Cupro rayon offers a silk-like texture and superior breathability compared to standard rayon, making it ideal for luxury garment production. Unlike standard rayon, which is derived from wood pulp, cupro is made from regenerated cellulose extracted from cotton linter, resulting in a smoother, more biodegradable fabric. This distinction gives cupro enhanced moisture-wicking properties and a more refined drape, appealing to eco-conscious consumers seeking sustainable fashion options.

Table of Comparison

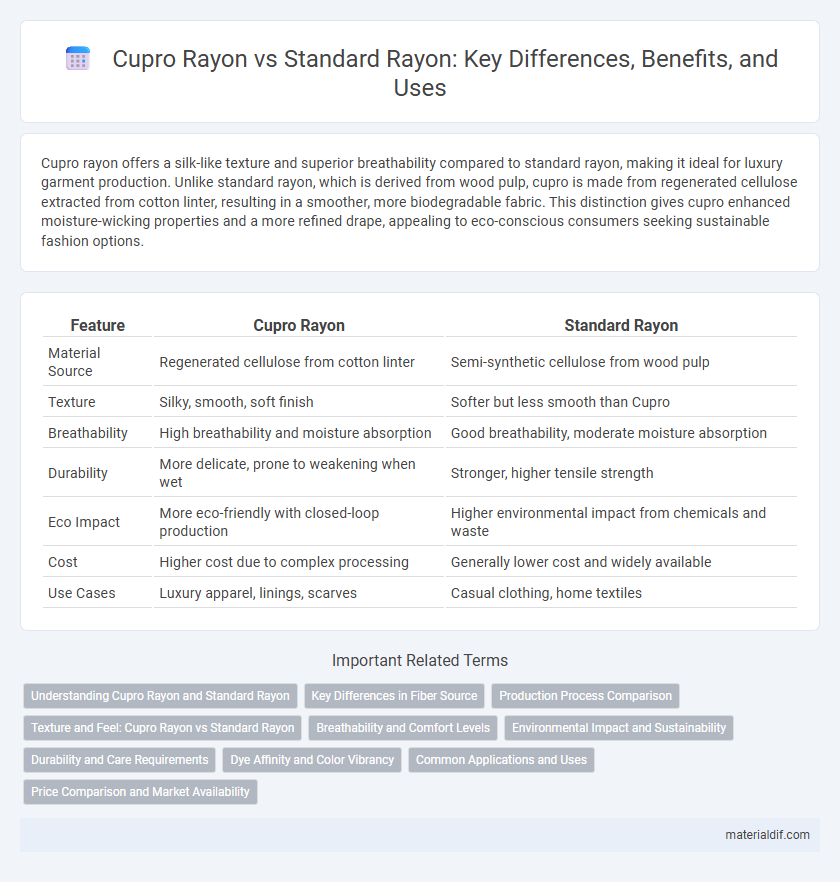

| Feature | Cupro Rayon | Standard Rayon |

|---|---|---|

| Material Source | Regenerated cellulose from cotton linter | Semi-synthetic cellulose from wood pulp |

| Texture | Silky, smooth, soft finish | Softer but less smooth than Cupro |

| Breathability | High breathability and moisture absorption | Good breathability, moderate moisture absorption |

| Durability | More delicate, prone to weakening when wet | Stronger, higher tensile strength |

| Eco Impact | More eco-friendly with closed-loop production | Higher environmental impact from chemicals and waste |

| Cost | Higher cost due to complex processing | Generally lower cost and widely available |

| Use Cases | Luxury apparel, linings, scarves | Casual clothing, home textiles |

Understanding Cupro Rayon and Standard Rayon

Cupro rayon is a regenerated cellulose fiber made from cotton linter, known for its silky texture, breathability, and biodegradability, while standard rayon, often derived from wood pulp, offers versatility but can vary in softness and durability. Cupro rayon undergoes a more refined production process resulting in a smoother, more luxurious fabric compared to standard rayon's broader range of finishes and qualities. Understanding the differences between cupro and standard rayon helps in selecting the right fabric for applications requiring softness, moisture absorption, and sustainability.

Key Differences in Fiber Source

Cupro rayon is derived from cotton linter, the short fibers surrounding cotton seeds, making it a regenerated cellulose fiber with smooth, silk-like texture. Standard rayon, often called viscose, is primarily made from wood pulp, sourced from trees such as beech, pine, or eucalyptus. The differing fiber sources impact the sustainability, texture, and biodegradability of each rayon type, with cupro offering a more refined and breathable fabric.

Production Process Comparison

Cupro rayon is produced using a refined cellulose derived from cotton linter, which undergoes a safer cuprammonium solution process that results in a finer, silk-like fabric. Standard rayon typically utilizes wood pulp processed through the viscose method, involving more chemically intensive steps with carbon disulfide, affecting environmental sustainability. The cuprammonium process of cupro rayon offers a closed-loop system reducing chemical waste compared to the open-loop viscose production of standard rayon.

Texture and Feel: Cupro Rayon vs Standard Rayon

Cupro rayon offers a smoother, silk-like texture compared to the slightly coarse feel of standard rayon. The natural cellulose fibers in cupro create a softer and more breathable fabric that drapes elegantly on the skin. Standard rayon, while lightweight and absorbent, tends to have a more matte finish and less luxurious hand feel than cupro rayon.

Breathability and Comfort Levels

Cupro rayon offers superior breathability compared to standard rayon due to its unique manufacturing process that results in a smoother, more porous fabric structure, allowing enhanced moisture-wicking and air circulation. This increased airflow makes Cupro rayon more comfortable for prolonged wear, especially in warm or humid conditions, as it reduces heat retention and skin irritation. Standard rayon, while breathable, tends to retain more moisture and heat, making it less ideal for comfort during hot weather or active use.

Environmental Impact and Sustainability

Cupro rayon, derived from cotton linter cellulose, features a closed-loop production process that recycles almost 99% of chemicals, significantly reducing environmental pollution compared to standard rayon, which involves more chemically intensive treatments and higher water usage. Sustainable practices in cupro rayon manufacturing lead to lower greenhouse gas emissions and less reliance on non-renewable resources, positioning it as a more eco-friendly alternative to traditional rayon. The biodegradability and natural origin of cupro rayon fibers contribute to reduced landfill waste and enhanced circularity in textile sustainability.

Durability and Care Requirements

Cupro rayon, derived from regenerated cotton fibers, exhibits superior durability compared to standard rayon, making it less prone to wear and tear over time. It requires gentle care, typically hand washing or dry cleaning, to maintain its smooth texture and prevent shrinkage, whereas standard rayon often demands more delicate handling due to its higher susceptibility to stretching and wrinkling. Both fabrics benefit from air drying to preserve their structural integrity, though cupro rayon offers enhanced resilience under frequent use.

Dye Affinity and Color Vibrancy

Cupro Rayon exhibits superior dye affinity compared to standard rayon, resulting in richer and more vibrant color saturation. The filament's finer, smoother fibers allow for more uniform dye absorption, enhancing colorfastness and brightness. Standard rayon, while versatile, often lacks the same intensity and longevity in color vibrancy due to its less refined molecular structure.

Common Applications and Uses

Cupro rayon is primarily used in luxury fashion and high-end linings due to its silk-like texture and superior breathability, making it ideal for delicate garments and accessories. Standard rayon finds widespread application in affordable apparel, upholstery, and home textiles because of its versatility, affordability, and ability to mimic natural fibers like cotton and silk. Both fibers are valued for their moisture absorption and comfort, but Cupro rayon's unique properties cater more to premium textile markets compared to the broader use of standard rayon.

Price Comparison and Market Availability

Cupro rayon, derived from cotton linter, generally commands a higher price than standard rayon due to its complex production process and luxury market positioning. Standard rayon, made from wood pulp, is more widely available and cost-effective, leading to broader market penetration in apparel and home textiles. Market availability of cupro is limited to premium brands and niche suppliers, while standard rayon dominates mass-market textile production globally.

Cupro Rayon vs Standard Rayon Infographic

materialdif.com

materialdif.com