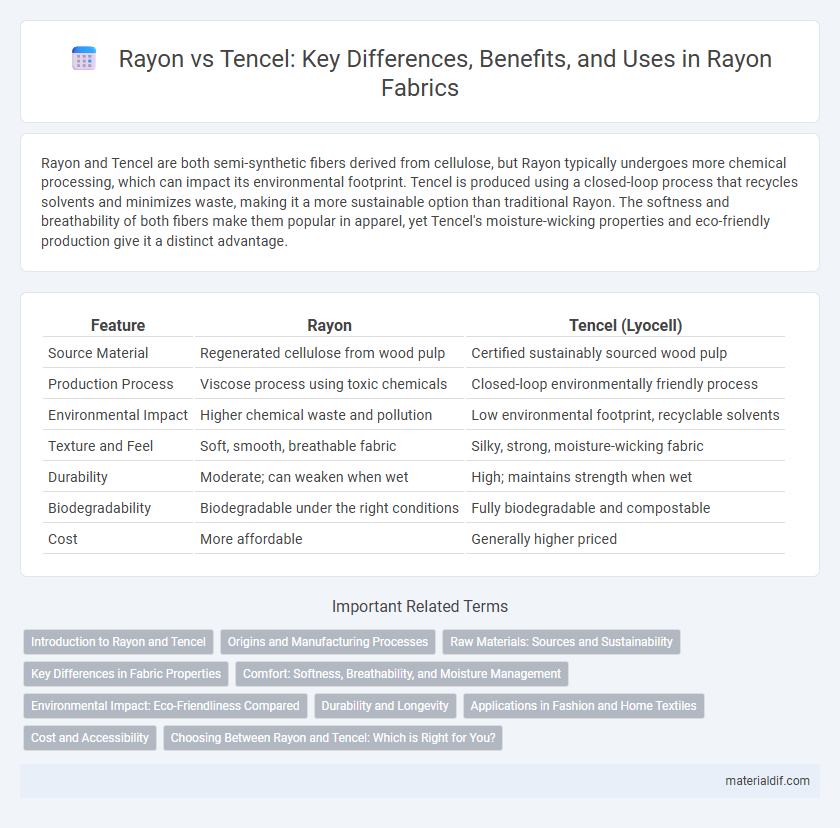

Rayon and Tencel are both semi-synthetic fibers derived from cellulose, but Rayon typically undergoes more chemical processing, which can impact its environmental footprint. Tencel is produced using a closed-loop process that recycles solvents and minimizes waste, making it a more sustainable option than traditional Rayon. The softness and breathability of both fibers make them popular in apparel, yet Tencel's moisture-wicking properties and eco-friendly production give it a distinct advantage.

Table of Comparison

| Feature | Rayon | Tencel (Lyocell) |

|---|---|---|

| Source Material | Regenerated cellulose from wood pulp | Certified sustainably sourced wood pulp |

| Production Process | Viscose process using toxic chemicals | Closed-loop environmentally friendly process |

| Environmental Impact | Higher chemical waste and pollution | Low environmental footprint, recyclable solvents |

| Texture and Feel | Soft, smooth, breathable fabric | Silky, strong, moisture-wicking fabric |

| Durability | Moderate; can weaken when wet | High; maintains strength when wet |

| Biodegradability | Biodegradable under the right conditions | Fully biodegradable and compostable |

| Cost | More affordable | Generally higher priced |

Introduction to Rayon and Tencel

Rayon, a semi-synthetic fiber made from cellulose, is renowned for its silk-like texture and breathability, commonly used in apparel and home textiles. Tencel, a branded form of lyocell produced from sustainably sourced wood pulp, offers enhanced moisture-wicking properties and eco-friendly manufacturing processes. Both fibers provide soft, comfortable fabrics, but Tencel stands out for its environmental benefits and superior durability.

Origins and Manufacturing Processes

Rayon is a semi-synthetic fiber derived from cellulose sources such as wood pulp, primarily produced through the viscose process involving chemical treatment to convert cellulose into a soluble compound. Tencel, a brand name for lyocell, originates from sustainably sourced eucalyptus trees and employs a closed-loop solvent spinning method that recycles water and solvents, dramatically reducing environmental impact. The key distinction lies in rayon's chemically intensive viscose production versus Tencel's eco-friendly, lower-toxicity manufacturing process.

Raw Materials: Sources and Sustainability

Rayon is primarily derived from wood pulp sourced from fast-growing trees such as beech, pine, and eucalyptus, often from commercial plantations that may contribute to deforestation concerns. Tencel, a branded form of lyocell produced by Lenzing, uses sustainably sourced eucalyptus trees grown on certified forests with eco-friendly practices, including closed-loop production that recycles water and solvents. The sustainable forestry management and lower environmental impact of Tencel's raw materials position it as a more eco-conscious alternative compared to traditional rayon manufacturing.

Key Differences in Fabric Properties

Rayon is a semi-synthetic fiber derived from cellulose, offering a soft and breathable texture with moderate moisture absorption, while Tencel, a branded type of lyocell, provides superior moisture-wicking capabilities and enhanced durability due to its closed-loop production process. Rayon tends to wrinkle more easily and may lose strength when wet, whereas Tencel maintains better structural integrity and resists shrinking and pilling. The eco-friendly manufacturing of Tencel results in less environmental impact compared to traditional rayon, making it a preferred choice for sustainable fabric applications.

Comfort: Softness, Breathability, and Moisture Management

Rayon and Tencel differ significantly in comfort attributes such as softness, breathability, and moisture management. Rayon offers a smooth, silky texture with moderate breathability, making it comfortable in warm conditions but prone to trapping moisture. Tencel excels in moisture management due to its unique fiber structure, providing superior breathability and a softer feel that enhances overall comfort and keeps skin dry.

Environmental Impact: Eco-Friendliness Compared

Rayon production involves significant chemical use and water pollution, making it less eco-friendly compared to Tencel, which is manufactured using a closed-loop process that recycles solvents and minimizes waste. Tencel fibers come from sustainably sourced eucalyptus trees, requiring less water and pesticides, further reducing its environmental footprint. The sustainable practices in Tencel production lead to lower greenhouse gas emissions and improved biodegradability compared to traditional rayon.

Durability and Longevity

Rayon offers moderate durability with a tendency to weaken when wet, making it less suited for long-term or heavy-duty use compared to Tencel. Tencel, made from sustainably sourced eucalyptus fibers, boasts superior strength and resilience, maintaining its integrity even after multiple washes. Its natural moisture-wicking properties further enhance longevity, making Tencel a more durable and eco-friendly choice over traditional rayon fabrics.

Applications in Fashion and Home Textiles

Rayon and Tencel are widely used in fashion and home textiles due to their breathability and softness, with rayon favored for its silk-like feel and affordability in casual wear and upholstery. Tencel, derived from sustainably sourced wood pulp, excels in moisture management and durability, making it ideal for activewear, bedding, and eco-friendly interior fabrics. Both fibers enhance comfort and sustainability but differ in environmental impact and performance characteristics.

Cost and Accessibility

Rayon generally costs less than Tencel due to simpler production methods, making it more accessible for mass-market clothing and textiles. Tencel, derived from sustainably sourced wood pulp through a more complex and eco-friendly process, commands higher prices but offers superior environmental benefits. Brands seeking budget-friendly options often prefer Rayon, while those prioritizing sustainability invest in Tencel despite its higher cost.

Choosing Between Rayon and Tencel: Which is Right for You?

Rayon and Tencel, both semi-synthetic fibers derived from cellulose, differ significantly in sustainability and performance. Rayon offers softness and breathability but often involves environmentally harmful production processes, whereas Tencel is produced via a closed-loop system minimizing chemical waste and excels in moisture management and durability. Choosing between Rayon and Tencel depends on prioritizing eco-friendliness and long-lasting wear versus cost-effectiveness and softness.

Rayon vs Tencel Infographic

materialdif.com

materialdif.com