Rayon pet offers exceptional drapability, creating fluid, graceful movement in garments that enhance comfort and style. Its softness allows fabric to contour naturally, contrasting with stiffer materials that maintain rigid shapes and restrict flow. Choosing rayon pet fabric ensures a lightweight, flexible feel while balancing structure for versatile apparel designs.

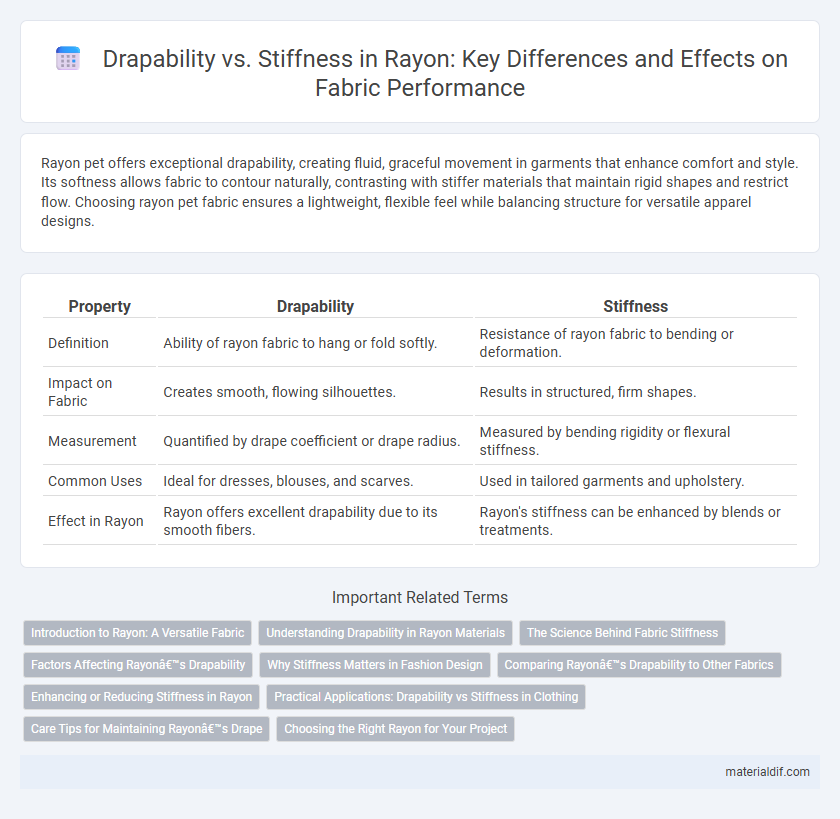

Table of Comparison

| Property | Drapability | Stiffness |

|---|---|---|

| Definition | Ability of rayon fabric to hang or fold softly. | Resistance of rayon fabric to bending or deformation. |

| Impact on Fabric | Creates smooth, flowing silhouettes. | Results in structured, firm shapes. |

| Measurement | Quantified by drape coefficient or drape radius. | Measured by bending rigidity or flexural stiffness. |

| Common Uses | Ideal for dresses, blouses, and scarves. | Used in tailored garments and upholstery. |

| Effect in Rayon | Rayon offers excellent drapability due to its smooth fibers. | Rayon's stiffness can be enhanced by blends or treatments. |

Introduction to Rayon: A Versatile Fabric

Rayon exhibits exceptional drapability due to its smooth texture and flexibility, making it ideal for flowing garments and soft furnishings. Its moderate stiffness can be adjusted through various finishing techniques, allowing designers to tailor the fabric's hand feel and silhouette. This balance between drapability and stiffness makes rayon a versatile fabric choice in both fashion and interior applications.

Understanding Drapability in Rayon Materials

Drapability in rayon materials refers to the fabric's ability to conform smoothly and fluidly over a form, influenced by fiber length, yarn twist, and fabric construction. Unlike stiffness, which resists bending and folding, rayon's inherent softness, moisture absorbency, and smooth surface enhance its drape quality, making it ideal for flowing garments and delicate designs. Evaluating the balance between drapability and stiffness involves assessing tensile strength and flexural rigidity to optimize fabric performance in fashion applications.

The Science Behind Fabric Stiffness

Fabric stiffness in rayon is governed by the molecular arrangement and fiber cross-linking, which impact its drapability and flexibility. Rayon fibers with higher crystallinity exhibit greater stiffness due to limited molecular mobility, resulting in reduced drape and a more structured appearance. Understanding the interplay between polymer chain orientation and intermolecular forces enables optimization of rayon fabric properties for desired stiffness and draping effects.

Factors Affecting Rayon’s Drapability

Rayon's drapability is influenced primarily by fiber length, yarn twist, and fabric weave, which determine the material's flexibility and fluidity. The fiber's moisture absorption capacity enhances softness, allowing the fabric to conform smoothly over contours, while chemical treatments during finishing can alter stiffness, impacting ease of movement and aesthetic appeal. Temperature and humidity also affect rayon's drape by modifying fiber swelling and pliability, making environmental conditions key factors in garment design.

Why Stiffness Matters in Fashion Design

Stiffness in rayon fabric directly affects garment structure, influencing how designs maintain their intended shape and form throughout wear. High stiffness enhances drapability control, allowing designers to create bold silhouettes and emphasize architectural lines in fashion collections. Understanding stiffness helps balance softness and support, crucial for achieving both comfort and visual impact in apparel.

Comparing Rayon’s Drapability to Other Fabrics

Rayon exhibits superior drapability compared to stiffer fabrics like denim and canvas, allowing it to flow and contour gracefully around the body. Its smooth texture and lightweight properties enhance fluid movement, making it ideal for garments requiring elegant folds and softness. Unlike polyester or cotton blends that often prioritize rigidity, rayon provides a balanced flexibility, offering both comfort and a flattering silhouette.

Enhancing or Reducing Stiffness in Rayon

Enhancing stiffness in rayon can be achieved through chemical treatments or blending with synthetic fibers, improving its structural integrity for applications like upholstery and outerwear. Reducing stiffness involves optimizing fiber processing methods, such as modifying the degree of polymerization or using finishing agents, to maintain rayon's characteristic softness and drapability. Balancing these factors allows manufacturers to tailor rayon's texture and flexibility, meeting diverse textile needs from flowy garments to durable fabrics.

Practical Applications: Drapability vs Stiffness in Clothing

Rayon's exceptional drapability makes it ideal for flowing garments like dresses and blouses, providing a smooth, elegant silhouette that moves with the body. Its moderate stiffness allows for structured designs such as tailored shirts and skirts without compromising comfort or flexibility. This balance between drapability and stiffness enables versatile applications in both casual and formal clothing, enhancing wearability and style.

Care Tips for Maintaining Rayon’s Drape

Maintaining rayon's drapability requires gentle care to preserve its lightweight and fluid texture while avoiding stiffness. Hand washing in cold water with mild detergent and air drying on a flat surface helps prevent fabric distortion and maintains the soft drape. Avoid wringing and exposure to direct sunlight to reduce fiber damage and stiffness in rayon garments.

Choosing the Right Rayon for Your Project

Rayon offers varying levels of drapability and stiffness, making it essential to select the appropriate type for your project. High-viscosity rayon demonstrates excellent drapability, ideal for flowing garments, while high-wet-modulus (HWM) rayon provides greater stiffness suitable for structured designs. Balancing these properties ensures optimal fabric performance and aesthetic appeal in your finished piece.

Drapability vs Stiffness Infographic

materialdif.com

materialdif.com