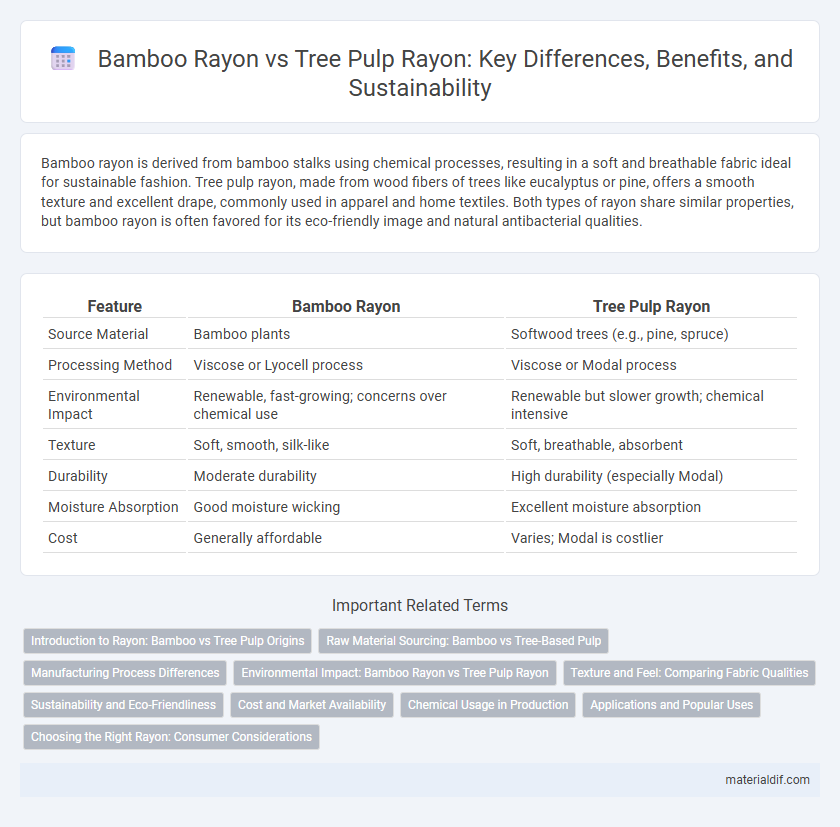

Bamboo rayon is derived from bamboo stalks using chemical processes, resulting in a soft and breathable fabric ideal for sustainable fashion. Tree pulp rayon, made from wood fibers of trees like eucalyptus or pine, offers a smooth texture and excellent drape, commonly used in apparel and home textiles. Both types of rayon share similar properties, but bamboo rayon is often favored for its eco-friendly image and natural antibacterial qualities.

Table of Comparison

| Feature | Bamboo Rayon | Tree Pulp Rayon |

|---|---|---|

| Source Material | Bamboo plants | Softwood trees (e.g., pine, spruce) |

| Processing Method | Viscose or Lyocell process | Viscose or Modal process |

| Environmental Impact | Renewable, fast-growing; concerns over chemical use | Renewable but slower growth; chemical intensive |

| Texture | Soft, smooth, silk-like | Soft, breathable, absorbent |

| Durability | Moderate durability | High durability (especially Modal) |

| Moisture Absorption | Good moisture wicking | Excellent moisture absorption |

| Cost | Generally affordable | Varies; Modal is costlier |

Introduction to Rayon: Bamboo vs Tree Pulp Origins

Bamboo rayon is derived from the cellulose fibers of bamboo grass, known for its rapid growth and eco-friendly cultivation, while tree pulp rayon originates from hardwood trees such as eucalyptus, beech, or pine. Both types undergo chemical processing to convert natural cellulose into regenerated fibers used in textile manufacturing. The sustainable sourcing of bamboo contrasts with the slower growth cycle of trees, influencing environmental impact and material characteristics.

Raw Material Sourcing: Bamboo vs Tree-Based Pulp

Bamboo rayon utilizes bamboo plants as the primary raw material, known for rapid growth and sustainability, allowing for quicker replenishment compared to traditional tree-based sources. Tree pulp rayon derives fibers from hardwood or softwood trees, often involving longer growth cycles and potentially contributing to deforestation concerns. The environmental impact of bamboo rayon is generally lower due to its renewable sourcing, while tree pulp rayon's raw material sourcing depends heavily on responsible forestry management practices.

Manufacturing Process Differences

Bamboo rayon and tree pulp rayon differ mainly in their raw material sourcing and processing methods. Bamboo rayon uses bamboo fibers that undergo chemical treatments like alkaline and carbon disulfide baths to break down cellulose, whereas tree pulp rayon is derived from wood chips subjected to a similar viscose process but often involves different pre-treatment stages based on wood species. The bamboo rayon manufacturing process typically requires more intensive mechanical crushing to extract fibers, influencing the texture and environmental impact compared to traditional tree pulp rayon production.

Environmental Impact: Bamboo Rayon vs Tree Pulp Rayon

Bamboo rayon production often involves chemical treatments that can release harmful toxins and consume significant water resources, similar to tree pulp rayon manufacturing. However, bamboo's rapid growth rate and natural pest resistance may reduce the need for pesticides and deforestation compared to traditional wood sources for tree pulp rayon. Both materials contribute to environmental concerns such as chemical pollution and energy consumption, emphasizing the need for sustainable processing improvements.

Texture and Feel: Comparing Fabric Qualities

Bamboo rayon fabric offers a silky-smooth texture with a naturally soft and breathable feel, making it ideal for sensitive skin and lightweight garments. Tree pulp rayon, often derived from hardwoods like beech or eucalyptus, tends to have a slightly coarser texture but provides greater durability and structure in textiles. Both fabrics exhibit excellent moisture-wicking properties, yet bamboo rayon is typically favored for its luxurious softness and eco-friendly appeal.

Sustainability and Eco-Friendliness

Bamboo rayon is often marketed as a sustainable fabric due to bamboo's rapid growth and minimal pesticide requirements, but the chemical-intensive production process can negate some eco-friendly benefits. Tree pulp rayon, typically derived from managed forests, relies on certified sustainable forestry practices like FSC certification to ensure responsible sourcing and reduced environmental impact. Both types of rayon involve viscose processing, which has ecological challenges, but advancements in closed-loop production systems are improving sustainability for both bamboo and tree pulp rayon.

Cost and Market Availability

Bamboo rayon generally costs more than tree pulp rayon due to the additional processing required to break down bamboo fibers. Tree pulp rayon dominates the market with greater availability and lower production costs, making it a preferred choice for mass-market textiles. Bamboo rayon remains niche, often marketed for its eco-friendly appeal despite limited large-scale manufacturing infrastructure.

Chemical Usage in Production

Bamboo rayon production involves extensive chemical processing, including the use of sodium hydroxide and carbon disulfide to break down bamboo cellulose into viscose, similar to traditional tree pulp rayon methods. Tree pulp rayon uses wood fibers from trees like pine or eucalyptus, requiring comparable chemical treatments to convert cellulose into rayon fibers. Both processes raise environmental concerns due to the release of hazardous chemicals, but bamboo rayon's rapid growth rate may offer a more sustainable raw material source despite equivalent chemical usage.

Applications and Popular Uses

Bamboo rayon is widely used in eco-friendly textiles, offering softness and moisture-wicking properties ideal for activewear, baby clothes, and bedding. Tree pulp rayon, derived primarily from hardwoods like beech and eucalyptus, is favored for clothing, upholstery, and industrial fabrics due to its versatility and durability. Both types serve diverse applications, but bamboo rayon is particularly popular in sustainable fashion markets, while tree pulp rayon dominates in conventional textile industries.

Choosing the Right Rayon: Consumer Considerations

Bamboo rayon offers enhanced softness and natural antimicrobial properties, making it ideal for sensitive skin, while tree pulp rayon is often more affordable and widely available. Consumers should consider factors such as environmental impact, durability, and intended use when selecting the right rayon type. Evaluating certifications like FSC or OEKO-TEX can further ensure sustainable and safe fabric choices.

Bamboo Rayon vs Tree Pulp Rayon Infographic

materialdif.com

materialdif.com