Ring-spun rayon fibers are created by continuously twisting and thinning the fiber strands, resulting in a softer, stronger, and more durable fabric compared to open-end spun rayon, which is produced by chopping and spinning shorter fibers that yield a coarser texture. Ring-spun rayon provides superior smoothness and a finer hand feel, making it ideal for high-quality textiles and apparel. Open-end spun rayon, though more economical, is less uniform and tends to have a rougher surface with lower tensile strength.

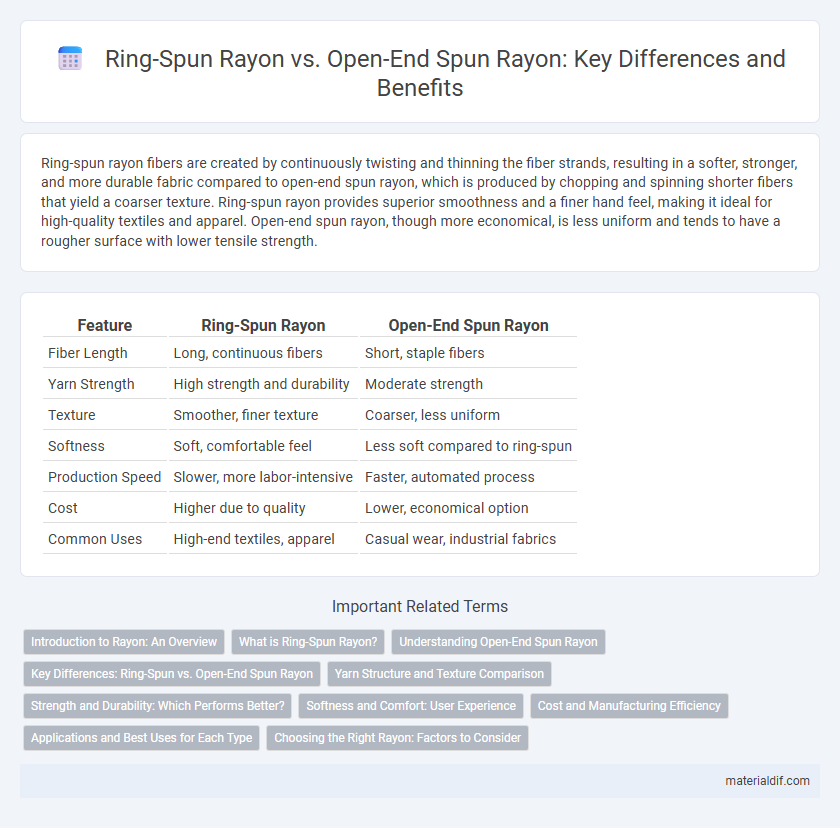

Table of Comparison

| Feature | Ring-Spun Rayon | Open-End Spun Rayon |

|---|---|---|

| Fiber Length | Long, continuous fibers | Short, staple fibers |

| Yarn Strength | High strength and durability | Moderate strength |

| Texture | Smoother, finer texture | Coarser, less uniform |

| Softness | Soft, comfortable feel | Less soft compared to ring-spun |

| Production Speed | Slower, more labor-intensive | Faster, automated process |

| Cost | Higher due to quality | Lower, economical option |

| Common Uses | High-end textiles, apparel | Casual wear, industrial fabrics |

Introduction to Rayon: An Overview

Rayon is a versatile semi-synthetic fiber derived from cellulose, widely used in textiles for its softness and breathability. Ring-spun rayon involves twisting fibers tightly to produce finer, stronger yarns ideal for high-quality fabrics, while open-end spun rayon uses a faster, less complex process yielding coarser, more economical yarns suitable for bulkier textiles. Understanding the distinctions between these spinning methods highlights rayon's adaptability in various fabric applications, balancing durability and cost-effectiveness.

What is Ring-Spun Rayon?

Ring-spun rayon is a type of rayon yarn produced using the ring-spinning technique, which involves continuously twisting and thinning the fibers to create a finer and stronger yarn compared to open-end spun rayon. This process results in a smoother texture, increased durability, and enhanced softness, making ring-spun rayon ideal for high-quality fabrics used in garments and upholstery. The tightly spun fibers also improve the fabric's tensile strength and reduce pilling, distinguishing it from the coarser, bulkier open-end spun rayon.

Understanding Open-End Spun Rayon

Open-end spun rayon is produced by feeding fibers into a rotor that twists them into yarn, resulting in a coarser texture and less uniformity compared to ring-spun rayon. This method enhances production speed and reduces labor costs, making it ideal for mass-market textile applications. Open-end spun rayon fibers generally have lower tensile strength but offer increased bulk and breathability, suitable for casual wear and home textiles.

Key Differences: Ring-Spun vs. Open-End Spun Rayon

Ring-spun rayon fibers are produced by twisting and thinning the fiber strands to create a finer, stronger yarn with a smoother texture, making them ideal for high-quality fabrics that require durability and softness. Open-end spun rayon, on the other hand, is manufactured by directly feeding fibers into the rotor to create coarser, bulkier yarns that result in a rougher texture and lower strength but higher production speed and cost efficiency. Key differences include the fiber alignment and manufacturing process, which affect the yarn's strength, texture, uniformity, and suitability for various textile applications.

Yarn Structure and Texture Comparison

Ring-spun rayon yarn features a tightly twisted structure with long, continuous filaments that produce a smooth, fine texture and enhanced strength, ideal for high-quality fabrics. Open-end spun rayon yarn is characterized by shorter, coarser fibers with a more uneven surface, resulting in a bulkier texture and lower tensile strength suitable for casual, durable garments. The structural differences directly influence fabric softness, durability, and appearance, making ring-spun rayon preferable for luxurious textiles while open-end spun rayon suits utility-focused applications.

Strength and Durability: Which Performs Better?

Ring-spun rayon fibers exhibit superior strength and durability compared to open-end spun rayon due to their longer, tightly twisted fibers that create a denser yarn structure. Open-end spun rayon, while more cost-effective and faster to produce, tends to have weaker tensile strength and reduced abrasion resistance because of its shorter staple fibers and looser formation. Therefore, fabrics made from ring-spun rayon are better suited for applications requiring enhanced performance and longevity.

Softness and Comfort: User Experience

Ring-spun rayon fibers are finer and more tightly twisted, resulting in fabric that offers superior softness and a smoother texture against the skin compared to open-end spun rayon. Open-end spun rayon tends to produce bulkier yarns with a rougher surface, which can affect the overall comfort, making garments less soft and breathable. Users often prefer ring-spun rayon clothing for its enhanced softness and comfortable drape, particularly in close-to-skin apparel like t-shirts and undergarments.

Cost and Manufacturing Efficiency

Ring-spun rayon fibers exhibit higher manufacturing costs due to their intricate spinning process, which involves twisting fibers for enhanced strength and smoothness. Open-end spun rayon offers greater manufacturing efficiency by utilizing a faster, less labor-intensive production method, significantly reducing overall costs. Businesses often prefer open-end spun rayon for cost-effective large-scale textile production without compromising basic fabric quality.

Applications and Best Uses for Each Type

Ring-spun rayon offers superior strength, softness, and durability, making it ideal for high-quality apparel, luxury bedding, and fine textiles requiring a smooth finish and long-lasting wear. Open-end spun rayon provides a more cost-effective option with a coarser texture, best suited for casual wear, industrial fabric applications, and items where affordability and bulk production are prioritized. Choosing between ring-spun and open-end spun rayon depends on the desired balance between fabric quality, texture, and production budget.

Choosing the Right Rayon: Factors to Consider

Choosing the right rayon involves evaluating the differences between ring-spun and open-end spun rayon, particularly in terms of fiber strength and fabric texture. Ring-spun rayon offers finer yarns with enhanced softness and durability, making it ideal for high-quality garments. In contrast, open-end spun rayon tends to produce coarser yarns with a more textured finish, often preferred for casual or utility fabrics where cost-effectiveness is prioritized.

Ring-spun rayon vs Open-end spun rayon Infographic

materialdif.com

materialdif.com