Rayon production involves a chemically intensive process where cellulose is dissolved in toxic solvents, generating significant environmental pollutants and requiring extensive water treatment. Lyocell production uses a more eco-friendly closed-loop system with non-toxic solvents, allowing for solvent recovery and reduced emissions. This cleaner production method makes Lyocell a sustainable alternative to traditional Rayon.

Table of Comparison

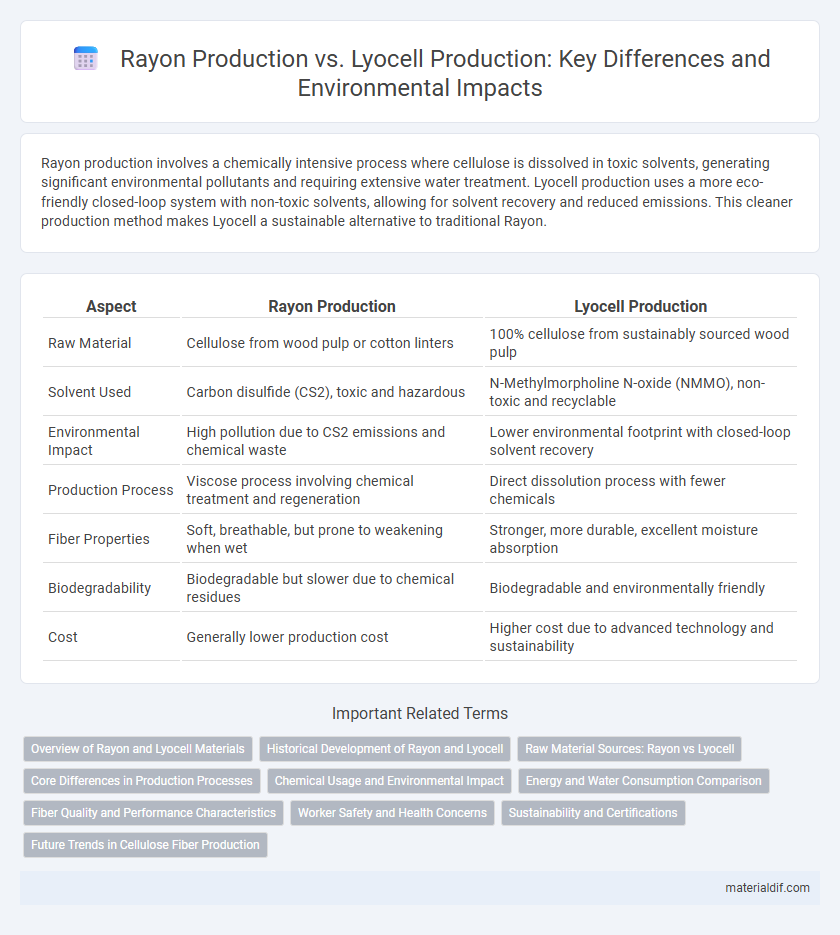

| Aspect | Rayon Production | Lyocell Production |

|---|---|---|

| Raw Material | Cellulose from wood pulp or cotton linters | 100% cellulose from sustainably sourced wood pulp |

| Solvent Used | Carbon disulfide (CS2), toxic and hazardous | N-Methylmorpholine N-oxide (NMMO), non-toxic and recyclable |

| Environmental Impact | High pollution due to CS2 emissions and chemical waste | Lower environmental footprint with closed-loop solvent recovery |

| Production Process | Viscose process involving chemical treatment and regeneration | Direct dissolution process with fewer chemicals |

| Fiber Properties | Soft, breathable, but prone to weakening when wet | Stronger, more durable, excellent moisture absorption |

| Biodegradability | Biodegradable but slower due to chemical residues | Biodegradable and environmentally friendly |

| Cost | Generally lower production cost | Higher cost due to advanced technology and sustainability |

Overview of Rayon and Lyocell Materials

Rayon is a semi-synthetic fiber made from regenerated cellulose derived primarily from wood pulp, offering a versatile and cost-effective fabric option. Lyocell, a subtype of rayon, is produced using a closed-loop process that recycles nearly all solvents, resulting in a more environmentally friendly fabric with superior moisture management and durability. Both materials share cellulose origins but differ significantly in production methods, sustainability profiles, and performance characteristics.

Historical Development of Rayon and Lyocell

Rayon production began in the early 20th century as a semi-synthetic fiber derived from cellulose, revolutionizing the textile industry by providing an affordable alternative to silk. Lyocell production emerged later in the late 20th century as an eco-friendly innovation, utilizing a closed-loop process that reduces chemical waste compared to traditional viscose rayon methods. The historical development of rayon set the foundation for lyocell, which improved sustainability and performance while maintaining the cellulose-based fiber's versatility.

Raw Material Sources: Rayon vs Lyocell

Rayon production primarily relies on cellulose extracted from wood pulp, often sourced from hardwood trees such as beech, pine, and eucalyptus, while lyocell production uses sustainably harvested eucalyptus, oak, and birch wood, emphasizing renewable and eco-friendly forestry practices. The raw material for rayon involves chemically intensive processes to transform cellulose into fibers, resulting in environmental concerns related to chemical use and pollution. In contrast, lyocell production employs a closed-loop process that recycles solvents and minimizes waste, making its raw material sourcing and processing more sustainable compared to traditional rayon.

Core Differences in Production Processes

Rayon production involves chemically converting cellulose from wood pulp into a viscous solution through the viscose process, which includes steps like steeping, pressing, and xanthation, resulting in significant use of sodium hydroxide and carbon disulfide. Lyocell production utilizes a more environmentally friendly method by dissolving cellulose in a non-toxic amine oxide solvent without derivatization, allowing direct fiber formation with minimal chemical waste. Key differences lie in rayon's multistep chemical transformations and higher toxic emissions, contrasted with lyocell's closed-loop process and reduced environmental impact.

Chemical Usage and Environmental Impact

Rayon production relies heavily on chemicals like carbon disulfide and sulfuric acid, leading to significant air and water pollution risks, while lyocell uses non-toxic solvents in a closed-loop process that recycles 99% of chemicals, minimizing environmental impact. The chemical-intensive nature of rayon contributes to higher emissions and hazardous waste, contrasting with lyocell's more sustainable manufacturing approach. Lyocell's eco-friendly production reduces water usage and toxic effluents, positioning it as a greener alternative to conventional rayon fibers.

Energy and Water Consumption Comparison

Rayon production typically consumes higher amounts of energy and water compared to lyocell production due to its chemical-intensive processes and multiple washing stages. Lyocell manufacturing uses a closed-loop system that recycles solvents and reduces water use by up to 50%, and its energy consumption is lower because of more efficient machinery. Studies indicate that lyocell's sustainable production methods result in 30-40% less water usage and 20-30% reduced energy demand relative to traditional rayon production.

Fiber Quality and Performance Characteristics

Rayon production involves a viscose process that results in fibers with moderate strength, high absorbency, and a smooth texture, making it suitable for lightweight, breathable fabrics but prone to shrinking and losing durability when wet. Lyocell production uses a solvent-spinning process yielding fibers with superior tensile strength, excellent moisture-wicking properties, and enhanced wrinkle resistance, offering greater durability and comfort in performance textiles. The environmental impact of lyocell production is also lower, generating less toxic waste compared to traditional rayon, making it a preferred choice for sustainable fiber performance.

Worker Safety and Health Concerns

Rayon production involves hazardous chemicals such as carbon disulfide, posing significant risks to worker health, including neurological and respiratory issues. Lyocell production uses a closed-loop process with non-toxic solvents like N-methylmorpholine N-oxide, reducing chemical exposure and improving workplace safety. The enhanced environmental controls in lyocell manufacturing contribute to a safer work environment compared to traditional rayon production.

Sustainability and Certifications

Rayon production often involves hazardous chemicals such as carbon disulfide, leading to significant environmental concerns, whereas lyocell production uses a closed-loop process that recycles 99% of its solvents, enhancing its sustainability profile. Lyocell typically holds certifications like OEKO-TEX(r), FSC(r), and EU Ecolabel, reflecting its commitment to eco-friendly practices, while rayon certifications are less consistently available and often vary by manufacturer. The sustainable production methods of lyocell result in lower water usage, reduced emissions, and less chemical waste compared to traditional rayon.

Future Trends in Cellulose Fiber Production

Rayon production is expected to experience slower growth due to environmental concerns and higher chemical usage, while lyocell production is rapidly increasing because of its eco-friendly closed-loop manufacturing process and superior biodegradability. Innovations in solvent recovery and sustainable raw material sourcing are driving lyocell's prominence in the cellulose fiber market. Future trends highlight a strong shift toward lyocell as manufacturers prioritize reduced environmental impact and enhanced fiber performance.

Rayon Production vs Lyocell Production Infographic

materialdif.com

materialdif.com