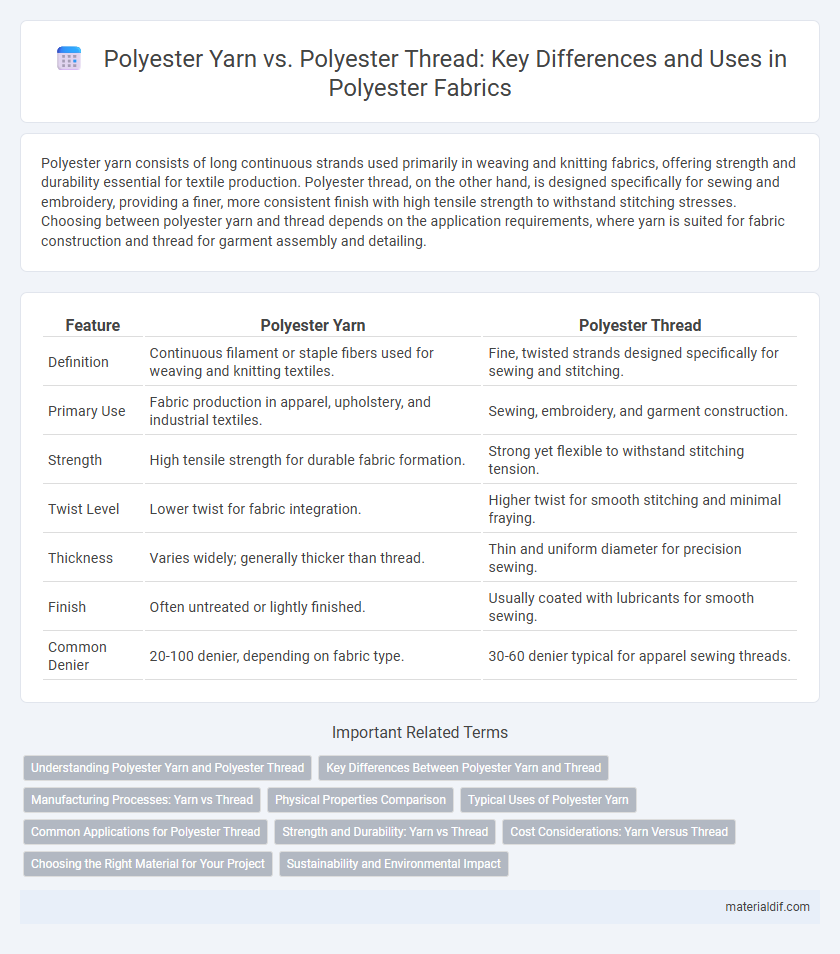

Polyester yarn consists of long continuous strands used primarily in weaving and knitting fabrics, offering strength and durability essential for textile production. Polyester thread, on the other hand, is designed specifically for sewing and embroidery, providing a finer, more consistent finish with high tensile strength to withstand stitching stresses. Choosing between polyester yarn and thread depends on the application requirements, where yarn is suited for fabric construction and thread for garment assembly and detailing.

Table of Comparison

| Feature | Polyester Yarn | Polyester Thread |

|---|---|---|

| Definition | Continuous filament or staple fibers used for weaving and knitting textiles. | Fine, twisted strands designed specifically for sewing and stitching. |

| Primary Use | Fabric production in apparel, upholstery, and industrial textiles. | Sewing, embroidery, and garment construction. |

| Strength | High tensile strength for durable fabric formation. | Strong yet flexible to withstand stitching tension. |

| Twist Level | Lower twist for fabric integration. | Higher twist for smooth stitching and minimal fraying. |

| Thickness | Varies widely; generally thicker than thread. | Thin and uniform diameter for precision sewing. |

| Finish | Often untreated or lightly finished. | Usually coated with lubricants for smooth sewing. |

| Common Denier | 20-100 denier, depending on fabric type. | 30-60 denier typical for apparel sewing threads. |

Understanding Polyester Yarn and Polyester Thread

Polyester yarn is a continuous strand of interlocked polyester fibers used primarily in fabric weaving and knitting, offering strength and durability for textile production. Polyester thread, made from finer polyester filaments, is designed specifically for sewing and stitching purposes, providing high tensile strength and resistance to abrasion. Understanding the distinction between polyester yarn and thread is essential for selecting the right material based on application needs in manufacturing or garment construction.

Key Differences Between Polyester Yarn and Thread

Polyester yarn consists of long continuous strands used primarily for weaving and knitting fabrics, offering strength and durability in textiles. Polyester thread, thinner and stronger, is specifically designed for sewing applications to join fabric pieces together with high tensile strength and resistance to abrasion. The key difference lies in their intended use--yarn forms the fabric structure, while thread is meant for stitching and finishing garments.

Manufacturing Processes: Yarn vs Thread

Polyester yarn is produced through a spinning process where continuous filaments of polyester fibers are twisted together to form long, strong strands used primarily in weaving and knitting fabrics. Polyester thread undergoes further refinement steps such as texturizing, polishing, and winding to create a finer, smoother, and more consistent product ideal for sewing applications. Manufacturing polyester thread demands higher precision in tension control and uniformity compared to polyester yarn, reflecting its functional differences in textile production.

Physical Properties Comparison

Polyester yarn typically has higher tensile strength and elongation compared to polyester thread, making it more durable for fabric production. The yarn's thickness is greater, providing better bulk and texture, while polyester thread is finer and smoother, ideal for precise stitching and minimal seam bulk. Both materials exhibit excellent resistance to abrasion and moisture, but yarn tends to offer superior resilience for heavy-duty textile applications.

Typical Uses of Polyester Yarn

Polyester yarn is commonly used in textiles for apparel, upholstery, and industrial fabrics due to its durability, strength, and resistance to shrinking and stretching. It is ideal for knitting, weaving, and crafting applications where flexibility and color retention are essential. In contrast, polyester thread is primarily designed for sewing and stitching, providing strong, smooth seams in garment construction and home textiles.

Common Applications for Polyester Thread

Polyester thread is primarily used in sewing, embroidery, and upholstery due to its strength, elasticity, and resistance to shrinking and abrasion. Unlike polyester yarn, which is often utilized in fabric production and knitting, polyester thread is ideal for high-stress seams and decorative stitching on various textile products. Common applications include garment construction, automotive interiors, outdoor gear, and home furnishings.

Strength and Durability: Yarn vs Thread

Polyester yarn offers superior tensile strength due to its thicker fibers and twisted construction, making it ideal for heavy-duty fabric applications. Polyester thread, while made from similar material, is finer and designed to withstand sewing machine tension without breaking, providing excellent seam durability. Both provide high resistance to abrasion and chemicals, but yarn's structure ensures greater overall durability in textiles compared to thread.

Cost Considerations: Yarn Versus Thread

Polyester yarn generally costs less per unit than polyester thread due to its bulk production for diverse textile applications, while polyester thread incurs higher manufacturing expenses because of its specialized spinning and finishing processes that enhance strength and durability. The price difference also reflects variations in material weight and tensile properties, with polyester thread often requiring finer filtration and tighter twisting, raising production complexity. Budget-conscious buyers should weigh project requirements, as polyester yarn suits general fabric weaving at a lower cost, whereas polyester thread justifies its premium for sewing and stitching tasks demanding enhanced performance.

Choosing the Right Material for Your Project

Polyester yarn and polyester thread differ primarily in thickness, strength, and intended use, making the choice dependent on your project's requirements. Polyester yarn offers greater thickness and durability, ideal for knitting, weaving, or crafting textile products that demand flexibility and resilience. Polyester thread, being finer and stronger, is suited for sewing and stitching tasks, providing precise seams and lasting durability in garment construction or repairs.

Sustainability and Environmental Impact

Polyester yarn and polyester thread both originate from petrochemical sources, contributing to environmental concerns such as non-biodegradability and microplastic pollution. Polyester yarn, often produced in bulk for textiles, typically involves higher energy and water consumption during manufacturing compared to polyester thread, which is finer and used for stitching. Innovations in recycled polyester yarn, such as using PET bottles, offer improved sustainability by reducing waste and lowering carbon footprints relative to traditional polyester thread production methods.

Polyester Yarn vs Polyester Thread Infographic

materialdif.com

materialdif.com