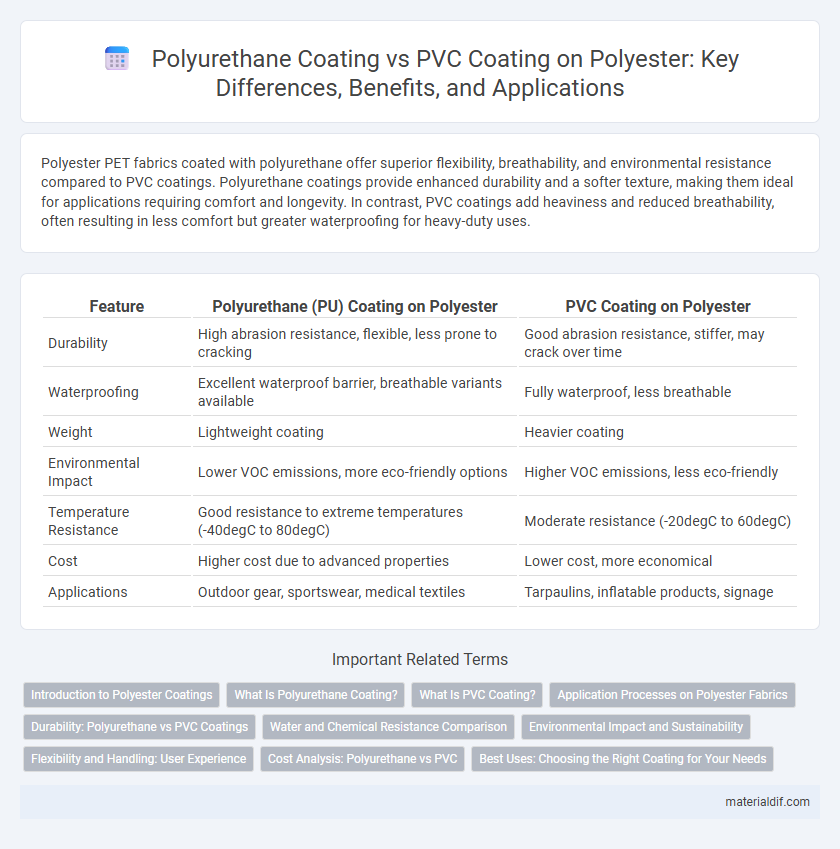

Polyester PET fabrics coated with polyurethane offer superior flexibility, breathability, and environmental resistance compared to PVC coatings. Polyurethane coatings provide enhanced durability and a softer texture, making them ideal for applications requiring comfort and longevity. In contrast, PVC coatings add heaviness and reduced breathability, often resulting in less comfort but greater waterproofing for heavy-duty uses.

Table of Comparison

| Feature | Polyurethane (PU) Coating on Polyester | PVC Coating on Polyester |

|---|---|---|

| Durability | High abrasion resistance, flexible, less prone to cracking | Good abrasion resistance, stiffer, may crack over time |

| Waterproofing | Excellent waterproof barrier, breathable variants available | Fully waterproof, less breathable |

| Weight | Lightweight coating | Heavier coating |

| Environmental Impact | Lower VOC emissions, more eco-friendly options | Higher VOC emissions, less eco-friendly |

| Temperature Resistance | Good resistance to extreme temperatures (-40degC to 80degC) | Moderate resistance (-20degC to 60degC) |

| Cost | Higher cost due to advanced properties | Lower cost, more economical |

| Applications | Outdoor gear, sportswear, medical textiles | Tarpaulins, inflatable products, signage |

Introduction to Polyester Coatings

Polyester coatings enhance fabric durability, stain resistance, and water repellency, with polyurethane (PU) and polyvinyl chloride (PVC) being prominent choices. Polyurethane coatings provide superior flexibility, abrasion resistance, and environmental friendliness compared to PVC coatings, which offer excellent waterproofing and cost-effectiveness but are less eco-friendly and more rigid. Selection between PU and PVC coatings depends on end-use requirements such as flexibility, durability, environmental impact, and budget constraints.

What Is Polyurethane Coating?

Polyurethane coating on polyester provides a durable, flexible, and abrasion-resistant finish that enhances water repellency and UV protection. This coating forms a breathable layer, allowing moisture vapor to escape while preventing water ingress, making it ideal for outdoor and active wear applications. Compared to PVC coating, polyurethane is lighter, more elastic, and environmentally friendly, offering superior comfort and longevity for polyester textiles.

What Is PVC Coating?

PVC coating on polyester fabric involves applying a layer of polyvinyl chloride to enhance durability, water resistance, and flexibility. This coating creates a robust barrier against environmental factors such as moisture, UV rays, and abrasion, making it ideal for outdoor applications like tents, tarps, and awnings. PVC-coated polyester stands out for its strong chemical resistance and ease of cleaning compared to polyurethane coatings.

Application Processes on Polyester Fabrics

Polyurethane coating on polyester fabrics offers a flexible, breathable, and durable finish achieved through a wet coating process that ensures uniform application and strong adhesion, ideal for outdoor gear and medical textiles. PVC coating is applied via a calendering or knife-over-roll method, creating a heavier, waterproof layer suitable for industrial tarps, inflatables, and marine fabrics. The choice of coating process significantly impacts the fabric's weight, flexibility, and resistance properties, tailoring the polyester material to specific end-use requirements.

Durability: Polyurethane vs PVC Coatings

Polyurethane coatings on polyester fabrics offer superior durability, providing excellent abrasion resistance and flexibility that withstands repeated bending and stretching without cracking. PVC coatings, while highly water-resistant, tend to be less flexible and more prone to cracking or peeling under prolonged mechanical stress and harsh environmental conditions. This makes polyurethane coatings a preferred choice for applications requiring long-lasting performance and rugged durability.

Water and Chemical Resistance Comparison

Polyurethane coating on polyester offers superior water resistance due to its non-porous, flexible barrier that prevents water penetration more effectively than PVC coatings. In terms of chemical resistance, polyurethane exhibits higher durability against oils, solvents, and acids, making it ideal for harsh environments where chemical exposure is frequent. PVC coatings provide good water resistance but can degrade faster under prolonged chemical contact, limiting their longevity compared to polyurethane-treated polyester fabrics.

Environmental Impact and Sustainability

Polyurethane coating on polyester offers superior environmental benefits compared to PVC coating, as it is free from chlorine and phthalates, reducing toxic chemical release during production and disposal. PVC coatings contribute significantly to environmental pollution due to their non-biodegradable nature and the release of harmful dioxins when incinerated. Sustainable polyester products increasingly favor polyurethane coatings for their lower ecological footprint and enhanced recyclability.

Flexibility and Handling: User Experience

Polyurethane (PU) coating on polyester offers superior flexibility, allowing fabrics to bend and stretch without cracking, which enhances user comfort and ease of handling. In contrast, PVC-coated polyester tends to be stiffer, limiting maneuverability and causing increased fatigue during prolonged use. PU coatings also provide a softer, more textile-like feel, improving tactile experience and making it the preferred choice for applications requiring frequent movement.

Cost Analysis: Polyurethane vs PVC

Polyurethane coating on polyester typically incurs higher initial costs compared to PVC coating due to more expensive raw materials and complex manufacturing processes. However, polyurethane offers superior durability and abrasion resistance, potentially reducing long-term maintenance and replacement expenses. PVC coating is generally more cost-effective upfront but may require more frequent repairs, impacting overall lifecycle costs.

Best Uses: Choosing the Right Coating for Your Needs

Polyurethane coating on polyester offers superior flexibility and breathability, making it ideal for outdoor apparel and sportswear that require comfort and durability. PVC coating provides excellent waterproofing and chemical resistance, best suited for heavy-duty applications like tarps, industrial covers, and inflatable products. Choosing between polyurethane and PVC coatings depends on the specific needs for flexibility, water resistance, and environmental exposure in your project.

Polyurethane Coating vs PVC Coating (on Polyester) Infographic

materialdif.com

materialdif.com