Polyester and PET (polyethylene terephthalate) are closely related materials, both belonging to the polyester family with PET being a specific type of polyester commonly used in fibers and packaging. Polyester typically refers to a broader category of polymers used in textiles, while PET is favored for its strength, durability, and recyclability, particularly in beverage bottles and fabric fibers. Understanding these differences helps industries select the right material based on performance requirements and sustainability goals.

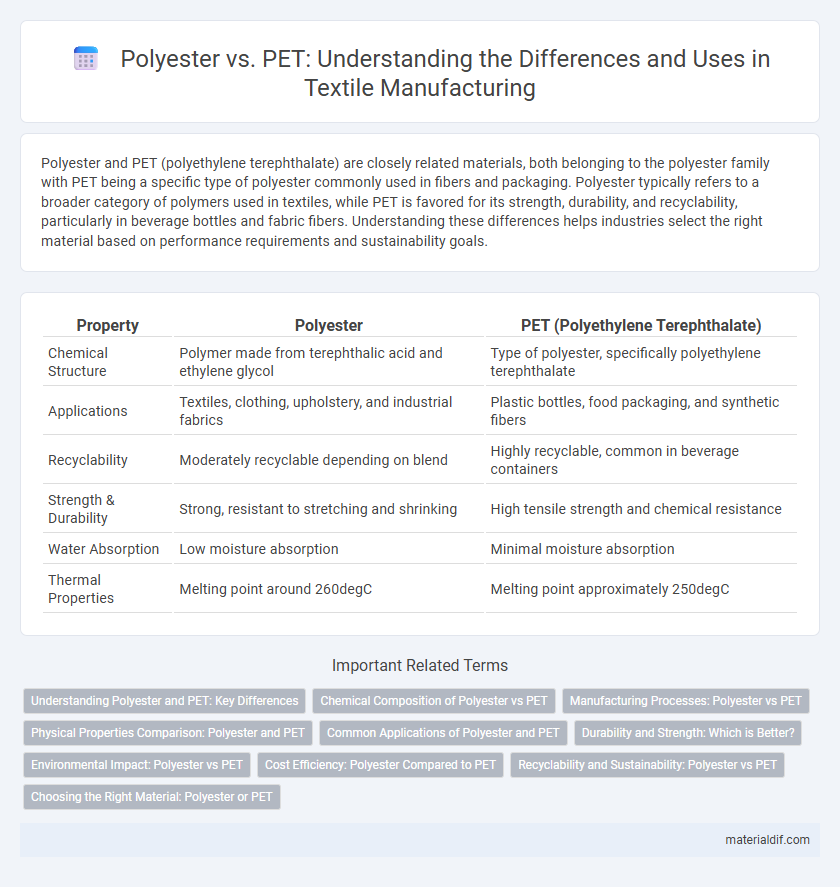

Table of Comparison

| Property | Polyester | PET (Polyethylene Terephthalate) |

|---|---|---|

| Chemical Structure | Polymer made from terephthalic acid and ethylene glycol | Type of polyester, specifically polyethylene terephthalate |

| Applications | Textiles, clothing, upholstery, and industrial fabrics | Plastic bottles, food packaging, and synthetic fibers |

| Recyclability | Moderately recyclable depending on blend | Highly recyclable, common in beverage containers |

| Strength & Durability | Strong, resistant to stretching and shrinking | High tensile strength and chemical resistance |

| Water Absorption | Low moisture absorption | Minimal moisture absorption |

| Thermal Properties | Melting point around 260degC | Melting point approximately 250degC |

Understanding Polyester and PET: Key Differences

Polyester and PET (Polyethylene Terephthalate) are related but distinct materials; polyester refers to a category of polymers used predominantly in textile fibers, while PET is a specific type of polyester commonly used in packaging and plastic bottles. PET's crystalline structure provides high strength, durability, and excellent chemical resistance, making it ideal for beverage containers and food packaging, whereas polyester fibers prioritize flexibility and breathability in fabric applications. Understanding these differences is crucial for selecting the appropriate material based on performance requirements and end-use, whether for textiles or packaging solutions.

Chemical Composition of Polyester vs PET

Polyester is a broad category of polymers primarily composed of ester functional groups in their main chain, with polyethylene terephthalate (PET) being the most common subtype made from the polycondensation of terephthalic acid and ethylene glycol. Chemically, PET features repeating units of ethylene terephthalate, giving it distinct thermoplastic properties and widespread use in fibers and packaging. The chemical composition of general polyesters may vary, including aliphatic or aromatic components, whereas PET consistently consists of aromatic rings from terephthalic acid, influencing its strength and durability.

Manufacturing Processes: Polyester vs PET

Polyester and PET (polyethylene terephthalate) share similar chemical compositions but differ notably in their manufacturing processes. Polyester is typically produced through a polycondensation reaction involving purified terephthalic acid (PTA) and ethylene glycol, resulting in fibers used extensively in textiles. In contrast, PET manufacturing primarily emphasizes pellet production through extrusion for applications in packaging, especially plastic bottles, highlighting distinct processing parameters despite their related polymer structure.

Physical Properties Comparison: Polyester and PET

Polyester and PET (polyethylene terephthalate) share similar molecular structures, but differ slightly in physical properties that impact their applications. PET typically exhibits higher tensile strength and greater chemical resistance, making it ideal for beverage containers and packaging. Polyester, with superior elasticity and moisture-wicking capabilities, is preferred in textile manufacturing and apparel due to its durability and comfort.

Common Applications of Polyester and PET

Polyester and PET (polyethylene terephthalate) are widely used in textiles and packaging, with polyester dominating apparel, home furnishings, and industrial fabrics due to its durability and moisture-wicking properties. PET is primarily utilized in the production of beverage bottles, food containers, and synthetic fibers, prized for its clarity, strength, and recyclability. Both materials find extensive use in the automotive sector and packaging industries, but polyester's versatility in textile manufacturing sets it apart from PET's major role in packaging and fiber production.

Durability and Strength: Which is Better?

Polyester and PET both offer high durability and strength, but PET typically surpasses polyester in tensile strength and resistance to impact, making it preferable for applications requiring robust performance. Polyester excels in flexibility and wrinkle resistance, which benefits textile and apparel industries seeking durability with comfort. For industrial uses demanding maximum durability and structural integrity, PET is often considered the superior choice.

Environmental Impact: Polyester vs PET

Polyester and PET (Polyethylene Terephthalate) share similar environmental impacts as both are derived from petroleum-based resources and are non-biodegradable, contributing to long-term pollution. PET is widely recycled into new packaging and textiles, reducing waste and energy consumption, whereas polyester from non-recycled sources tends to have a higher carbon footprint due to energy-intensive production. Sustainable alternatives like recycled polyester (rPET) significantly lower environmental damage by diverting plastic bottles from landfills and reducing reliance on virgin petrochemicals.

Cost Efficiency: Polyester Compared to PET

Polyester offers greater cost efficiency compared to PET due to its lower production expenses and versatile raw material sources, making it more economical for large-scale textile manufacturing. PET, primarily used in packaging and bottling, involves higher processing costs and stricter quality controls that increase overall expenses. Industries prioritize polyester in applications where budget constraints demand durable and affordable synthetic fibers without sacrificing performance.

Recyclability and Sustainability: Polyester vs PET

Polyester and PET both derive from polyethylene terephthalate, but PET is more commonly recycled due to established collection and processing infrastructure, enhancing its sustainability profile. Polyester can include variants with additives and blends that complicate recycling, reducing its overall recyclability compared to pure PET. The growing emphasis on circular economy practices favors PET recycling systems that decrease environmental impact and promote material reuse.

Choosing the Right Material: Polyester or PET

Polyester and PET (polyethylene terephthalate) share similar chemical structures but differ in applications and performance characteristics. Polyester is commonly used in textiles and fabrics for its durability and flexibility, while PET is preferred in packaging and bottles due to its high strength and clarity. Selecting the right material depends on the specific requirements such as mechanical strength, transparency, and thermal resistance.

Polyester vs PET Infographic

materialdif.com

materialdif.com