Sublimation printing on polyester offers vibrant, long-lasting colors by infusing ink directly into the fabric fibers, resulting in a soft, breathable finish that won't crack or peel. Screen printing, while effective for bold designs, often sits on top of polyester fibers and may lead to stiffness or cracking over time, especially on stretchy fabrics. For polyester materials, sublimation printing provides superior durability and color vibrancy compared to traditional screen printing methods.

Table of Comparison

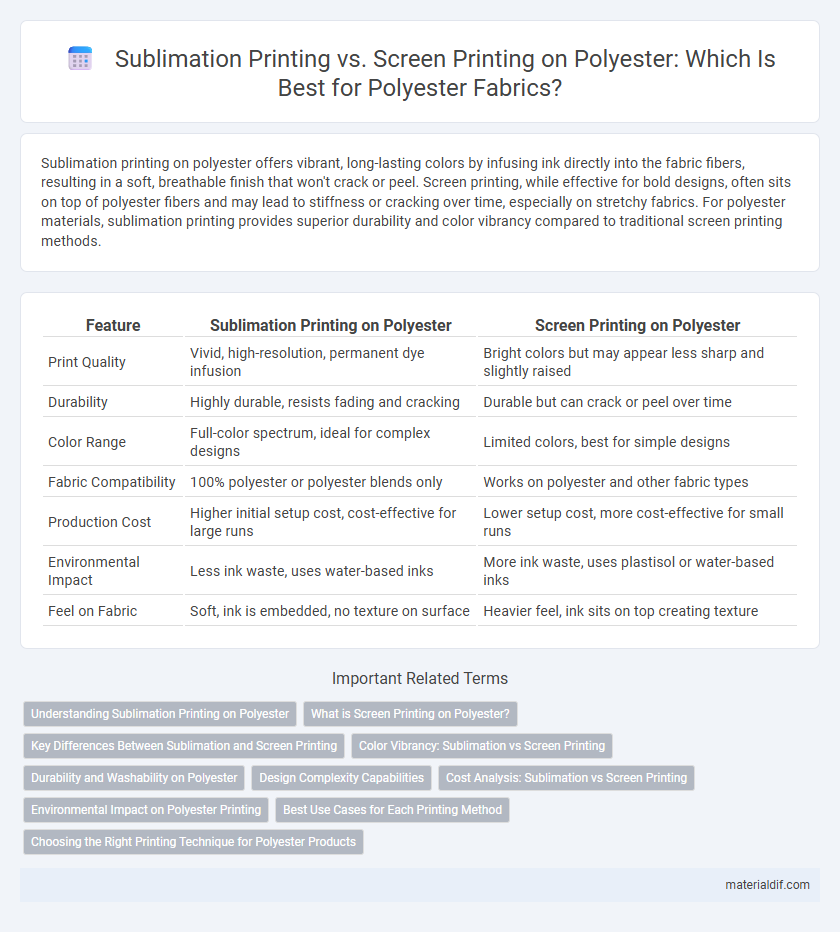

| Feature | Sublimation Printing on Polyester | Screen Printing on Polyester |

|---|---|---|

| Print Quality | Vivid, high-resolution, permanent dye infusion | Bright colors but may appear less sharp and slightly raised |

| Durability | Highly durable, resists fading and cracking | Durable but can crack or peel over time |

| Color Range | Full-color spectrum, ideal for complex designs | Limited colors, best for simple designs |

| Fabric Compatibility | 100% polyester or polyester blends only | Works on polyester and other fabric types |

| Production Cost | Higher initial setup cost, cost-effective for large runs | Lower setup cost, more cost-effective for small runs |

| Environmental Impact | Less ink waste, uses water-based inks | More ink waste, uses plastisol or water-based inks |

| Feel on Fabric | Soft, ink is embedded, no texture on surface | Heavier feel, ink sits on top creating texture |

Understanding Sublimation Printing on Polyester

Sublimation printing on polyester involves transferring dye onto the fabric using heat, resulting in vibrant, long-lasting colors that penetrate the fibers rather than sitting on the surface. This method excels in maintaining the fabric's breathability and softness, making it ideal for polyester sportswear and activewear. Polyester's synthetic composition allows sublimation dyes to bond permanently, preventing fading and cracking compared to traditional screen printing.

What is Screen Printing on Polyester?

Screen printing on polyester involves applying ink through a stencil or mesh screen directly onto the fabric, creating vibrant, durable designs. This process uses plastisol or water-based inks that adhere well to polyester fibers, offering excellent color opacity and wash resistance. Compared to sublimation, screen printing is ideal for bold, solid-color graphics and is cost-effective for larger production runs on polyester garments.

Key Differences Between Sublimation and Screen Printing

Sublimation printing on polyester uses heat to infuse dye directly into the fabric, resulting in vibrant, durable, and breathable prints that do not crack or fade. Screen printing applies layers of ink on the fabric's surface, producing bold colors but with less flexibility and potential for ink buildup on polyester, which can affect texture and breathability. Sublimation is ideal for all-over, detailed designs on light-colored polyester, while screen printing excels in solid, sharp graphics on various polyester blends and darker fabrics.

Color Vibrancy: Sublimation vs Screen Printing

Sublimation printing on polyester produces exceptional color vibrancy by infusing dye directly into the fabric fibers, resulting in bright, long-lasting hues that resist fading and cracking. Screen printing applies ink on the surface of polyester, offering strong color opacity but often lacks the same depth and durability of sublimation, especially on lighter fabrics. For vivid, durable prints with continuous color gradients and sharp details on polyester, sublimation printing is typically superior to screen printing.

Durability and Washability on Polyester

Sublimation printing on polyester offers superior durability and washability due to the dye's ability to bond directly with the fabric fibers, resulting in vibrant colors that do not fade or crack over time. Screen printing applies ink on the surface, which can lead to cracking and peeling after multiple washes, especially on polyester blends. The chemical integration of sublimation ink into polyester fibers ensures long-lasting print quality ideal for high-performance and sportswear applications.

Design Complexity Capabilities

Sublimation printing offers superior design complexity capabilities on polyester, enabling vibrant, full-color, and intricate patterns that penetrate the fabric for long-lasting durability. Screen printing, while effective for bold and simple designs, struggles with fine detail and color gradients due to ink layering limitations on polyester. For detailed, multicolor imagery, sublimation printing remains the preferred choice, maximizing design precision and fabric integration.

Cost Analysis: Sublimation vs Screen Printing

Sublimation printing on polyester offers lower long-term costs due to minimal setup fees and the ability to produce vibrant, full-color designs without additional charges per color. Screen printing involves higher initial costs from creating screens for each color and is more cost-effective only in large volume runs, especially with fewer colors. For small to medium orders with complex or multi-color designs, sublimation printing provides a more economical and efficient solution on polyester fabrics.

Environmental Impact on Polyester Printing

Sublimation printing on polyester uses water-based inks that bond directly with polyester fibers, resulting in minimal waste and lower emissions compared to screen printing, which involves plastisol inks and generates significant chemical runoff and non-biodegradable waste. This digital process eliminates excess ink usage and reduces energy consumption, enhancing sustainability in polyester textile production. Screen printing on polyester often requires multiple cleanup steps and higher chemical input, leading to a greater environmental footprint in both water pollution and resource utilization.

Best Use Cases for Each Printing Method

Sublimation printing on polyester excels in producing vibrant, full-color designs with high durability, making it ideal for sportswear, custom apparel, and promotional items requiring detailed graphics. Screen printing offers superior opacity and cost-effectiveness for large orders, best suited for bold logos and simple designs on polyester fabric. Choosing between sublimation and screen printing depends on design complexity, order volume, and end-use requirements.

Choosing the Right Printing Technique for Polyester Products

Sublimation printing offers vibrant, long-lasting colors by infusing ink directly into polyester fibers, making it ideal for lightweight and stretchy polyester fabrics used in sportswear and fashion. Screen printing creates bold, opaque designs with excellent durability, better suited for heavier polyester garments and bulk orders due to lower per-unit costs. Selecting between sublimation and screen printing depends on fabric type, design complexity, color vibrancy needs, and production volume for optimal results on polyester products.

Sublimation Printing vs Screen Printing (on Polyester) Infographic

materialdif.com

materialdif.com