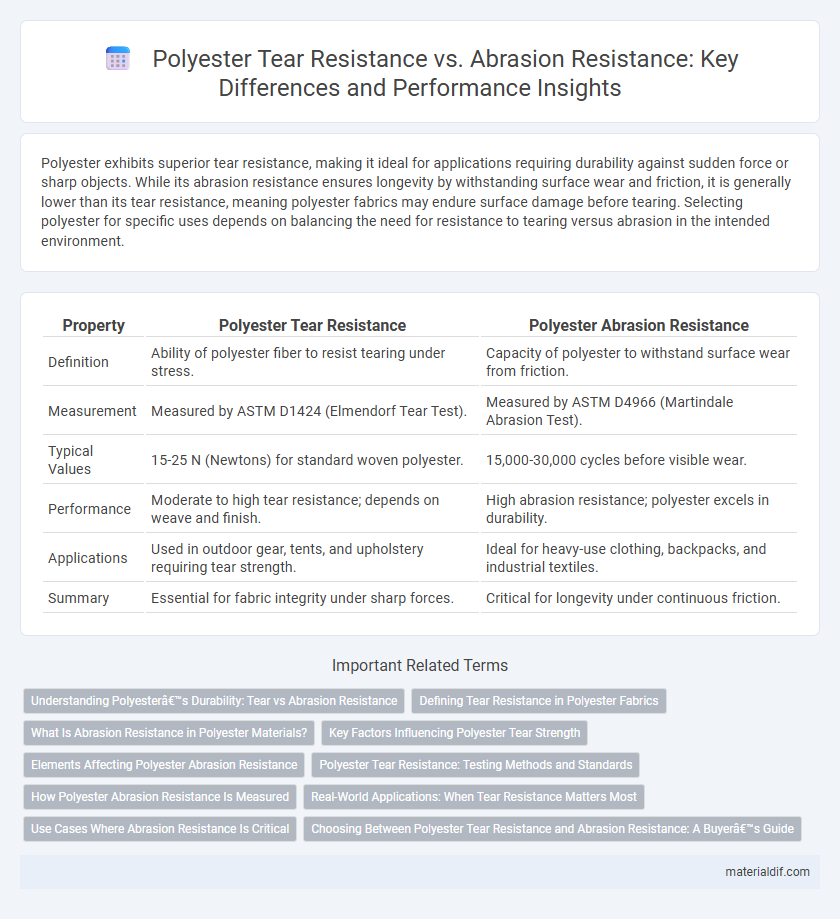

Polyester exhibits superior tear resistance, making it ideal for applications requiring durability against sudden force or sharp objects. While its abrasion resistance ensures longevity by withstanding surface wear and friction, it is generally lower than its tear resistance, meaning polyester fabrics may endure surface damage before tearing. Selecting polyester for specific uses depends on balancing the need for resistance to tearing versus abrasion in the intended environment.

Table of Comparison

| Property | Polyester Tear Resistance | Polyester Abrasion Resistance |

|---|---|---|

| Definition | Ability of polyester fiber to resist tearing under stress. | Capacity of polyester to withstand surface wear from friction. |

| Measurement | Measured by ASTM D1424 (Elmendorf Tear Test). | Measured by ASTM D4966 (Martindale Abrasion Test). |

| Typical Values | 15-25 N (Newtons) for standard woven polyester. | 15,000-30,000 cycles before visible wear. |

| Performance | Moderate to high tear resistance; depends on weave and finish. | High abrasion resistance; polyester excels in durability. |

| Applications | Used in outdoor gear, tents, and upholstery requiring tear strength. | Ideal for heavy-use clothing, backpacks, and industrial textiles. |

| Summary | Essential for fabric integrity under sharp forces. | Critical for longevity under continuous friction. |

Understanding Polyester’s Durability: Tear vs Abrasion Resistance

Polyester exhibits exceptional tear resistance due to its strong molecular structure, which enables it to withstand sudden forces or sharp impacts without ripping easily. Abrasion resistance in polyester is equally impressive, as its smooth fibers reduce friction and prevent surface wear during continuous rubbing or contact with rough surfaces. Understanding these distinct durability properties is critical for selecting polyester materials suited for applications requiring high performance in both tear and abrasion conditions.

Defining Tear Resistance in Polyester Fabrics

Polyester tear resistance refers to the fabric's ability to withstand forces that cause it to rip or split when subjected to sudden stress or sharp objects. This property is critical for applications requiring durability, as it measures how well the polyester fibers maintain integrity under puncture or tearing conditions. Tear resistance is typically evaluated using standardized tests such as the Elmendorf tear test, highlighting polyester's performance in maintaining structural strength under strain compared to its abrasion resistance.

What Is Abrasion Resistance in Polyester Materials?

Abrasion resistance in polyester materials refers to the fabric's ability to withstand surface wear caused by friction or rubbing against other materials, which is critical for maintaining durability in high-contact applications. This property is measured by subjecting polyester fabrics to repeated rubbing tests to evaluate how well they resist damage such as pilling, fiber breakage, or texture changes. Compared to tear resistance, which measures the force required to rip the fabric, abrasion resistance ensures the longevity of polyester textiles used in clothing, upholstery, and industrial uses where continuous friction occurs.

Key Factors Influencing Polyester Tear Strength

Polyester tear resistance depends significantly on fiber structure, weave density, and tensile strength, which determine its ability to withstand sudden force or sharp impacts. Abrasion resistance, by contrast, relates more to surface durability under continuous friction, influenced by fiber finish and fabric construction. Key factors influencing polyester tear strength include fiber orientation, yarn twist, and the presence of reinforcing treatments that enhance tensile integrity.

Elements Affecting Polyester Abrasion Resistance

Polyester abrasion resistance is primarily influenced by fiber denier, weave density, and surface treatment, which determine the fabric's ability to withstand surface wear from friction. Higher fiber denier and tighter weaves enhance durability by reducing fiber breakage during abrasion cycles. Chemical coatings and finishes like silicone or polyurethane also improve abrasion resistance by creating protective barriers that minimize fiber friction and surface degradation.

Polyester Tear Resistance: Testing Methods and Standards

Polyester tear resistance is evaluated using standardized testing methods such as the ASTM D2261 and ISO 4674 protocols, which measure the force required to propagate a tear in woven polyester fabrics. These tests provide critical data for industries reliant on durable fabrics, ensuring materials can withstand mechanical stress and prolong product lifespan. Comparing tear resistance with abrasion resistance highlights polyester's ability to resist damage from both sudden force and repetitive surface rubbing, guiding its application in protective clothing and upholstery.

How Polyester Abrasion Resistance Is Measured

Polyester abrasion resistance is measured using standardized tests such as the Martindale Abrasion Test and the Wyzenbeek Test, which evaluate the fabric's ability to withstand surface wear from friction. These tests involve subjecting the polyester material to repetitive rubbing cycles until visible wear or thread breakage occurs, providing quantifiable data on durability. In comparison, tear resistance measures the force required to propagate a tear, focusing on the material's ability to resist rupture rather than surface wear.

Real-World Applications: When Tear Resistance Matters Most

Polyester's tear resistance is critical in applications like outdoor gear and safety harnesses, where the fabric must withstand sudden, forceful impacts without ripping. Abrasion resistance is key for products such as upholstery and automotive interiors that endure constant friction and surface wear. Understanding the difference ensures optimal material selection, enhancing durability and performance in specific real-world environments.

Use Cases Where Abrasion Resistance Is Critical

Polyester's abrasion resistance is crucial in applications such as outdoor gear, upholstery, and industrial fabrics where surfaces face repeated friction and wear. In these use cases, polyester fibers maintain structural integrity and aesthetic appeal better than relying solely on tear resistance, which measures resistance to sudden forces rather than ongoing surface damage. High abrasion resistance ensures longer lifespan and durability in products like backpacks, workwear, and automotive seating, where persistent rubbing and scraping can quickly degrade materials.

Choosing Between Polyester Tear Resistance and Abrasion Resistance: A Buyer’s Guide

Polyester tear resistance measures the fabric's ability to withstand force without ripping, making it ideal for applications requiring durability against sharp impacts. Polyester abrasion resistance evaluates how well the material endures surface wear from friction, crucial for products exposed to continuous rubbing or scraping. Buyers should assess their specific use cases--such as outdoor gear favoring tear resistance or upholstery demanding abrasion resistance--to select the optimal polyester type for enhanced longevity.

Polyester Tear Resistance vs Polyester Abrasion Resistance Infographic

materialdif.com

materialdif.com