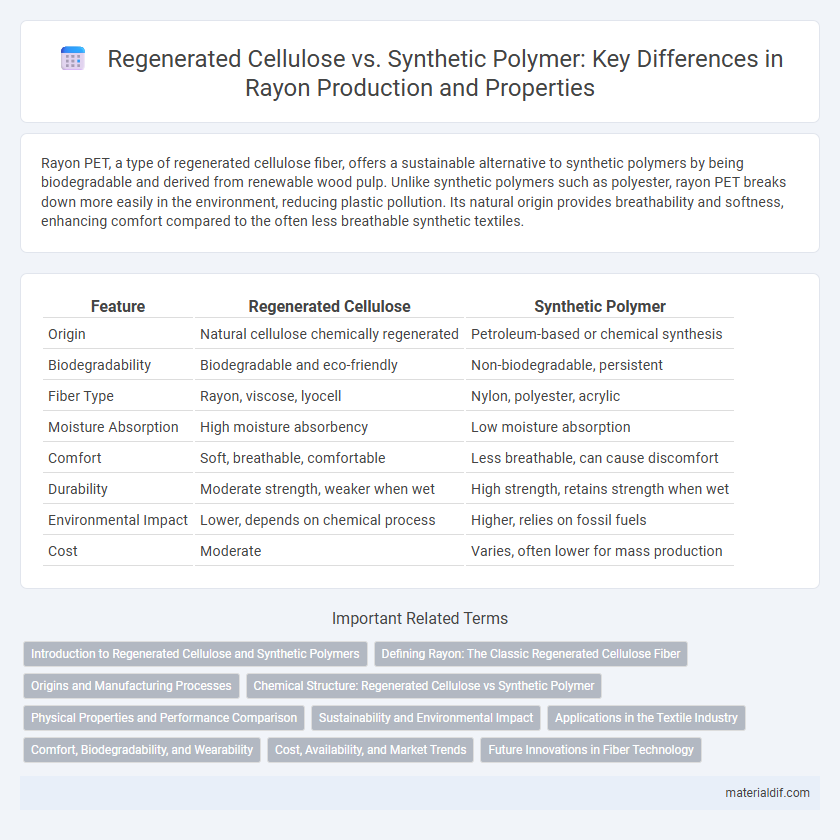

Rayon PET, a type of regenerated cellulose fiber, offers a sustainable alternative to synthetic polymers by being biodegradable and derived from renewable wood pulp. Unlike synthetic polymers such as polyester, rayon PET breaks down more easily in the environment, reducing plastic pollution. Its natural origin provides breathability and softness, enhancing comfort compared to the often less breathable synthetic textiles.

Table of Comparison

| Feature | Regenerated Cellulose | Synthetic Polymer |

|---|---|---|

| Origin | Natural cellulose chemically regenerated | Petroleum-based or chemical synthesis |

| Biodegradability | Biodegradable and eco-friendly | Non-biodegradable, persistent |

| Fiber Type | Rayon, viscose, lyocell | Nylon, polyester, acrylic |

| Moisture Absorption | High moisture absorbency | Low moisture absorption |

| Comfort | Soft, breathable, comfortable | Less breathable, can cause discomfort |

| Durability | Moderate strength, weaker when wet | High strength, retains strength when wet |

| Environmental Impact | Lower, depends on chemical process | Higher, relies on fossil fuels |

| Cost | Moderate | Varies, often lower for mass production |

Introduction to Regenerated Cellulose and Synthetic Polymers

Regenerated cellulose fibers, derived from natural cellulose through chemical processing, offer biodegradability and excellent moisture absorption, making them favorable in sustainable textile applications. Synthetic polymers such as polyester and nylon are petroleum-based, engineered for high durability, elasticity, and resistance to environmental degradation, widely used in diverse industrial and consumer products. The fundamental difference lies in their origin and environmental impact, with regenerated cellulose promoting eco-friendly solutions compared to the synthetic polymer's reliance on fossil fuels.

Defining Rayon: The Classic Regenerated Cellulose Fiber

Rayon, a classic regenerated cellulose fiber, is produced by chemically processing natural cellulose from wood pulp or cotton linters, distinguishing it from synthetic polymers derived from petrochemicals. This fiber offers breathability, softness, and biodegradability, making it a sustainable alternative to fully synthetic fibers like polyester and nylon. Its ability to mimic natural fibers while providing versatile fabric characteristics positions rayon as a key material in the textile industry focused on eco-friendly solutions.

Origins and Manufacturing Processes

Regenerated cellulose fibers like rayon are derived from natural cellulose sources such as wood pulp or cotton linters, undergoing chemical treatment to convert cellulose into a soluble form before being spun into fibers. Synthetic polymers, in contrast, originate from petrochemical raw materials through polymerization processes that create entirely man-made fibers such as polyester or nylon. The manufacturing of regenerated cellulose involves environmentally sensitive chemical recovery systems, while synthetic polymer production relies heavily on energy-intensive petrochemical refining and catalysis.

Chemical Structure: Regenerated Cellulose vs Synthetic Polymer

Regenerated cellulose fibers, such as rayon, are composed of natural cellulose molecules chemically treated to break down and reform their structure, retaining hydroxyl groups that enable biodegradability and moisture absorption. Synthetic polymers like polyester consist of long hydrocarbon chains formed through petrochemical processes, characterized by ester or amide linkages that confer durability and resistance to biodegradation. The hydroxyl-rich chemical structure of regenerated cellulose allows for enhanced breathability and softness compared to the hydrophobic, non-polar backbone of most synthetic polymers.

Physical Properties and Performance Comparison

Regenerated cellulose fibers like rayon exhibit high moisture absorption, breathability, and excellent dye affinity compared to synthetic polymers such as polyester, which are hydrophobic and less breathable. Rayon offers superior comfort and softness due to its natural origin, while synthetic polymers provide greater durability, abrasion resistance, and elasticity. Performance-wise, synthetic polymers retain shape better under stress and dry faster, but rayon's biodegradability and biodegrading physical properties make it more environmentally friendly.

Sustainability and Environmental Impact

Regenerated cellulose fibers, such as rayon, offer a more sustainable alternative to synthetic polymers like polyester by being derived from renewable natural sources like wood pulp, which are biodegradable and reduce microplastic pollution. The production process of regenerated cellulose has evolved with closed-loop systems that recycle solvents and minimize environmental impact, contrasting sharply with the energy-intensive and petroleum-dependent synthesis of synthetic polymers. Despite challenges related to deforestation and chemical use, responsible sourcing and advances in eco-friendly processing make regenerated cellulose fibers a greener choice in textile manufacturing compared to synthetic polymers.

Applications in the Textile Industry

Regenerated cellulose fibers like rayon offer excellent breathability, moisture absorption, and biodegradability, making them ideal for comfortable and eco-friendly textiles such as apparel, upholstery, and home furnishings. Synthetic polymers like polyester provide superior durability, elasticity, and color retention, which suit performance wear, industrial fabrics, and technical textiles requiring high strength and resilience. The textile industry balances these materials by leveraging rayon's natural feel and sustainability and synthetic polymers' functional performance to meet diverse consumer and environmental demands.

Comfort, Biodegradability, and Wearability

Regenerated cellulose fibers, such as rayon, offer superior comfort due to their breathability and moisture absorption compared to synthetic polymers like polyester, which tend to trap heat and sweat. Biodegradability is a significant advantage of rayon, as it breaks down naturally in the environment, whereas synthetic polymers can persist for decades. In terms of wearability, rayon provides a soft, smooth texture and good drape, enhancing user comfort, while synthetic fibers often prioritize durability and stretch but may sacrifice natural feel.

Cost, Availability, and Market Trends

Regenerated cellulose fibers, derived from natural sources like wood pulp, offer a cost-effective alternative to synthetic polymers such as polyester and nylon, which rely on petrochemical processes and tend to have higher production expenses. Availability of regenerated cellulose is abundant due to renewable raw materials, supporting sustainable market demands, whereas synthetic polymers face volatility from fossil fuel price fluctuations and environmental regulations. Market trends indicate a growing preference for regenerated cellulose driven by eco-conscious consumers and stricter environmental policies, contributing to increased investment in sustainable fiber technology and a steady rise in production capacity.

Future Innovations in Fiber Technology

Future innovations in fiber technology emphasize the development of hybrid materials combining regenerated cellulose with synthetic polymers to enhance durability, moisture management, and environmental sustainability. Advanced biopolymers derived from renewable sources are being engineered to integrate with traditional rayon, offering improved biodegradability and performance. These breakthroughs aim to reduce dependency on petrochemical-based fibers while optimizing the functional properties of textiles for diverse applications.

Regenerated Cellulose vs Synthetic Polymer Infographic

materialdif.com

materialdif.com