural cellulose, a polysaccharide composed of b-D-glucose units, is primarily derived from plant cell walls, including cotton, wood, and flax. This biopolymer forms the structural component of plants, making it abundant and renewable. Unlike regenerated cellulose, extracted from raw plant sources without significant chemical alteration, it retains its native molecular structure and crystalline arrangement.

Manufacturing Process: Regenerated vs Natural Cellulose

Regenerated cellulose fibers like rayon are produced by chemically dissolving natural cellulose from wood pulp and then extruding it through a spinneret to form fibers, enabling controlled fiber properties and uniformity. Natural cellulose fibers, such as cotton or flax, are directly harvested from plants without chemical modification, preserving their original fiber structure but with less process control. The manufacturing process of regenerated cellulose involves intensive chemical treatments and regeneration steps, contrasting with the mechanical harvesting and minimal processing of natural cellulose fibers.

Physical Properties Comparison

Regenerated cellulose fibers, such as rayon, exhibit greater uniformity in fiber diameter and improved tensile strength compared to natural cellulose fibers like cotton or flax. These fibers also show enhanced moisture absorbency and a smoother surface texture, contributing to better dye uptake and fabric softness. In contrast, natural cellulose fibers retain higher resilience and greater biodegradability due to their complex microfibril structure.

Environmental Impact and Sustainability

Regenerated cellulose fibers, such as rayon, are produced from natural cellulose sources through chemical processing, which can result in higher water and energy consumption compared to the harvesting of natural cellulose fibers like cotton or linen. While natural cellulose fibers are biodegradable and generally have a lower carbon footprint, rayon's sustainability largely depends on the raw material sourcing and the efficiency of the manufacturing process, including the use of closed-loop systems to minimize chemical discharge. Innovations in producing eco-friendly rayon variants, such as lyocell, emphasize reduced environmental impact by employing non-toxic solvents and sustainable forestry practices.

Common Uses in Textile Industry

Regenerated cellulose fibers like rayon are widely used in the textile industry for fabrics requiring softness, breathability, and drape, commonly found in apparel, home textiles, and upholstery. Natural cellulose fibers such as cotton are preferred for their strength, durability, and moisture absorption, making them ideal for casual wear, denim, and towels. Both types of cellulose fibers offer sustainable alternatives with distinct properties shaping their application in fashion and industrial textiles.

Durability and Performance Differences

Regenerated cellulose fibers such as rayon exhibit lower durability compared to natural cellulose fibers like cotton due to their altered molecular structure, which makes them more prone to weakening when exposed to moisture and mechanical stress. Rayon offers superior softness and drape but tends to have reduced tensile strength and abrasion resistance relative to natural fibers, impacting long-term performance in garments. The chemical processing involved in producing regenerated cellulose results in fibers that generally require more delicate care to maintain their structural integrity over time.

Cost and Market Availability

Regenerated cellulose fibers such as rayon offer a more cost-effective alternative to natural cellulose fibers like cotton due to lower raw material and production costs. Rayon benefits from wide market availability, driven by industrial scalability and the ability to utilize abundant cellulose sources like wood pulp. Natural cellulose fibers face higher volatility in pricing and supply, influenced by agricultural factors and limited growing regions.

Choosing Between Regenerated and Natural Cellulose

Regenerated cellulose fibers such as rayon are manufactured from natural cellulose sources but undergo chemical processing that alters their physical properties, offering enhanced strength and uniformity compared to natural cellulose fibers like cotton or flax. Natural cellulose provides superior breathability and biodegradability, making it ideal for sustainable textile applications, while regenerated cellulose offers versatility and affordability in mass production. Selecting between regenerated and natural cellulose depends on balancing performance requirements, environmental impact, and cost considerations specific to the intended textile use.

Regenerated Cellulose vs Natural Cellulose Infographic

materialdif.com

materialdif.com