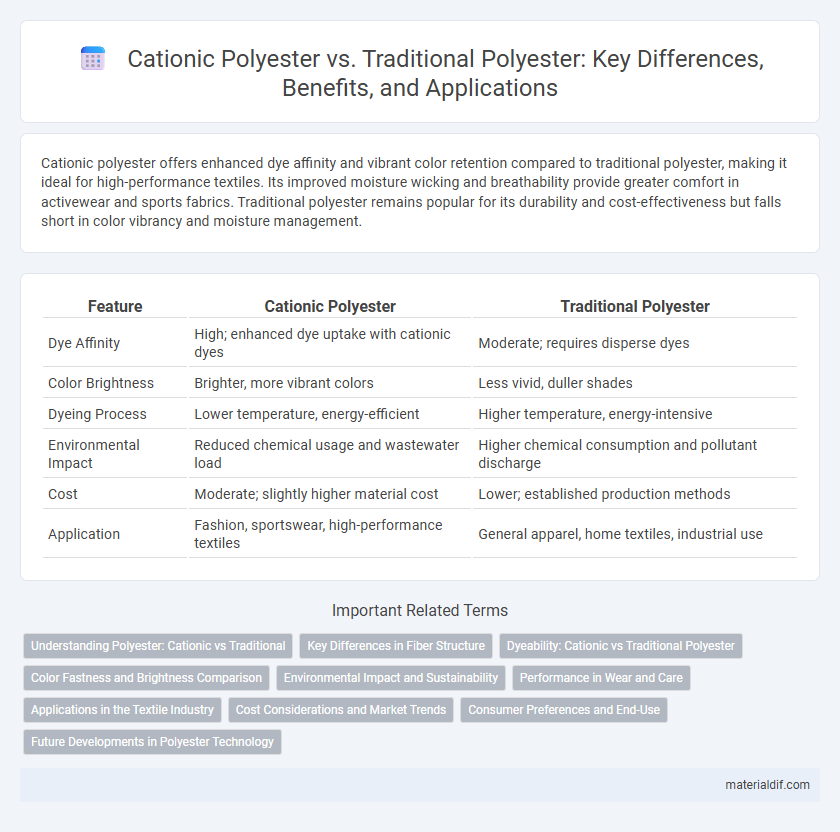

Cationic polyester offers enhanced dye affinity and vibrant color retention compared to traditional polyester, making it ideal for high-performance textiles. Its improved moisture wicking and breathability provide greater comfort in activewear and sports fabrics. Traditional polyester remains popular for its durability and cost-effectiveness but falls short in color vibrancy and moisture management.

Table of Comparison

| Feature | Cationic Polyester | Traditional Polyester |

|---|---|---|

| Dye Affinity | High; enhanced dye uptake with cationic dyes | Moderate; requires disperse dyes |

| Color Brightness | Brighter, more vibrant colors | Less vivid, duller shades |

| Dyeing Process | Lower temperature, energy-efficient | Higher temperature, energy-intensive |

| Environmental Impact | Reduced chemical usage and wastewater load | Higher chemical consumption and pollutant discharge |

| Cost | Moderate; slightly higher material cost | Lower; established production methods |

| Application | Fashion, sportswear, high-performance textiles | General apparel, home textiles, industrial use |

Understanding Polyester: Cationic vs Traditional

Cationic polyester incorporates positively charged ions during polymerization, enhancing dye affinity and enabling vibrant, long-lasting colors compared to traditional polyester, which often requires additional treatments for colorfastness. Unlike traditional polyester, cationic fibers exhibit improved moisture wicking and dye absorption, leading to superior fabric performance in activewear and textile applications. This advanced polyester variant reduces environmental impact by minimizing the need for harsh chemical dyes and wastewater in the dyeing process.

Key Differences in Fiber Structure

Cationic polyester fibers exhibit a unique fiber structure characterized by the incorporation of positively charged ions, enhancing dye affinity and colorfastness compared to traditional polyester. Traditional polyester fibers possess a more uniform and hydrophobic molecular arrangement, which limits dye uptake and requires additional chemical treatments for coloration. These structural differences directly impact the performance and applications of each polyester type in textile manufacturing.

Dyeability: Cationic vs Traditional Polyester

Cationic polyester fibers exhibit superior dyeability compared to traditional polyester, allowing for more vibrant and uniform coloration using disperse dyes. Unlike traditional polyester, cationic polyester contains positively charged sites that enhance the affinity for anionic dyes, resulting in enhanced color fastness and reduced energy consumption during the dyeing process. This improved dyeability makes cationic polyester a preferred choice for applications requiring high-quality, sustainable textile coloration.

Color Fastness and Brightness Comparison

Cationic polyester fibers exhibit superior color fastness compared to traditional polyester due to their enhanced dye affinity, resulting in more vibrant and long-lasting colors. The unique cationic dye sites within cationic polyester promote brighter and more vivid coloration, maintaining intensity even after multiple washes. Traditional polyester, relying on disperse dyes, often shows duller hues and diminished brightness over time, reflecting lower resistance to fading and color bleeding.

Environmental Impact and Sustainability

Cationic polyester exhibits enhanced environmental benefits compared to traditional polyester due to its lower energy consumption during dyeing processes and reduced chemical usage, contributing to decreased water pollution. The modification in cationic polyester fibers enables superior dye affinity, which reduces the need for harmful mordants and lessens overall ecological footprint. Sustainable production practices involving cationic polyester support a circular economy by facilitating easier recycling and minimizing microplastic release into ecosystems.

Performance in Wear and Care

Cationic polyester offers superior performance in wear resistance and care compared to traditional polyester, featuring enhanced dye uptake that results in vibrant colors and reduced fading over time. Its moisture-wicking properties improve comfort and reduce pilling, extending garment lifespan. Care-wise, cationic polyester requires lower washing temperatures and resists shrinkage, maintaining fabric integrity longer than conventional polyester.

Applications in the Textile Industry

Cationic polyester fibers exhibit enhanced dye affinity and faster coloration rates compared to traditional polyester, making them ideal for high-quality textile applications requiring vibrant, long-lasting colors. These fibers are extensively used in sportswear, fashion apparel, and home textiles due to their improved moisture management and comfort properties. Traditional polyester remains prevalent in industrial fabrics and budget-friendly clothing, offering durability and ease of care but with less vibrant dye uptake.

Cost Considerations and Market Trends

Cationic polyester offers enhanced dye affinity and faster processing times, which can reduce production costs compared to traditional polyester, known for higher energy consumption due to its dyeing process. Market trends reveal increasing demand for cationic polyester in performance and sustainable textile segments, driven by manufacturers aiming to capitalize on its eco-friendly and cost-efficient advantages. Price sensitivity remains critical as traditional polyester maintains dominance due to established supply chains and lower raw material costs.

Consumer Preferences and End-Use

Cationic polyester offers enhanced dye uptake and vibrant colorfastness compared to traditional polyester, aligning with consumer preferences for brighter and longer-lasting textiles. End-users favor cationic polyester in activewear and fashion garments due to its superior comfort, moisture management, and environmental benefits. Traditional polyester remains popular for durable, cost-effective applications such as upholstery and industrial fabrics where color intensity is less critical.

Future Developments in Polyester Technology

Cationic polyester offers advanced dyeability and moisture management compared to traditional polyester, driving innovations in textile performance. Future developments in polyester technology emphasize sustainable production methods, including bio-based monomers and eco-friendly catalysts that reduce environmental impact. Enhanced fiber modification techniques aim to improve fabric functionality, such as increased breathability and antimicrobial properties, positioning cationic polyester as a key material in next-generation textiles.

Cationic Polyester vs Traditional Polyester Infographic

materialdif.com

materialdif.com