High Wet Modulus (HWM) Rayon offers superior strength and dimensional stability when wet compared to Regular Rayon, making it ideal for applications requiring durability and resistance to shrinkage. Its enhanced wet strength is achieved through a more controlled molecular orientation process during manufacturing, resulting in fibers that maintain integrity under moisture exposure. HWM Rayon is preferred in textiles and industrial uses where performance under wet conditions is critical, outperforming Regular Rayon's tendency to weaken and deform.

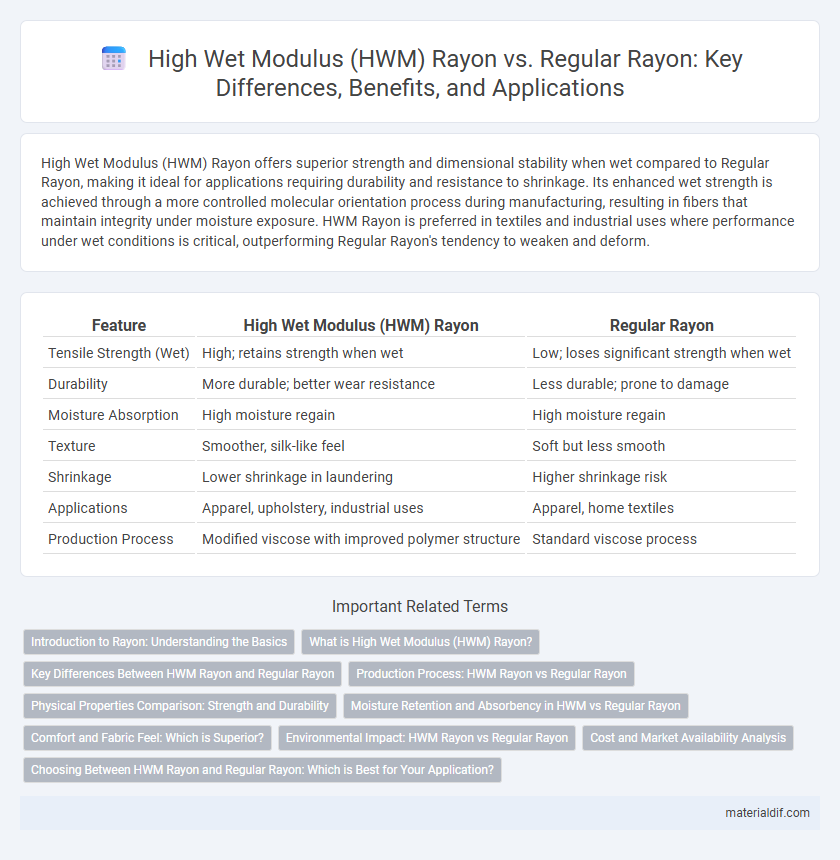

Table of Comparison

| Feature | High Wet Modulus (HWM) Rayon | Regular Rayon |

|---|---|---|

| Tensile Strength (Wet) | High; retains strength when wet | Low; loses significant strength when wet |

| Durability | More durable; better wear resistance | Less durable; prone to damage |

| Moisture Absorption | High moisture regain | High moisture regain |

| Texture | Smoother, silk-like feel | Soft but less smooth |

| Shrinkage | Lower shrinkage in laundering | Higher shrinkage risk |

| Applications | Apparel, upholstery, industrial uses | Apparel, home textiles |

| Production Process | Modified viscose with improved polymer structure | Standard viscose process |

Introduction to Rayon: Understanding the Basics

Rayon is a versatile semi-synthetic fiber made from regenerated cellulose, primarily derived from wood pulp. High Wet Modulus (HWM) Rayon, also known as modal, differs from regular rayon by offering greater strength and dimensional stability when wet due to enhanced molecular orientation during production. This improved wet strength makes HWM Rayon ideal for applications requiring durability and resilience, such as activewear and home textiles.

What is High Wet Modulus (HWM) Rayon?

High Wet Modulus (HWM) Rayon is a type of rayon fiber engineered to have significantly higher tensile strength and dimensional stability when wet, compared to regular rayon. This durability is achieved through a modified viscose process that enhances the fiber's molecular orientation and crystallinity, making HWM rayon ideal for applications requiring moisture exposure or rigorous mechanical stress. Due to its superior wet strength, HWM rayon is widely used in textile products like apparel and industrial fabrics where enhanced durability and longevity are critical.

Key Differences Between HWM Rayon and Regular Rayon

High Wet Modulus (HWM) Rayon exhibits enhanced tensile strength and dimensional stability when wet, unlike Regular Rayon which tends to weaken and lose shape under moisture. HWM Rayon achieves this through advanced chemical processing that realigns and strengthens cellulose fibers, resulting in fabric that is more durable and resistant to shrinkage. The key differences lie in HWM Rayon's superior wet strength, improved abrasion resistance, and higher resilience, making it ideal for applications requiring consistent performance in humid conditions.

Production Process: HWM Rayon vs Regular Rayon

High Wet Modulus (HWM) rayon is produced through a modified viscose process that incorporates aldehyde cross-linking agents, enhancing fiber strength and elasticity in wet conditions compared to regular rayon. Regular rayon undergoes a conventional viscose method involving cellulose xanthate regeneration, resulting in fibers with lower wet strength and greater tendency to shrink or deform when wet. The advanced production technique of HWM rayon yields fibers with superior dimensional stability and durability, making it preferable for applications requiring enhanced wet performance.

Physical Properties Comparison: Strength and Durability

High Wet Modulus (HWM) Rayon exhibits significantly higher tensile strength and enhanced durability compared to regular rayon, maintaining up to 50% more strength when wet. The molecular structure of HWM rayon is more oriented and crystalline, resulting in improved resistance to physical wear and mechanical stress during use. These enhanced physical properties make HWM rayon ideal for textile applications demanding superior performance and longevity.

Moisture Retention and Absorbency in HWM vs Regular Rayon

High Wet Modulus (HWM) Rayon exhibits significantly enhanced moisture retention and absorbency compared to regular rayon, making it more effective in applications requiring superior water uptake. The increased wet modulus in HWM rayon results from a higher degree of polymer orientation and crystallinity, which improves its structural integrity when wet and boosts its moisture absorption capacity. This characteristic allows HWM rayon to maintain strength and durability in moist environments, unlike regular rayon, which tends to weaken and lose absorbency under similar conditions.

Comfort and Fabric Feel: Which is Superior?

High Wet Modulus (HWM) Rayon offers a superior fabric feel compared to regular rayon, characterized by increased strength, durability, and a silkier texture that enhances comfort. HWM rayon retains its smoothness and shape even when wet, reducing fabric sagging and improving wearability in humid conditions. Regular rayon tends to feel softer initially, but it loses tensile strength and comfort when damp, making HWM rayon the preferred choice for long-lasting comfort and a stable fabric feel.

Environmental Impact: HWM Rayon vs Regular Rayon

High Wet Modulus (HWM) Rayon demonstrates a lower environmental impact compared to Regular Rayon due to its enhanced fiber strength, which reduces fabric weight and resource consumption during production. HWM Rayon requires less chemical treatment and energy input, contributing to a more sustainable manufacturing process. Additionally, the improved durability of HWM Rayon products extends their lifecycle, minimizing waste and promoting eco-friendly textile use.

Cost and Market Availability Analysis

High Wet Modulus (HWM) Rayon commands a higher market price due to its enhanced tensile strength and superior durability in wet conditions, making it a premium choice for performance textiles. Regular Rayon remains more widely available and cost-effective, benefiting from established manufacturing processes and larger-scale production. Market availability for HWM Rayon is comparatively limited, primarily serving specialized applications where its performance advantages justify the additional cost.

Choosing Between HWM Rayon and Regular Rayon: Which is Best for Your Application?

High Wet Modulus (HWM) Rayon offers superior strength and durability compared to regular rayon, making it ideal for applications requiring enhanced wet performance, such as high-quality textiles and industrial uses. Regular rayon, while softer and more cost-effective, is best suited for everyday garments and products where comfort and affordability are priorities. Selecting between HWM rayon and regular rayon depends on balancing performance needs against budget constraints and specific end-use requirements.

High Wet Modulus (HWM) Rayon vs Regular Rayon Infographic

materialdif.com

materialdif.com