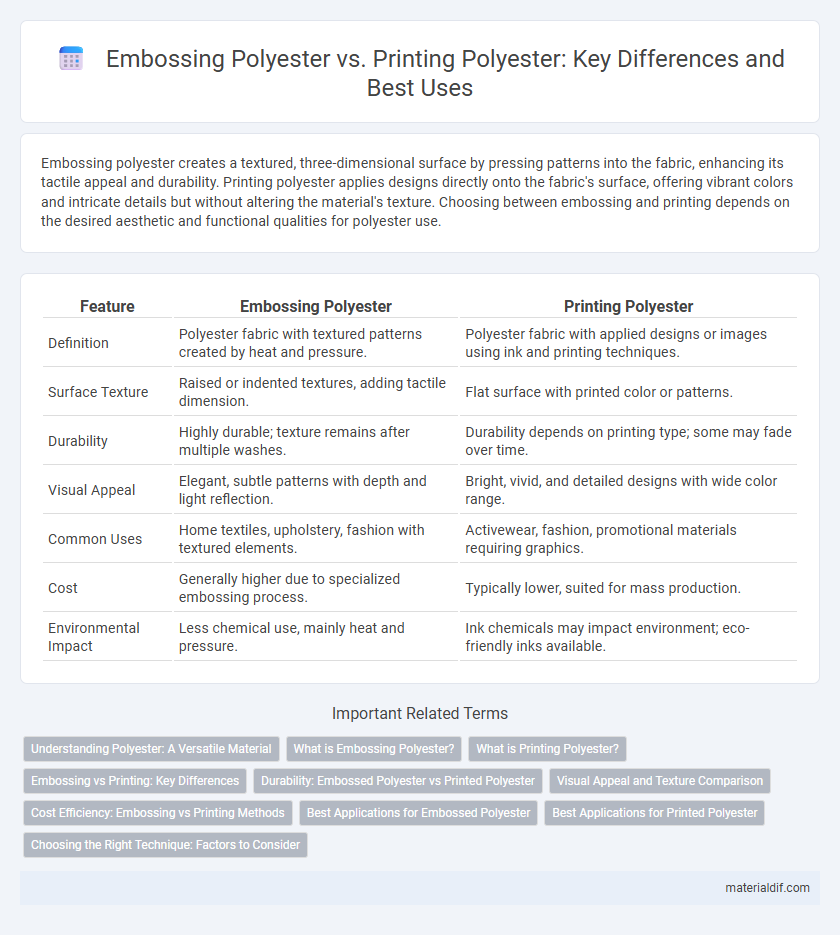

Embossing polyester creates a textured, three-dimensional surface by pressing patterns into the fabric, enhancing its tactile appeal and durability. Printing polyester applies designs directly onto the fabric's surface, offering vibrant colors and intricate details but without altering the material's texture. Choosing between embossing and printing depends on the desired aesthetic and functional qualities for polyester use.

Table of Comparison

| Feature | Embossing Polyester | Printing Polyester |

|---|---|---|

| Definition | Polyester fabric with textured patterns created by heat and pressure. | Polyester fabric with applied designs or images using ink and printing techniques. |

| Surface Texture | Raised or indented textures, adding tactile dimension. | Flat surface with printed color or patterns. |

| Durability | Highly durable; texture remains after multiple washes. | Durability depends on printing type; some may fade over time. |

| Visual Appeal | Elegant, subtle patterns with depth and light reflection. | Bright, vivid, and detailed designs with wide color range. |

| Common Uses | Home textiles, upholstery, fashion with textured elements. | Activewear, fashion, promotional materials requiring graphics. |

| Cost | Generally higher due to specialized embossing process. | Typically lower, suited for mass production. |

| Environmental Impact | Less chemical use, mainly heat and pressure. | Ink chemicals may impact environment; eco-friendly inks available. |

Understanding Polyester: A Versatile Material

Embossing polyester involves creating raised patterns on the fabric surface through heat and pressure, enhancing texture and durability without compromising the material's inherent strength. Printing polyester uses dye-sublimation or screen printing techniques to apply vibrant, long-lasting colors that bond with the synthetic fibers for detailed designs. Both methods leverage polyester's versatility, making it suitable for diverse applications in fashion, upholstery, and industrial uses.

What is Embossing Polyester?

Embossing polyester involves creating raised patterns or textures on the fabric surface using heat and pressure, enhancing the material's tactile and visual appeal. This technique permanently alters the polyester's surface without affecting its structural integrity, making it ideal for decorative applications in fashion and interiors. Unlike printing polyester, which applies color or designs onto the fabric, embossing modifies the fabric's texture for a dimensional effect.

What is Printing Polyester?

Printing polyester involves applying dyes or pigments onto the fabric's surface to create vibrant, detailed designs with high colorfastness and crisp resolution. This technique utilizes screen printing, digital printing, or sublimation, allowing complex patterns and multiple colors to be rendered accurately. Printing polyester enhances fabric customization for fashion, sportswear, and promotional textiles while maintaining the material's durability and wrinkle resistance.

Embossing vs Printing: Key Differences

Embossing polyester creates a textured, three-dimensional surface by pressing patterns into the fabric, enhancing tactile appeal and durability without altering the color. Printing polyester applies ink or dye onto the fabric surface, producing vivid, customizable designs but maintaining a smooth texture. Embossing offers long-lasting surface modification ideal for structural effects, while printing provides versatile color options suitable for varied artistic expression.

Durability: Embossed Polyester vs Printed Polyester

Embossed polyester exhibits superior durability compared to printed polyester due to the textured surface being physically pressed into the fabric, which resists fading and wear over time. Printed polyester relies on ink or dye applied to the fabric's surface, making it more susceptible to cracking, peeling, and color loss through repeated washing and exposure to sunlight. This inherent strength makes embossed polyester a preferred choice for applications demanding long-lasting visual appeal and structural integrity.

Visual Appeal and Texture Comparison

Embossing polyester enhances visual appeal by creating raised patterns that add tactile texture and depth, making designs stand out with a three-dimensional effect. Printing polyester offers vibrant, detailed images with a smooth surface but lacks the physical texture present in embossing. Embossed garments provide a unique sensory experience and durability in design, while printed polyester excels in color precision and intricate graphics.

Cost Efficiency: Embossing vs Printing Methods

Embossing polyester involves creating raised patterns using heat and pressure, resulting in a durable, textured finish with minimal ink usage and lower material waste, making it more cost-efficient for bulk production. Printing polyester requires inks and multiple processing steps, increasing expenses related to materials, labor, and potential rework due to misprints or color inconsistencies. For large-scale applications, embossing reduces ongoing consumable costs while maintaining quality, whereas printing offers greater design versatility but higher operational costs.

Best Applications for Embossed Polyester

Embossed polyester offers enhanced texture and depth, making it ideal for luxury apparel, upholstery, and home decor where tactile appeal is essential. This technique accentuates the fabric's dimensionality without compromising durability, perfect for fashion designers seeking unique surface finishes or interior designers requiring sophisticated fabric patterns. Embossing polyester improves visual interest and structural integrity, outperforming printing in applications demanding long-lasting texture and subtle elegance.

Best Applications for Printed Polyester

Printed polyester excels in applications requiring detailed graphics, vibrant colors, and flexibility, such as sportswear, promotional banners, and fashion textiles. The printing process allows for high-resolution images and complex patterns that maintain durability and colorfastness under repeated washing and exposure to sunlight. Optimal for custom designs, printed polyester is preferred in environments demanding both aesthetic appeal and functional performance.

Choosing the Right Technique: Factors to Consider

Embossing polyester creates textured patterns by pressing designs into the fabric, enhancing durability and adding tactile depth, while printing polyester applies color directly onto the surface for vibrant and detailed visuals. Factors to consider include the desired aesthetic effect, usage environment, and production cost, as embossing is ideal for subtle, long-lasting designs and printing excels in complex, colorful images. Selecting the right technique depends on balancing fabric performance requirements with the visual impact needed for applications like fashion, upholstery, or branding.

Embossing Polyester vs Printing Polyester Infographic

materialdif.com

materialdif.com