Polyester yarn-dyed fabric offers enhanced colorfastness and durability by dyeing the fibers before weaving, resulting in vibrant, long-lasting patterns. In contrast, polyester piece-dyed fabric is dyed after weaving, which allows for quicker production and more uniform solid colors but may sacrifice some color intensity and resistance to fading. Choosing between yarn-dyed and piece-dyed polyester depends on the desired texture, design complexity, and performance requirements of the final textile product.

Table of Comparison

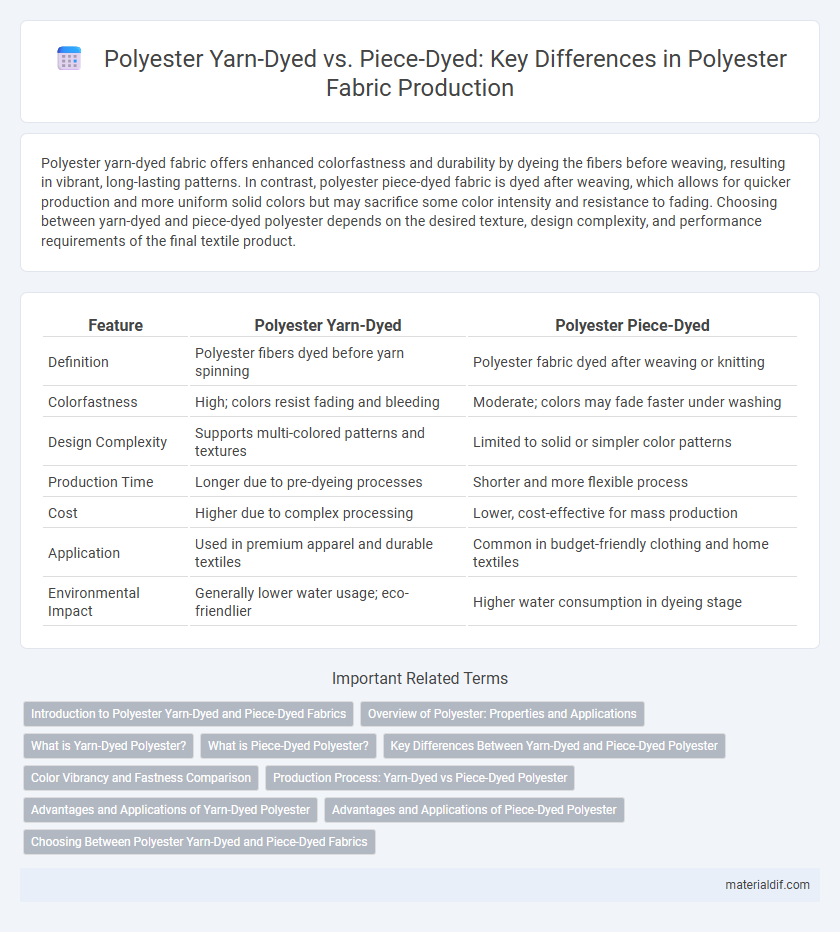

| Feature | Polyester Yarn-Dyed | Polyester Piece-Dyed |

|---|---|---|

| Definition | Polyester fibers dyed before yarn spinning | Polyester fabric dyed after weaving or knitting |

| Colorfastness | High; colors resist fading and bleeding | Moderate; colors may fade faster under washing |

| Design Complexity | Supports multi-colored patterns and textures | Limited to solid or simpler color patterns |

| Production Time | Longer due to pre-dyeing processes | Shorter and more flexible process |

| Cost | Higher due to complex processing | Lower, cost-effective for mass production |

| Application | Used in premium apparel and durable textiles | Common in budget-friendly clothing and home textiles |

| Environmental Impact | Generally lower water usage; eco-friendlier | Higher water consumption in dyeing stage |

Introduction to Polyester Yarn-Dyed and Piece-Dyed Fabrics

Polyester yarn-dyed fabrics are created by dyeing the yarn before weaving or knitting, resulting in vibrant patterns with enhanced colorfastness and durability. In contrast, polyester piece-dyed fabrics undergo dyeing after the fabric is woven, offering uniform color but less intricate designs. Choosing between yarn-dyed and piece-dyed polyester depends on the desired aesthetic, fabric strength, and color precision for specific textile applications.

Overview of Polyester: Properties and Applications

Polyester yarn-dyed fabric, created by dyeing the fibers before weaving, offers superior colorfastness and design precision, ideal for intricate patterns in fashion and home textiles. Polyester piece-dyed fabric, dyed after weaving, provides versatility in solid colors and is commonly used in apparel and upholstery due to its uniform shade and cost-effectiveness. Both processes leverage polyester's durability, wrinkle resistance, moisture-wicking properties, and chemical resilience, supporting applications ranging from activewear to industrial textiles.

What is Yarn-Dyed Polyester?

Yarn-dyed polyester involves coloring the polyester fibers before weaving, resulting in vibrant, long-lasting patterns and designs with enhanced colorfastness. This method allows for precise control of color distribution in the fabric, making it ideal for intricate patterns such as plaids and stripes. Compared to piece-dyed polyester, yarn-dyed polyester offers superior durability and resistance to fading in both apparel and upholstery applications.

What is Piece-Dyed Polyester?

Piece-dyed polyester refers to polyester fabric dyed after the textile has been woven or knitted, allowing for uniform color penetration and versatile dyeing options. This process contrasts with yarn-dyeing, where individual yarns are colored before fabric production, resulting in multi-colored patterns or textures. Piece-dyed polyester offers cost-effectiveness and consistent solid colors, making it ideal for a wide range of apparel and home textile applications.

Key Differences Between Yarn-Dyed and Piece-Dyed Polyester

Yarn-dyed polyester involves coloring the fibers before weaving, resulting in fabrics with vibrant, long-lasting colors and intricate patterns such as plaids and stripes. Piece-dyed polyester is colored after the fabric is woven, offering flexibility for solid colors and large-scale production but with potential color uniformity issues over time. The choice between yarn-dyed and piece-dyed polyester impacts fabric durability, colorfastness, and design complexity.

Color Vibrancy and Fastness Comparison

Polyester yarn-dyed fabrics exhibit superior color vibrancy and fastness compared to piece-dyed polyester due to the dyeing process occurring at the fiber or yarn stage, allowing deeper and more uniform color penetration. Yarn-dyed polyester demonstrates enhanced resistance to fading from washing, sunlight, and abrasion, maintaining color integrity even after extended use. In contrast, piece-dyed polyester fabrics often show less color depth and quicker color loss since the dyeing happens post-fabric production, leading to surface-level color absorption.

Production Process: Yarn-Dyed vs Piece-Dyed Polyester

Yarn-dyed polyester involves dyeing the yarns before weaving or knitting, allowing precise color patterns and increased colorfastness in the final fabric. Piece-dyed polyester refers to the process of dyeing the woven or knitted fabric after production, offering flexibility for quick color changes and uniform color coverage. The yarn-dyeing process ensures enhanced design complexity and durability, while piece-dyeing is more cost-effective for large batches with solid colors.

Advantages and Applications of Yarn-Dyed Polyester

Yarn-dyed polyester offers superior colorfastness and uniformity compared to piece-dyed polyester, making it ideal for high-quality textiles requiring vibrant patterns and durability. Its dyeing process enhances fabric strength and produces intricate designs such as plaids, checks, and stripes widely used in fashion, upholstery, and home textiles. Applications benefit from yarn-dyed polyester's resilience to fading and abrasion, extending product lifespan in demanding environments.

Advantages and Applications of Piece-Dyed Polyester

Piece-dyed polyester offers superior color uniformity and versatility compared to yarn-dyed polyester, making it ideal for a wide range of applications such as fashion apparel, home textiles, and industrial fabrics. The dyeing process allows for vibrant, consistent shades and quick adaptation to seasonal color trends, enhancing fabric creativity and market responsiveness. Its cost-effective production and excellent colorfastness properties ensure durability and value in products requiring large color blocks or intricate patterns.

Choosing Between Polyester Yarn-Dyed and Piece-Dyed Fabrics

Polyester yarn-dyed fabrics offer superior colorfastness and pattern precision by dyeing the yarns before weaving, making them ideal for designs requiring consistent, vibrant hues and durability. Polyester piece-dyed fabrics, dyed after weaving, provide greater flexibility in color changes and are more cost-effective for bulk orders with solid colors. Selecting between yarn-dyed and piece-dyed polyester depends on the importance of design detail, colorfastness, and production budget.

Polyester Yarn-Dyed vs Polyester Piece-Dyed Infographic

materialdif.com

materialdif.com