Polyester coating offers superior breathability and flexibility compared to PVC coating, making it ideal for applications requiring durability with lightweight characteristics. PVC coating provides excellent waterproofing and chemical resistance, suited for environments exposed to harsh weather and industrial conditions. Choosing between polyester and PVC coatings depends on balancing the need for breathability versus enhanced protection and longevity.

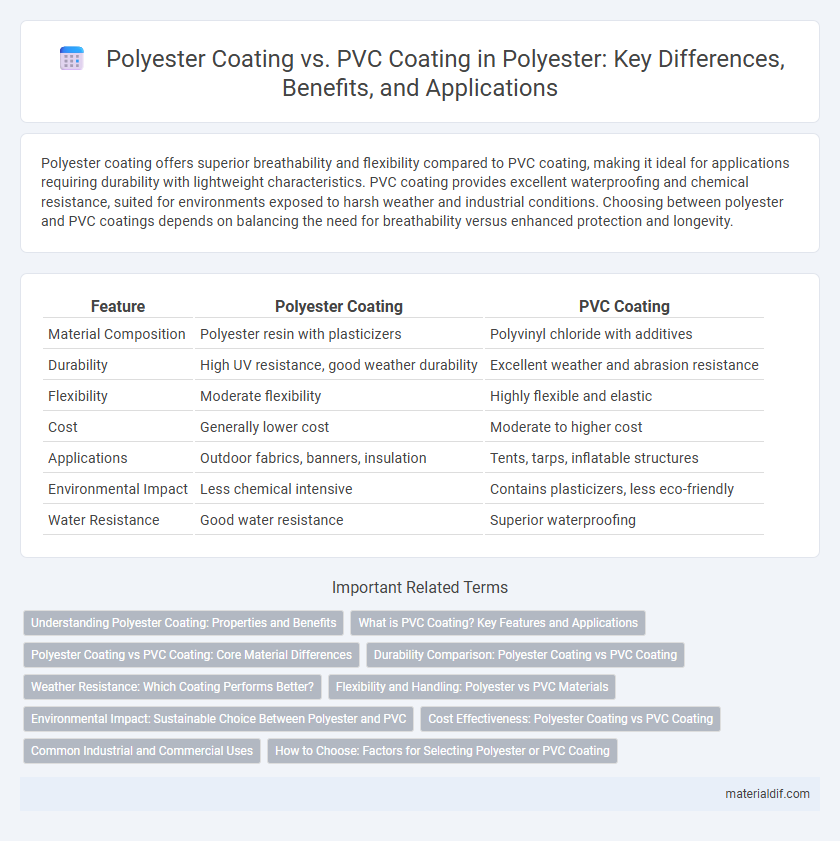

Table of Comparison

| Feature | Polyester Coating | PVC Coating |

|---|---|---|

| Material Composition | Polyester resin with plasticizers | Polyvinyl chloride with additives |

| Durability | High UV resistance, good weather durability | Excellent weather and abrasion resistance |

| Flexibility | Moderate flexibility | Highly flexible and elastic |

| Cost | Generally lower cost | Moderate to higher cost |

| Applications | Outdoor fabrics, banners, insulation | Tents, tarps, inflatable structures |

| Environmental Impact | Less chemical intensive | Contains plasticizers, less eco-friendly |

| Water Resistance | Good water resistance | Superior waterproofing |

Understanding Polyester Coating: Properties and Benefits

Polyester coating offers excellent durability, UV resistance, and weatherproofing, making it ideal for outdoor applications and long-term performance. It provides a smooth, aesthetically pleasing finish with strong adhesion to metal surfaces, enhancing corrosion resistance. Compared to PVC coating, polyester coating is lighter, more environmentally friendly, and retains color vibrancy over time without yellowing.

What is PVC Coating? Key Features and Applications

PVC coating is a plasticized polymer applied to fabrics to enhance durability, water resistance, and flexibility, commonly used in outdoor applications. It offers excellent weather resistance, UV protection, and chemical resistance, making it ideal for tarpaulins, inflatable structures, and protective covers. The coating provides a smooth, glossy finish and superior adhesion to polyester fabric, ensuring long-lasting performance in harsh environments.

Polyester Coating vs PVC Coating: Core Material Differences

Polyester coating is made from polyethylene terephthalate, offering superior UV resistance, durability, and color retention compared to PVC coating, which consists of polyvinyl chloride and often contains plasticizers that can degrade over time. Polyester coatings exhibit higher tensile strength and environmental resistance, making them ideal for outdoor applications, while PVC coatings provide greater flexibility and chemical resistance but are more prone to cracking and fading. The core material differences impact the performance and longevity of coated fabrics, with polyester coatings generally favored for longer-lasting, weather-resistant uses.

Durability Comparison: Polyester Coating vs PVC Coating

Polyester coating offers superior UV resistance and higher temperature tolerance compared to PVC coating, making it more durable for outdoor applications. PVC coating provides excellent flexibility and chemical resistance but tends to degrade faster under prolonged sun exposure and extreme weather conditions. The choice between polyester and PVC coatings depends on specific durability requirements, with polyester favored for long-term structural integrity.

Weather Resistance: Which Coating Performs Better?

Polyester coating offers superior weather resistance due to its excellent UV stability and ability to withstand extreme temperature variations without degrading. PVC coating, while providing good water resistance, tends to become brittle and crack under prolonged exposure to sunlight and harsh weather conditions. Consequently, polyester coatings are generally preferred for outdoor applications requiring long-term durability and protection against environmental elements.

Flexibility and Handling: Polyester vs PVC Materials

Polyester coatings offer superior flexibility and ease of handling compared to PVC coatings, making them ideal for applications requiring frequent bending and manipulation. The inherent elasticity of polyester fibers allows the material to maintain its integrity under stress, whereas PVC coatings tend to be stiffer and prone to cracking over time. This enhanced flexibility in polyester results in longer-lasting performance in dynamic environments such as outdoor banners and flexible fabrics.

Environmental Impact: Sustainable Choice Between Polyester and PVC

Polyester coating offers a more sustainable option compared to PVC coating due to its lower environmental toxicity and better recyclability. Unlike PVC, polyester coatings do not release harmful dioxins or chlorine-based compounds during production or disposal, significantly reducing ecological damage. Choosing polyester coating supports eco-friendly manufacturing practices and aligns with increased demand for greener industrial materials.

Cost Effectiveness: Polyester Coating vs PVC Coating

Polyester coating typically offers greater cost effectiveness compared to PVC coating due to its longer lifespan and superior resistance to UV exposure, reducing maintenance and replacement expenses. While PVC coatings may have lower initial costs, their susceptibility to cracking and fading often results in higher long-term costs. Businesses looking for durable and economical protective solutions often prefer polyester coatings to maximize value.

Common Industrial and Commercial Uses

Polyester coating is widely used in industrial applications for its excellent durability, UV resistance, and corrosion protection, making it ideal for automotive parts, metal roofing, and electrical insulation. PVC coating is favored in commercial settings due to its flexibility, chemical resistance, and waterproofing qualities, commonly applied in tarpaulins, inflatable structures, and conveyor belts. Both coatings serve critical roles in protecting and extending the lifespan of materials across diverse industries.

How to Choose: Factors for Selecting Polyester or PVC Coating

Selecting between polyester and PVC coatings depends on factors such as durability, environmental exposure, and cost efficiency. Polyester coatings offer excellent UV resistance and color retention, making them ideal for outdoor applications with prolonged sun exposure. PVC coatings provide superior flexibility and chemical resistance, suited for environments requiring enhanced waterproofing and abrasion protection.

Polyester Coating vs PVC Coating Infographic

materialdif.com

materialdif.com