Polyester resilience refers to the fabric's ability to recover its shape after being stretched, ensuring durability and long-lasting wear. Polyester elasticity describes how much the fabric can stretch under tension before returning to its original form, contributing to comfort and flexibility. The balance between resilience and elasticity in polyester materials determines their suitability for applications requiring both strength and stretchability.

Table of Comparison

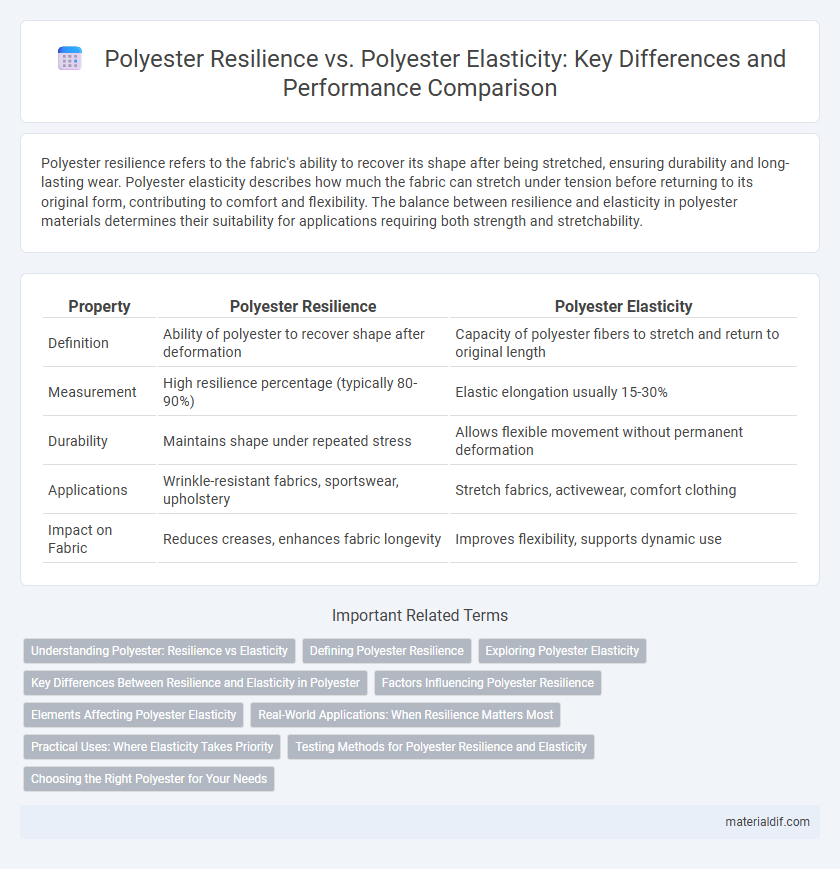

| Property | Polyester Resilience | Polyester Elasticity |

|---|---|---|

| Definition | Ability of polyester to recover shape after deformation | Capacity of polyester fibers to stretch and return to original length |

| Measurement | High resilience percentage (typically 80-90%) | Elastic elongation usually 15-30% |

| Durability | Maintains shape under repeated stress | Allows flexible movement without permanent deformation |

| Applications | Wrinkle-resistant fabrics, sportswear, upholstery | Stretch fabrics, activewear, comfort clothing |

| Impact on Fabric | Reduces creases, enhances fabric longevity | Improves flexibility, supports dynamic use |

Understanding Polyester: Resilience vs Elasticity

Polyester exhibits high resilience, allowing it to recover its original shape quickly after stretching or bending, making it ideal for durable fabrics. Its elasticity, though moderate compared to natural fibers like rubber, enables sufficient stretch and flexibility without permanent deformation. Understanding the balance between polyester's resilience and elasticity helps manufacturers design textiles that maintain shape while providing comfort and durability.

Defining Polyester Resilience

Polyester resilience refers to the fiber's ability to recover its original shape and resist deformation after being stretched or compressed, making it highly durable in various applications. This property enables polyester fabrics to maintain their structural integrity and appearance even after repeated wear or washing. Unlike elasticity, which measures the extent of stretch, resilience emphasizes the material's capacity to bounce back without permanent distortion.

Exploring Polyester Elasticity

Polyester elasticity refers to the fiber's ability to stretch and recover its original shape, making it highly flexible and resistant to deformation. This characteristic enhances the comfort and durability of polyester textiles, particularly in activewear and sports apparel. Its excellent elasticity distinguishes it from resilience, which primarily concerns the fabric's capacity to withstand physical stresses without permanent damage.

Key Differences Between Resilience and Elasticity in Polyester

Polyester resilience refers to the fabric's ability to recover its shape after deformation, resisting wrinkles and creases, while polyester elasticity measures the material's capacity to stretch and return to its original length. Resilience in polyester enhances durability and appearance retention, making it ideal for wrinkle-resistant clothing and upholstery. Elasticity impacts comfort and fit, crucial for activewear and stretchable garments, highlighting distinct functional properties within polyester fibers.

Factors Influencing Polyester Resilience

Polyester resilience primarily depends on molecular structure, crystallinity, and fiber orientation, which determine its ability to recover shape after deformation. High crystallinity enhances dimensional stability, while molecular alignment affects tensile strength and resistance to permanent set. Environmental factors such as temperature and humidity also influence polyester's resilience by altering polymer chain mobility.

Elements Affecting Polyester Elasticity

Polyester elasticity is primarily influenced by molecular structure, including the degree of polymerization and the presence of flexible segments within the polymer chains. Temperature and external stress impact the movement of polymer chains, affecting elasticity performance under various conditions. Additives and fiber processing methods also play significant roles in enhancing or reducing the elasticity of polyester fibers.

Real-World Applications: When Resilience Matters Most

Polyester resilience, defined by its ability to recover from deformation without permanent damage, is critical in high-impact applications such as industrial workwear and outdoor gear where durability and shape retention are essential. In contrast, polyester elasticity, which measures stretchability and recovery, plays a secondary role in settings that require flexibility but less frequent stress recovery, for example in casual clothing and sportswear. Real-world applications prioritize resilience to ensure long-term performance and structural integrity under repeated mechanical stress and harsh environmental conditions.

Practical Uses: Where Elasticity Takes Priority

Polyester elasticity is crucial in practical applications requiring stretch and recovery, such as activewear, swimwear, and performance textiles, where flexibility enhances comfort and movement. In contrast, polyester resilience, which refers to the fabric's ability to resist wear and maintain shape over time, is prioritized in upholstery, outerwear, and industrial fabrics. Elasticity outweighs resilience in garments demanding stretch, ensuring durability without compromising fit or flexibility.

Testing Methods for Polyester Resilience and Elasticity

Testing methods for polyester resilience typically involve cyclic compression and recovery tests to measure its ability to regain shape after deformation, utilizing instruments like dynamic mechanical analyzers (DMA) for precise stress-strain data. Elasticity assessments focus on tensile testing with universal testing machines (UTM), where elongation at break and elastic modulus are quantified to evaluate the fiber's stretch and recovery capabilities. Advanced testing protocols integrate both resilience and elasticity metrics to optimize polyester performance in textiles and industrial applications.

Choosing the Right Polyester for Your Needs

Polyester resilience refers to the fiber's ability to resist wrinkles, shrinking, and stretching, making it ideal for durable and easy-care garments. Polyester elasticity, on the other hand, measures the fiber's capacity to stretch and return to its original shape, which is crucial for activewear and fitted clothing requiring flexibility. Choosing the right polyester depends on whether durability or stretchability is prioritized, with high-resilience polyester suited for outerwear and high-elasticity polyester better for sportswear and form-fitting designs.

Polyester Resilience vs Polyester Elasticity Infographic

materialdif.com

materialdif.com