Cationic polyester features enhanced dye affinity and brighter color retention compared to regular polyester due to its positively charged molecular structure. This unique property allows cationic polyester to absorb disperse dyes more efficiently, resulting in more vivid and long-lasting hues. Regular polyester, while durable and widely used, often requires additional chemical treatments to achieve similar color vibrancy and fastness.

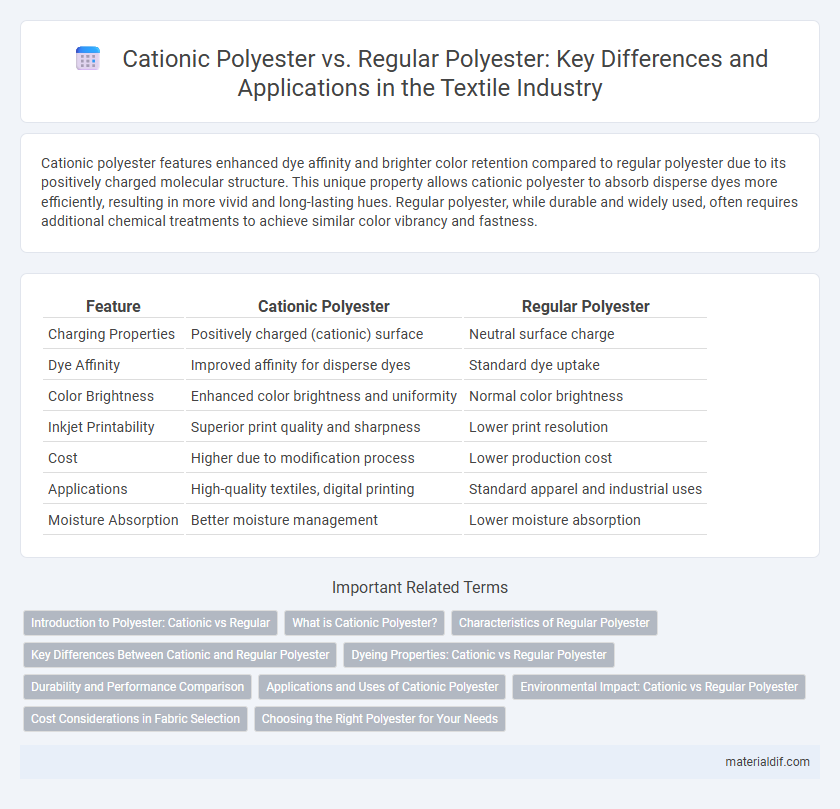

Table of Comparison

| Feature | Cationic Polyester | Regular Polyester |

|---|---|---|

| Charging Properties | Positively charged (cationic) surface | Neutral surface charge |

| Dye Affinity | Improved affinity for disperse dyes | Standard dye uptake |

| Color Brightness | Enhanced color brightness and uniformity | Normal color brightness |

| Inkjet Printability | Superior print quality and sharpness | Lower print resolution |

| Cost | Higher due to modification process | Lower production cost |

| Applications | High-quality textiles, digital printing | Standard apparel and industrial uses |

| Moisture Absorption | Better moisture management | Lower moisture absorption |

Introduction to Polyester: Cationic vs Regular

Cationic polyester features a modified molecular structure that enhances dye affinity and improves color vibrancy compared to regular polyester, which exhibits lower dye absorption due to its non-ionic nature. Regular polyester is widely recognized for its durability, wrinkle resistance, and moisture-wicking properties, making it a staple in textile manufacturing. The introduction of cationic polyester addresses common challenges in coloration and fabric performance, offering advanced options for high-quality, eco-friendly textile production.

What is Cationic Polyester?

Cationic polyester is a type of polyester fiber modified with positively charged ions to enhance dye affinity and moisture absorption, distinguishing it from regular polyester, which is hydrophobic and less dye-retentive. This modification improves cationic polyester's dyeability with disperse dyes, resulting in vibrant colors and better colorfastness. Its unique molecular structure leads to increased comfort and functionality in textile applications compared to conventional polyester.

Characteristics of Regular Polyester

Regular polyester, primarily made from polyethylene terephthalate (PET), is known for its durability, wrinkle resistance, and quick-drying properties, making it ideal for diverse textile applications. It has a relatively low moisture absorption rate, which can result in less comfort during wear but enhances its resistance to mildew and stains. The fiber's strength, resilience, and ability to retain shape under stress contribute to its widespread use in apparel, upholstery, and industrial fabrics.

Key Differences Between Cationic and Regular Polyester

Cationic polyester differs from regular polyester primarily in its dyeability, as it contains positively charged sites that attract anionic dyes, resulting in brighter colors and improved colorfastness. Regular polyester is hydrophobic and typically requires disperse dyes, which offer less vibrant shades and reduced dye uptake. The molecular structure of cationic polyester allows for enhanced moisture absorption, making it more comfortable for textile applications compared to the standard hydrophobic nature of regular polyester.

Dyeing Properties: Cationic vs Regular Polyester

Cationic polyester fibers exhibit superior dyeing properties compared to regular polyester due to their modified chemical structure, allowing for enhanced affinity to cationic dyes and resulting in more vibrant, uniform coloration. Regular polyester typically requires disperse dyes and high-temperature dyeing processes, which can limit color intensity and increase energy consumption. The improved dye uptake of cationic polyester reduces the need for harsh dyeing conditions and offers better colorfastness and environmental sustainability.

Durability and Performance Comparison

Cationic polyester exhibits superior durability compared to regular polyester due to its enhanced resistance to abrasion, UV degradation, and chemical exposure. The cationic modification improves moisture-wicking and dye affinity, resulting in better colorfastness and reduced fading over time. This performance upgrade makes cationic polyester ideal for athletic wear and outdoor applications requiring long-lasting fabric strength and vibrant appearance.

Applications and Uses of Cationic Polyester

Cationic polyester offers enhanced dye affinity and superior moisture management, making it ideal for activewear and performance textiles requiring vibrant colors and quick-drying properties. This polyester variant is widely used in sportswear, swimwear, and intimate apparel due to its improved comfort and durability compared to regular polyester. Its ability to blend well with other fibers also supports applications in fashion and technical fabrics where colorfastness and fabric resilience are critical.

Environmental Impact: Cationic vs Regular Polyester

Cationic polyester demonstrates a lower environmental impact compared to regular polyester due to its enhanced dye affinity, which reduces water consumption and chemical waste during the dyeing process. Regular polyester typically requires higher energy inputs and more toxic chemicals for dyeing, contributing to greater water pollution and carbon emissions. The sustainable manufacturing of cationic polyester supports reduced ecological footprints in textile production.

Cost Considerations in Fabric Selection

Cationic polyester typically incurs higher production costs compared to regular polyester due to specialized dyeing processes and the use of advanced cationic dyes, impacting overall fabric price. In contrast, regular polyester benefits from established manufacturing techniques and widespread availability, making it a more cost-effective choice for mass production. Fabric selection decisions often weigh the enhanced colorfastness and vibrancy of cationic polyester against budget constraints favoring regular polyester.

Choosing the Right Polyester for Your Needs

Cationic polyester features enhanced dye affinity and vibrant color retention compared to regular polyester, making it ideal for applications requiring bright, long-lasting hues. Regular polyester offers superior durability and moisture resistance, suited for heavy-use textiles and outdoor gear. Selecting the right polyester depends on balancing color vibrancy needs with fabric performance requirements in specific end-use scenarios.

Cationic Polyester vs Regular Polyester Infographic

materialdif.com

materialdif.com