Rayon filament fibers are continuous strands that provide superior strength, smoothness, and lustrous appearance, making them ideal for high-quality textiles and upholstery. In contrast, rayon staple fibers consist of shorter lengths, offering greater flexibility and softness, which are preferred for blended fabrics and apparel due to their enhanced breathability and comfort. Understanding the distinct properties of rayon filament versus rayon staple fiber allows for optimal selection in manufacturing processes tailored to specific performance and aesthetic requirements.

Table of Comparison

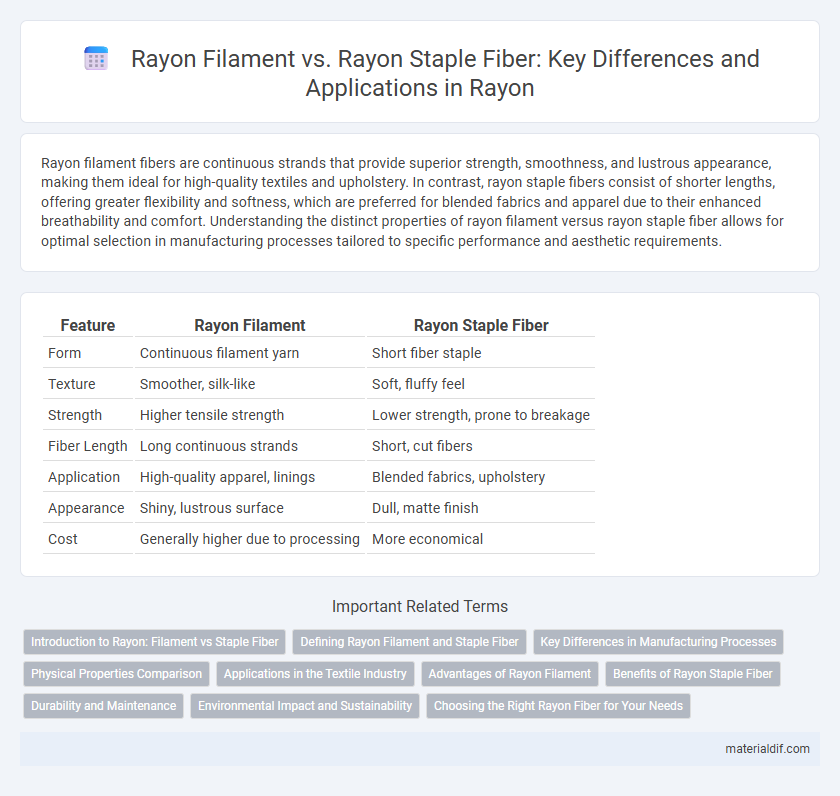

| Feature | Rayon Filament | Rayon Staple Fiber |

|---|---|---|

| Form | Continuous filament yarn | Short fiber staple |

| Texture | Smoother, silk-like | Soft, fluffy feel |

| Strength | Higher tensile strength | Lower strength, prone to breakage |

| Fiber Length | Long continuous strands | Short, cut fibers |

| Application | High-quality apparel, linings | Blended fabrics, upholstery |

| Appearance | Shiny, lustrous surface | Dull, matte finish |

| Cost | Generally higher due to processing | More economical |

Introduction to Rayon: Filament vs Staple Fiber

Rayon is a versatile regenerated cellulose fiber derived from wood pulp, available primarily in two forms: filament and staple fiber. Rayon filament consists of continuous, smooth fibers ideal for creating lustrous fabrics with a silk-like appearance, while rayon staple fibers are shorter, resembling natural cotton or wool fibers, commonly used in blends for softness and breathability. Understanding the differences in fiber length and texture between rayon filament and staple fiber is essential for selecting the appropriate application in textiles.

Defining Rayon Filament and Staple Fiber

Rayon filament consists of continuous fibers that are long, smooth, and uniform, ideal for producing fine, lustrous fabrics with a silky texture. In contrast, rayon staple fiber comprises shorter, cut fibers that resemble natural cotton, enabling versatility in textile applications such as blending and knitting. Filament rayon offers strength and sheen, while staple rayon provides softness and adaptability for various fabric types.

Key Differences in Manufacturing Processes

Rayon filament is produced through a continuous spinning process, creating long, smooth fibers ideal for high-quality textiles and lustrous finishes. In contrast, rayon staple fiber involves cutting regenerated cellulose fibers into short lengths, resembling natural cotton fibers that are spun into yarns for softer, textured fabrics. The manufacturing difference lies in filament rayon's extrusion into continuous filaments, whereas staple rayon undergoes fiber cutting and carding to produce staple materials.

Physical Properties Comparison

Rayon filament fibers exhibit higher tensile strength and smoother surface texture compared to rayon staple fibers, resulting in enhanced durability and luster in finished textiles. Rayon staple fibers possess shorter lengths and increased fiber ends, leading to a softer hand feel but reduced strength and a tendency to pill. The physical differences influence fabric performance, with filament yarns favored for robust, lustrous products and staple fibers preferred for softer, breathable fabrics.

Applications in the Textile Industry

Rayon filament yarns, characterized by continuous fibers, are widely used in high-quality textiles such as lingerie, linings, and maxi dresses due to their smooth texture and luster. Rayon staple fibers, composed of shorter fibers spun together, are commonly utilized in blended fabrics for apparel, home textiles, and upholstery, offering enhanced breathability and comfort. The choice between rayon filament and staple fiber depends on the desired fabric properties, with filament yarns providing strength and sheen, while staple fibers contribute softness and versatility in textile applications.

Advantages of Rayon Filament

Rayon filament offers superior strength and smoothness compared to rayon staple fiber, making it ideal for producing high-quality textiles with a luxurious feel. Its continuous long fibers result in less pilling and enhanced durability, which improves fabric longevity and maintains appearance after multiple washes. Rayon filament also provides better uniformity and a silk-like sheen, enhancing the aesthetic appeal of garments and home textiles.

Benefits of Rayon Staple Fiber

Rayon staple fiber offers superior versatility and ease of blending with natural and synthetic fibers compared to rayon filament, enhancing fabric texture and durability. Its shorter fiber length provides better moisture absorption and breathability, making it ideal for comfortable, soft textiles used in apparel and home furnishings. The cost-effective production of rayon staple fiber supports sustainable manufacturing processes while delivering high-quality, eco-friendly fabrics.

Durability and Maintenance

Rayon filament fibers exhibit superior durability compared to rayon staple fibers due to their continuous filament structure, which provides enhanced tensile strength and resistance to abrasion. Maintenance of rayon filament fabrics is generally easier, as they resist pilling and maintain dimensional stability better during washing. Conversely, rayon staple fibers tend to be more prone to wear and require gentler care to prevent fiber breakage and shrinkage.

Environmental Impact and Sustainability

Rayon filament and rayon staple fiber differ significantly in environmental impact and sustainability, with filament yarns typically requiring less water and energy during production due to continuous processing methods. Staple fiber production involves more mechanical steps and generates higher waste and emissions, raising sustainability concerns. Choosing filament rayon can reduce ecological footprints, promoting lower resource consumption and better waste management in textile manufacturing.

Choosing the Right Rayon Fiber for Your Needs

Rayon filament offers a smooth, continuous strand ideal for high-quality textiles requiring strength and luster, while rayon staple fiber consists of shorter fibers perfect for blending and creating soft, fluffy fabrics. Selecting the right rayon fiber depends on the end product's texture, durability, and appearance requirements, with filament suited for sleek, durable yarns and staple fiber favored for comfort and versatility. Consider application-specific factors such as fabric weight, breathability, and blending compatibility to optimize performance and aesthetics.

Rayon Filament vs Rayon Staple Fiber Infographic

materialdif.com

materialdif.com