Thermoplastic polyester softens when heated and can be reshaped multiple times without significant chemical change, making it ideal for recycling and remolding applications. Thermoset polyester undergoes a chemical curing process that creates a rigid, cross-linked structure, providing superior heat resistance and mechanical strength but making it impossible to remelt or reshape after curing. These fundamental differences dictate the selection of polyester types in industries requiring flexibility or durability under thermal stress.

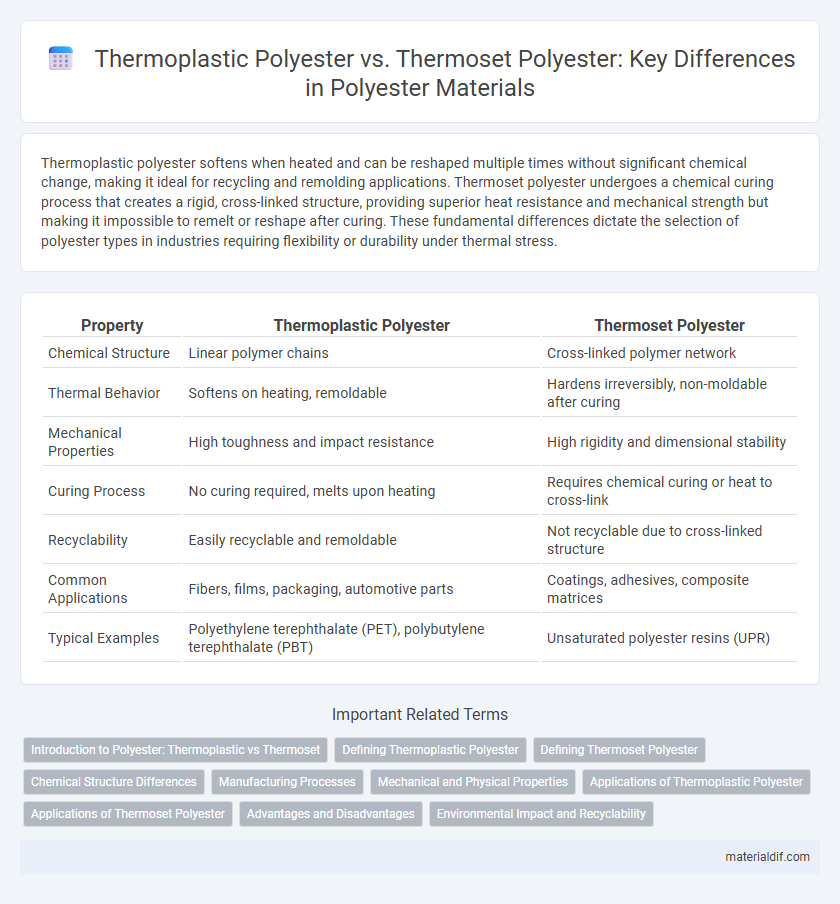

Table of Comparison

| Property | Thermoplastic Polyester | Thermoset Polyester |

|---|---|---|

| Chemical Structure | Linear polymer chains | Cross-linked polymer network |

| Thermal Behavior | Softens on heating, remoldable | Hardens irreversibly, non-moldable after curing |

| Mechanical Properties | High toughness and impact resistance | High rigidity and dimensional stability |

| Curing Process | No curing required, melts upon heating | Requires chemical curing or heat to cross-link |

| Recyclability | Easily recyclable and remoldable | Not recyclable due to cross-linked structure |

| Common Applications | Fibers, films, packaging, automotive parts | Coatings, adhesives, composite matrices |

| Typical Examples | Polyethylene terephthalate (PET), polybutylene terephthalate (PBT) | Unsaturated polyester resins (UPR) |

Introduction to Polyester: Thermoplastic vs Thermoset

Thermoplastic polyester, known for its ability to be repeatedly melted and reshaped, is primarily used in fibers, films, and packaging due to its recyclability and flexibility. Thermoset polyester, in contrast, undergoes a curing process that creates a cross-linked, rigid structure, making it ideal for durable composites and coatings with high thermal stability. Understanding the molecular differences between thermoplastic and thermoset polyesters is essential for selecting the appropriate material for industrial applications such as automotive parts and electronic enclosures.

Defining Thermoplastic Polyester

Thermoplastic polyester is a type of polyester that softens when heated and hardens upon cooling, allowing it to be reshaped multiple times without altering its chemical structure. Common examples include polyethylene terephthalate (PET), widely used in fibers and packaging due to its recyclability and durability. Its reversible physical changes make thermoplastic polyester ideal for applications requiring molding, extrusion, and recycling, distinguishing it from thermoset polyester which forms irreversible cross-linked structures.

Defining Thermoset Polyester

Thermoset polyester is a type of polyester resin that undergoes a chemical curing process, forming a rigid, cross-linked molecular structure that cannot be remelted or reshaped. Unlike thermoplastic polyester, which softens upon heating and can be remolded, thermoset polyester offers superior chemical resistance, mechanical strength, and thermal stability due to its irreversible hardening. This makes thermoset polyester ideal for applications requiring durable, heat-resistant materials such as coatings, adhesives, and composite matrices.

Chemical Structure Differences

Thermoplastic polyester consists of linear or slightly branched polymer chains, allowing it to soften and reshape upon heating due to reversible intermolecular forces. Thermoset polyester features a highly cross-linked three-dimensional network formed through irreversible covalent bonds, which prevents melting and provides enhanced thermal stability. These chemical structure differences determine their distinct processing methods and mechanical properties in applications.

Manufacturing Processes

Thermoplastic polyester is manufactured through a melt processing technique, allowing it to be repeatedly heated and reshaped, typically using extrusion or injection molding methods. Thermoset polyester undergoes a curing process involving chemical cross-linking during molding, resulting in a rigid, permanently set structure that cannot be remelted or reshaped. The manufacturing of thermoplastic polyester emphasizes recyclability and versatility, whereas thermoset polyester focuses on durability and thermal stability through irreversible chemical reactions.

Mechanical and Physical Properties

Thermoplastic polyester exhibits high impact resistance, excellent flexibility, and superior melt-processability, allowing it to be reshaped multiple times without altering its mechanical properties. In contrast, thermoset polyester has a rigid, cross-linked polymer structure that provides exceptional dimensional stability, high heat resistance, and superior chemical resistance but lacks the ability to be remelted or reprocessed. Mechanical strength in thermoplastic polyester is generally lower than thermoset variants, while thermoset polyester delivers higher tensile strength and stiffness due to its permanent network structure.

Applications of Thermoplastic Polyester

Thermoplastic polyester is widely used in automotive parts, electrical components, and packaging due to its excellent chemical resistance, high tensile strength, and recyclability. Its ability to be repeatedly melted and reshaped makes it ideal for injection molding and extrusion processes in manufacturing flexible films, fibers, and plastic containers. Compared to thermoset polyester, thermoplastic variants offer superior versatility in applications requiring durability combined with ease of processing.

Applications of Thermoset Polyester

Thermoset polyester is widely used in applications requiring high thermal stability and chemical resistance, such as electrical insulation, automotive parts, and corrosion-resistant coatings. Its cross-linked molecular structure provides superior mechanical strength, making it ideal for manufacturing durable composites and molded components in aerospace and marine industries. Industrial applications also include adhesives and laminates due to its excellent dimensional stability and resistance to deformation under stress.

Advantages and Disadvantages

Thermoplastic polyester offers advantages such as recyclability, ease of reshaping, and high impact resistance, making it suitable for applications requiring durability and flexibility. Thermoset polyester provides superior heat resistance, chemical stability, and dimensional rigidity but is non-recyclable and prone to brittleness after curing. The choice between thermoplastic and thermoset polyester depends on specific needs for reprocessing capabilities versus thermal and mechanical strength.

Environmental Impact and Recyclability

Thermoplastic polyester can be melted and remolded multiple times, making it highly recyclable and reducing environmental waste. Thermoset polyester, due to its cross-linked molecular structure, is not recyclable through remelting processes and typically ends up in landfills or requires energy-intensive chemical recycling methods. The lower recyclability of thermoset polyester contributes to higher environmental impact compared to the more sustainable, recyclable thermoplastic polyester.

Thermoplastic Polyester vs Thermoset Polyester Infographic

materialdif.com

materialdif.com