Ecovero rayon stands out from conventional rayon by using sustainably sourced wood and eco-friendly production processes that significantly reduce environmental impact. This innovative fiber ensures lower water and energy consumption while minimizing harmful chemical use compared to traditional rayon manufacturing. Choosing Ecovero rayon supports responsible fashion by combining high-quality fabric with greater sustainability and transparency.

Table of Comparison

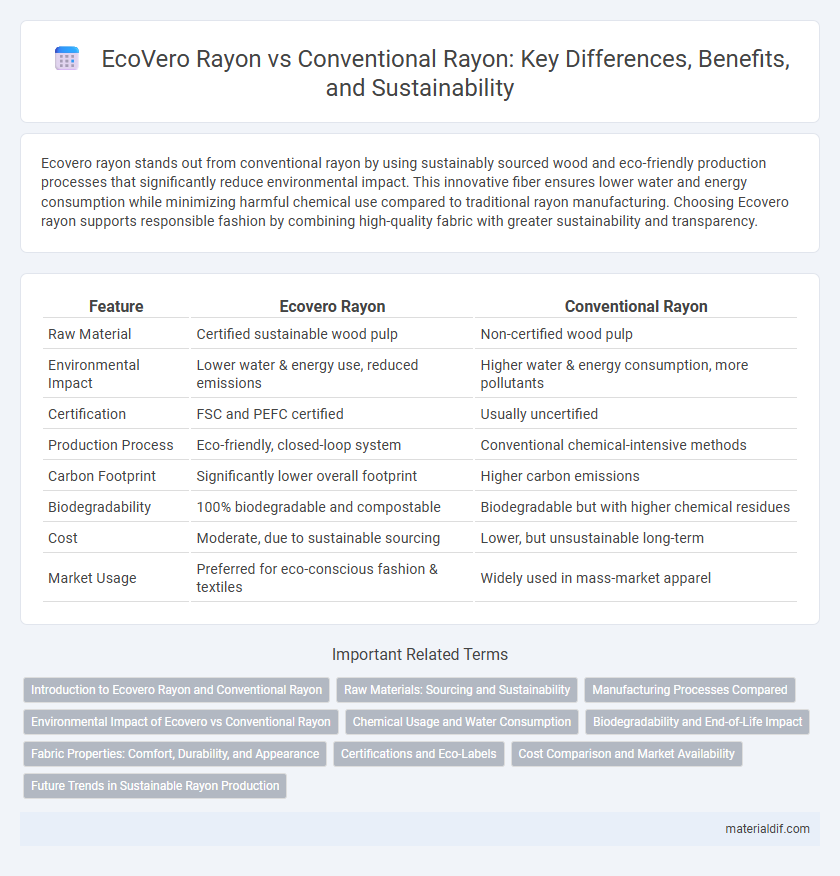

| Feature | Ecovero Rayon | Conventional Rayon |

|---|---|---|

| Raw Material | Certified sustainable wood pulp | Non-certified wood pulp |

| Environmental Impact | Lower water & energy use, reduced emissions | Higher water & energy consumption, more pollutants |

| Certification | FSC and PEFC certified | Usually uncertified |

| Production Process | Eco-friendly, closed-loop system | Conventional chemical-intensive methods |

| Carbon Footprint | Significantly lower overall footprint | Higher carbon emissions |

| Biodegradability | 100% biodegradable and compostable | Biodegradable but with higher chemical residues |

| Cost | Moderate, due to sustainable sourcing | Lower, but unsustainable long-term |

| Market Usage | Preferred for eco-conscious fashion & textiles | Widely used in mass-market apparel |

Introduction to Ecovero Rayon and Conventional Rayon

Ecovero Rayon is a sustainable alternative to conventional rayon, made from certified renewable wood sources and produced under strict environmental standards that reduce water and energy consumption by up to 50%. Conventional rayon, derived from viscose, relies heavily on chemical-intensive processes and non-renewable resources, leading to higher ecological impact and pollution. The introduction of Ecovero Rayon addresses the growing demand for eco-friendly textiles by offering a comparable silky texture with significantly lower carbon emissions and water usage.

Raw Materials: Sourcing and Sustainability

Ecovero rayon is derived from certified sustainable wood sources, primarily sourced from responsibly managed forests with FSC or PEFC certifications, ensuring minimal environmental impact and promoting forest regeneration. Conventional rayon typically relies on wood pulp from unsustainable sources, contributing to deforestation and ecological imbalance. Ecovero's sustainable sourcing practices significantly reduce carbon emissions and water use compared to conventional rayon production.

Manufacturing Processes Compared

Ecovero Rayon is produced using a sustainable manufacturing process that incorporates certified renewable wood sources and utilizes significantly lower water and energy consumption compared to conventional rayon production. The Ecovero process reduces harmful chemical emissions by employing closed-loop technology that recovers solvents, minimizing environmental impact. Conventional rayon manufacturing often involves high water usage, toxic chemicals like sodium hydroxide and carbon disulfide, and lacks comprehensive waste management systems, leading to greater ecological footprint.

Environmental Impact of Ecovero vs Conventional Rayon

Ecovero rayon significantly reduces environmental impact by using certified renewable wood sources and employing a closed-loop production process that recycles water and solvents, minimizing waste and emissions. Conventional rayon production often relies on non-sustainable wood sources, generating high levels of water pollution and chemical waste that contribute to ecosystem degradation. Ecovero's sustainable sourcing and cleaner manufacturing practices make it a more eco-friendly alternative to conventional rayon, supporting reduced carbon footprint and responsible forestry.

Chemical Usage and Water Consumption

Ecovero rayon production utilizes significantly fewer chemicals compared to conventional rayon, employing eco-certified solvents that minimize environmental toxicity. Water consumption in Ecovero rayon manufacturing is reduced by up to 50%, thanks to closed-loop water systems that recycle and treat water efficiently. This sustainable approach results in lower environmental impact and stricter compliance with environmental regulations.

Biodegradability and End-of-Life Impact

Ecovero rayon is produced using sustainable wood sources and renewable technology, leading to enhanced biodegradability compared to conventional rayon derived from chemically intensive processes. Its end-of-life impact is significantly reduced due to lower emissions and faster decomposition in natural environments. This makes Ecovero rayon a more eco-friendly option in textile production, supporting circular economy principles and reducing landfill accumulation.

Fabric Properties: Comfort, Durability, and Appearance

Ecovero rayon offers enhanced comfort due to its breathable and moisture-wicking properties, outperforming conventional rayon in temperature regulation. The durability of Ecovero rayon is superior, thanks to sustainable production methods that ensure fiber strength while minimizing environmental impact. Visually, Ecovero rayon fabrics maintain vibrant colors and a smooth texture longer than conventional rayon, making them a preferred choice for eco-conscious fashion brands.

Certifications and Eco-Labels

Ecovero rayon is certified by FSC (Forest Stewardship Council) and OEKO-TEX Standard 100, ensuring sustainable sourcing and low environmental impact, whereas conventional rayon often lacks such certifications. The Ecovero label guarantees reduced water and energy consumption, with emission cuts up to 50% compared to traditional viscose production. These eco-labels position Ecovero as a more environmentally responsible choice in the textile industry.

Cost Comparison and Market Availability

Ecovero Rayon typically costs 10-20% more than conventional rayon due to its sustainable manufacturing processes and certifications. It is increasingly available in premium textile markets and eco-conscious brands, whereas conventional rayon maintains broader availability and lower prices in mass-market apparel. The cost differential reflects Ecovero's environmental benefits, driving demand despite its relatively limited market penetration.

Future Trends in Sustainable Rayon Production

Ecovero rayon, derived from certified sustainable wood sources, significantly reduces environmental impact compared to conventional rayon, which relies on chemically intensive processes and non-renewable resources. Future trends in sustainable rayon production emphasize closed-loop manufacturing, reducing water and energy consumption while enhancing biodegradability and transparency in supply chains. Innovations such as enzyme-assisted fiber processing and increased adoption of recycled raw materials are poised to drive the transition towards more eco-friendly rayon alternatives.

Ecovero Rayon vs Conventional Rayon Infographic

materialdif.com

materialdif.com