Bio-based polyester offers a sustainable alternative to conventional polyester by utilizing renewable resources such as plant-based materials, reducing reliance on fossil fuels. It maintains similar performance and durability while significantly lowering carbon emissions and environmental impact during production. This innovation supports circular economy efforts and promotes eco-friendly textile manufacturing.

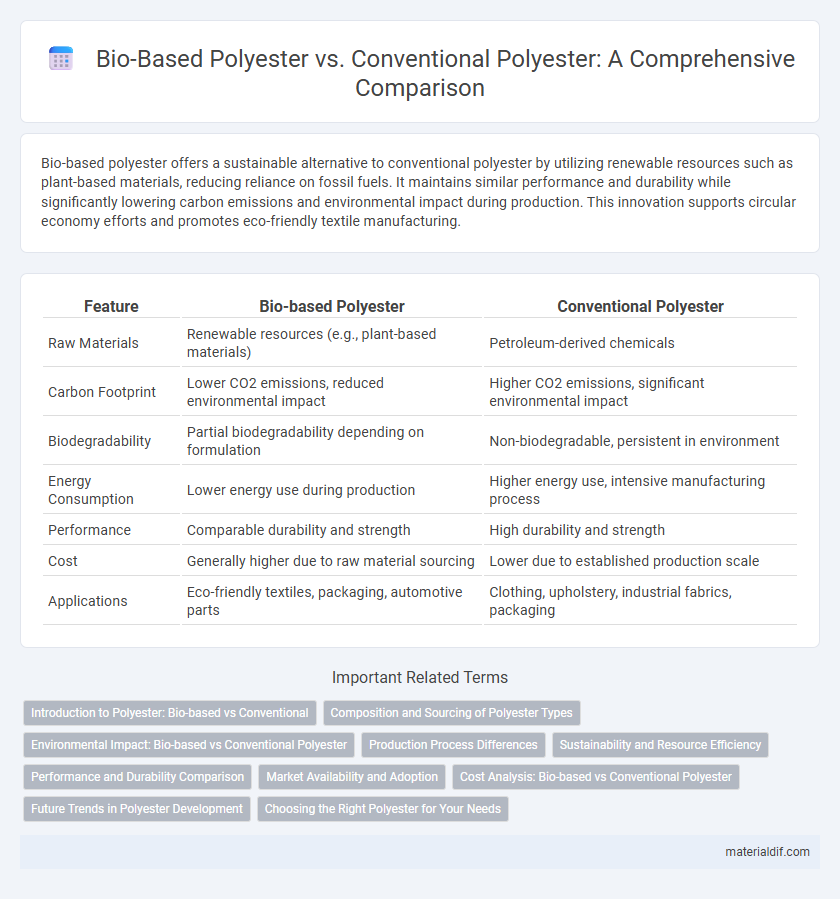

Table of Comparison

| Feature | Bio-based Polyester | Conventional Polyester |

|---|---|---|

| Raw Materials | Renewable resources (e.g., plant-based materials) | Petroleum-derived chemicals |

| Carbon Footprint | Lower CO2 emissions, reduced environmental impact | Higher CO2 emissions, significant environmental impact |

| Biodegradability | Partial biodegradability depending on formulation | Non-biodegradable, persistent in environment |

| Energy Consumption | Lower energy use during production | Higher energy use, intensive manufacturing process |

| Performance | Comparable durability and strength | High durability and strength |

| Cost | Generally higher due to raw material sourcing | Lower due to established production scale |

| Applications | Eco-friendly textiles, packaging, automotive parts | Clothing, upholstery, industrial fabrics, packaging |

Introduction to Polyester: Bio-based vs Conventional

Bio-based polyester is derived from renewable plant materials such as corn glucose, reducing reliance on fossil fuels and lowering carbon emissions compared to conventional polyester, which is produced from petroleum-based petrochemicals. Conventional polyester, primarily polyethylene terephthalate (PET), dominates the textile and packaging industries due to its durability, cost-effectiveness, and widespread availability. Advances in bio-based polyester technology aim to match the performance characteristics of conventional polyester while promoting sustainability and reducing environmental impact.

Composition and Sourcing of Polyester Types

Bio-based polyester is primarily derived from renewable plant-based resources such as corn glucose or sugarcane, while conventional polyester is synthesized from petrochemical products like petroleum and natural gas. The molecular structure of both types consists mainly of repeating ester units, but bio-based polyester incorporates biomass-derived monomers that reduce reliance on fossil fuels. Sourcing bio-based polyester supports sustainability by utilizing agricultural feedstocks, whereas conventional polyester depends on non-renewable fossil fuel extraction processes.

Environmental Impact: Bio-based vs Conventional Polyester

Bio-based polyester significantly reduces greenhouse gas emissions by utilizing renewable resources instead of fossil fuels, lowering its carbon footprint compared to conventional polyester. It enhances biodegradability and decreases dependency on non-renewable petrochemicals, contributing to reduced environmental pollution and resource depletion. Conventional polyester, derived from petroleum, generates higher energy consumption and microplastic pollution, intensifying ecological harm throughout its lifecycle.

Production Process Differences

Bio-based polyester is produced using renewable raw materials such as plant-derived sugars, which undergo fermentation and polymerization processes to create sustainable polymers, reducing reliance on fossil fuels. Conventional polyester relies on petrochemical feedstocks derived from crude oil, involving energy-intensive processes like naphtha cracking and polymerization that emit higher greenhouse gases. The bio-based production process emphasizes lower carbon footprints and biodegradable potential, contrasting with the conventional method's dependency on non-renewable resources and environmental concerns.

Sustainability and Resource Efficiency

Bio-based polyester, derived from renewable resources such as plant-based materials, offers enhanced sustainability by reducing reliance on fossil fuels and lowering carbon emissions compared to conventional polyester, which is petroleum-based. The production of bio-based polyester typically consumes less energy and water, contributing to better resource efficiency and a smaller environmental footprint. While conventional polyester remains dominant due to established manufacturing processes, shifting towards bio-based alternatives supports circular economy principles and mitigates plastic pollution.

Performance and Durability Comparison

Bio-based polyester exhibits comparable tensile strength and elasticity to conventional polyester, ensuring similar performance standards in textiles and industrial applications. Both materials offer high resistance to abrasion, UV exposure, and chemical degradation, with bio-based variants often enhancing sustainability without compromising durability. Lifecycle assessments indicate bio-based polyester maintains structural integrity over prolonged use, matching the resilience and wear resistance typical of conventional polyester fibers.

Market Availability and Adoption

Bio-based polyester is gaining traction in the market due to increasing demand for sustainable materials, with major brands incorporating it into their supply chains to reduce carbon footprints. Conventional polyester, derived from petrochemicals, remains more widely available and cost-effective, dominating global production and use across textiles and packaging industries. Market adoption of bio-based polyester is growing steadily but still lags behind conventional polyester, hindered by higher production costs and limited large-scale manufacturing facilities.

Cost Analysis: Bio-based vs Conventional Polyester

Bio-based polyester typically incurs higher production costs due to the use of renewable raw materials and less mature manufacturing processes compared to conventional polyester, which benefits from established petrochemical supply chains and economies of scale. Conventional polyester remains cost-competitive with a lower market price, driven by abundant fossil fuel feedstocks and optimized large-scale production. Despite higher initial costs, bio-based polyester offers potential long-term savings through reduced environmental impact and alignment with increasing regulatory incentives for sustainable materials.

Future Trends in Polyester Development

Bio-based polyester, derived from renewable resources such as plant-based sugars, offers a sustainable alternative to conventional polyester, which relies heavily on petroleum-based raw materials. Future trends in polyester development emphasize enhancing biodegradability, reducing carbon footprints through advanced bio-polymerization techniques, and integrating circular economy principles like chemical recycling. Innovations in enzyme-catalyzed polymer synthesis and genetically engineered feedstocks are expected to drive the transition toward eco-friendly polyester production at industrial scales.

Choosing the Right Polyester for Your Needs

Bio-based polyester, derived from renewable resources such as plant-based materials, offers a reduced carbon footprint and enhanced biodegradability compared to conventional polyester made from petroleum derivatives. Selecting the right polyester depends on factors like environmental impact, performance requirements, and lifecycle sustainability, with bio-based options favoring eco-conscious applications. Conventional polyester remains dominant for cost-efficiency and durability, but bio-based polyester presents a valuable alternative for industries prioritizing green innovation and reduced fossil fuel dependence.

Bio-based Polyester vs Conventional Polyester Infographic

materialdif.com

materialdif.com