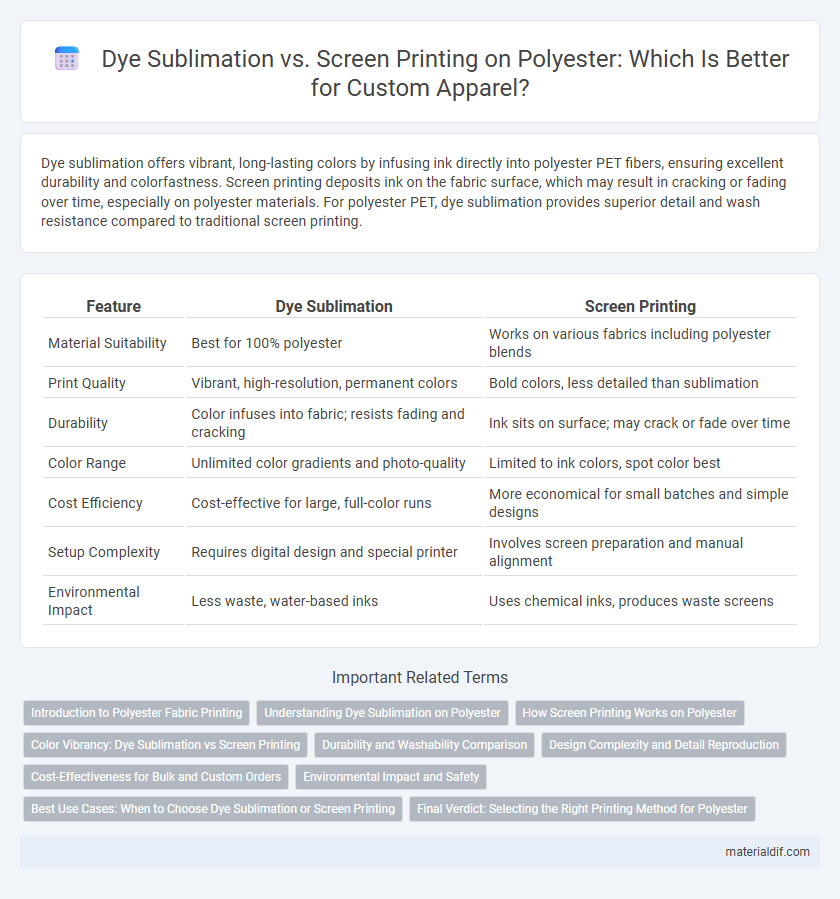

Dye sublimation offers vibrant, long-lasting colors by infusing ink directly into polyester PET fibers, ensuring excellent durability and colorfastness. Screen printing deposits ink on the fabric surface, which may result in cracking or fading over time, especially on polyester materials. For polyester PET, dye sublimation provides superior detail and wash resistance compared to traditional screen printing.

Table of Comparison

| Feature | Dye Sublimation | Screen Printing |

|---|---|---|

| Material Suitability | Best for 100% polyester | Works on various fabrics including polyester blends |

| Print Quality | Vibrant, high-resolution, permanent colors | Bold colors, less detailed than sublimation |

| Durability | Color infuses into fabric; resists fading and cracking | Ink sits on surface; may crack or fade over time |

| Color Range | Unlimited color gradients and photo-quality | Limited to ink colors, spot color best |

| Cost Efficiency | Cost-effective for large, full-color runs | More economical for small batches and simple designs |

| Setup Complexity | Requires digital design and special printer | Involves screen preparation and manual alignment |

| Environmental Impact | Less waste, water-based inks | Uses chemical inks, produces waste screens |

Introduction to Polyester Fabric Printing

Polyester fabric printing primarily utilizes dye sublimation and screen printing techniques, each offering distinct advantages for vibrant and durable designs. Dye sublimation excels in producing high-resolution, full-color images by infusing ink directly into the polyester fibers, resulting in breathable and long-lasting prints. Screen printing, while less vivid for complex designs, provides cost-effective solutions with excellent opacity and durability on polyester materials.

Understanding Dye Sublimation on Polyester

Dye sublimation on polyester involves a heat transfer process where dye turns into gas and bonds with synthetic fibers, creating vibrant, durable, and wash-resistant prints. This method is ideal for polyester fabrics due to their chemical structure, which allows the dye to penetrate deeply without cracking or fading. Compared to screen printing, dye sublimation offers superior color vibrancy and detail, making it the preferred choice for high-quality, full-color polyester apparel.

How Screen Printing Works on Polyester

Screen printing on polyester involves applying vibrant, durable ink through a fine mesh stencil onto the fabric's surface, creating sharp and long-lasting designs. Specialized plastisol or water-based inks are used to ensure excellent adhesion and color vibrancy on synthetic fibers like polyester. The process includes curing the ink under heat, which bonds it firmly to the polyester, resulting in fade-resistant prints ideal for apparel and promotional items.

Color Vibrancy: Dye Sublimation vs Screen Printing

Dye sublimation produces exceptionally vibrant and long-lasting colors on polyester fabrics by infusing dye directly into the fibers, resulting in a smooth, photo-realistic finish. Screen printing applies layers of ink on top of the fabric, which can lead to more vivid, opaque colors but may feel heavier and less breathable. For polyester, dye sublimation generally offers superior color vibrancy and durability, especially for complex and full-color designs.

Durability and Washability Comparison

Dye sublimation offers superior durability on polyester fabrics because the ink penetrates the fibers, resulting in vibrant, long-lasting prints that withstand repeated washing without fading or cracking. Screen printing, while effective for bold colors, tends to sit on the fabric's surface and may degrade over time, leading to fading and cracking after multiple wash cycles. Polyester garments printed via dye sublimation maintain their quality and color integrity significantly better when subjected to frequent laundering compared to those printed with screen printing techniques.

Design Complexity and Detail Reproduction

Dye sublimation offers superior design complexity and detail reproduction on polyester, allowing for vibrant, full-color images with intricate gradients and fine lines that penetrate the fabric for a smooth, durable finish. Screen printing, while effective for bold, solid colors and simple designs, often struggles with detailed patterns and multicolor gradients due to limited color layering capabilities. For highly detailed, photorealistic prints on polyester, dye sublimation remains the preferred method due to its precision and color fidelity.

Cost-Effectiveness for Bulk and Custom Orders

Dye sublimation offers superior cost-effectiveness for bulk orders on polyester due to its ability to produce vibrant, full-color designs without additional setup fees. Screen printing becomes more economical for custom or smaller runs when using limited colors, as the initial setup costs and stencil creation increase with design complexity. Businesses should evaluate order size and design intricacy to optimize printing costs and material efficiency on polyester fabrics.

Environmental Impact and Safety

Dye sublimation on polyester emits fewer volatile organic compounds (VOCs) and minimizes water usage compared to screen printing, reducing environmental pollution. Screen printing often involves the use of plastisol inks containing harmful chemicals that require chemical solvents for cleanup, posing greater risks to workers' health and the environment. The water-based inks in dye sublimation are safer for both human exposure and aquatic ecosystems, making it a greener choice for polyester textile printing.

Best Use Cases: When to Choose Dye Sublimation or Screen Printing

Dye sublimation is best suited for polyester fabrics, especially for all-over prints or intricate designs requiring vibrant, long-lasting colors. Screen printing excels on cotton and blends, offering cost-effective solutions for bulk orders with simpler designs and fewer colors. Choose dye sublimation for performance wear or custom fashion where detail and durability matter, and screen printing for promotional items or large runs with bold, solid-colored graphics.

Final Verdict: Selecting the Right Printing Method for Polyester

Dye sublimation offers vibrant, long-lasting colors with excellent fabric breathability, ideal for polyester garments requiring detailed, full-color designs. Screen printing provides cost-effective durability and bold opacity, suitable for larger production runs with simpler color schemes on polyester. Choosing the right method depends on design complexity, budget, and desired fabric feel for optimal polyester garment printing results.

Dye Sublimation vs Screen Printing Infographic

materialdif.com

materialdif.com