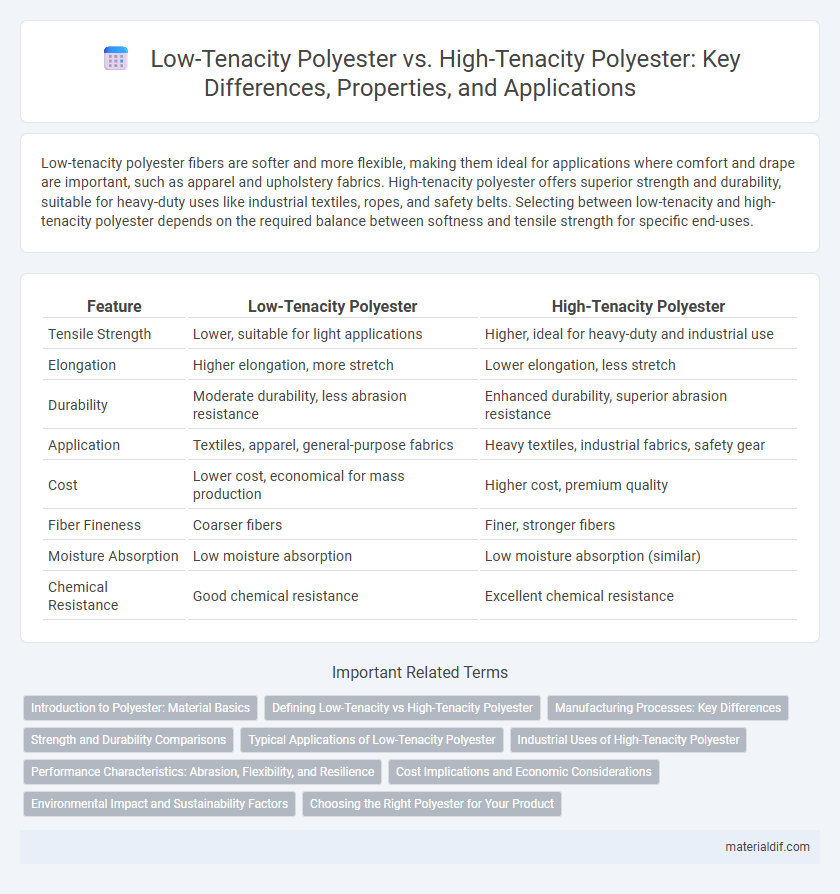

Low-tenacity polyester fibers are softer and more flexible, making them ideal for applications where comfort and drape are important, such as apparel and upholstery fabrics. High-tenacity polyester offers superior strength and durability, suitable for heavy-duty uses like industrial textiles, ropes, and safety belts. Selecting between low-tenacity and high-tenacity polyester depends on the required balance between softness and tensile strength for specific end-uses.

Table of Comparison

| Feature | Low-Tenacity Polyester | High-Tenacity Polyester |

|---|---|---|

| Tensile Strength | Lower, suitable for light applications | Higher, ideal for heavy-duty and industrial use |

| Elongation | Higher elongation, more stretch | Lower elongation, less stretch |

| Durability | Moderate durability, less abrasion resistance | Enhanced durability, superior abrasion resistance |

| Application | Textiles, apparel, general-purpose fabrics | Heavy textiles, industrial fabrics, safety gear |

| Cost | Lower cost, economical for mass production | Higher cost, premium quality |

| Fiber Fineness | Coarser fibers | Finer, stronger fibers |

| Moisture Absorption | Low moisture absorption | Low moisture absorption (similar) |

| Chemical Resistance | Good chemical resistance | Excellent chemical resistance |

Introduction to Polyester: Material Basics

Low-tenacity polyester typically exhibits tensile strengths ranging from 2.5 to 3.5 grams per denier, making it suitable for general applications such as textiles and apparel. High-tenacity polyester fibers, with tensile strengths exceeding 5 grams per denier, are engineered for demanding uses like industrial ropes, tire reinforcements, and high-performance composites. The fundamental difference between these variants lies in molecular orientation and crystallinity, influencing their mechanical properties and durability.

Defining Low-Tenacity vs High-Tenacity Polyester

Low-tenacity polyester fibers exhibit tensile strength typically below 4.5 grams per denier, making them suitable for lightweight applications like apparel and linings. High-tenacity polyester, with tensile strength exceeding 6.0 grams per denier, is engineered for demanding uses such as industrial textiles, ropes, and airbags, offering superior durability and resistance. The distinction between low and high-tenacity polyester lies in differences in molecular orientation and processing techniques, which directly impact fiber strength and performance characteristics.

Manufacturing Processes: Key Differences

Low-tenacity polyester is produced using standard melt spinning with moderate drawing ratios, resulting in fibers with lower molecular orientation and tensile strength. High-tenacity polyester employs enhanced drawing techniques and higher molecular weight polymers during melt spinning, yielding fibers with superior alignment and increased durability. These manufacturing distinctions directly influence mechanical properties, making high-tenacity polyester ideal for industrial applications requiring exceptional strength.

Strength and Durability Comparisons

Low-tenacity polyester fibers typically exhibit tensile strengths ranging from 3.5 to 4.5 grams per denier, making them suitable for applications where flexibility and softness are prioritized over maximum strength. High-tenacity polyester fibers, with tensile strengths exceeding 7.0 grams per denier, offer significantly enhanced durability and resistance to abrasion, ideal for heavy-duty industrial uses such as tire cords, conveyor belts, and high-performance textiles. The increased molecular orientation and crystallinity in high-tenacity polyester contribute to its superior mechanical properties, delivering prolonged service life under intense stress conditions compared to low-tenacity variants.

Typical Applications of Low-Tenacity Polyester

Low-tenacity polyester is commonly used in applications requiring flexibility and softness, such as textile fabrics, upholstery, and apparel linings. Its lower strength compared to high-tenacity polyester makes it ideal for items like curtains, non-woven fabrics, and disposable medical products. These typical uses capitalize on its lightweight and easy-to-dye properties without the need for high tensile strength.

Industrial Uses of High-Tenacity Polyester

High-tenacity polyester exhibits superior strength and durability compared to low-tenacity polyester, making it ideal for demanding industrial applications. It is widely used in manufacturing conveyor belts, tire reinforcements, safety harnesses, and heavy-duty fishing nets due to its excellent tensile strength and resistance to abrasion. These properties ensure longevity and reliability in harsh environments, driving its preference in industrial sectors.

Performance Characteristics: Abrasion, Flexibility, and Resilience

Low-tenacity polyester offers greater flexibility and moderate abrasion resistance, making it suitable for applications requiring lightweight and supple materials. High-tenacity polyester exhibits superior abrasion resistance and enhanced resilience, ideal for heavy-duty uses demanding durability and long-term performance. The choice between the two depends on the specific balance needed between flexibility and toughness in the end application.

Cost Implications and Economic Considerations

Low-tenacity polyester fibers typically cost less due to lower production energy and simpler processing, making them ideal for budget-conscious applications. High-tenacity polyester demands higher raw material quality and advanced manufacturing techniques, driving up costs but delivering superior strength and durability for industrial use. Choosing between these types depends on balancing upfront expenses against long-term performance and maintenance savings.

Environmental Impact and Sustainability Factors

Low-tenacity polyester, typically used in lightweight textiles, requires less energy during production but tends to have a shorter lifespan, increasing waste generation and environmental burden. High-tenacity polyester, favored for industrial applications, offers greater durability and resistance, reducing replacement frequency and contributing to longer product life cycles, which can lower overall environmental impact. Both types face challenges with microplastic pollution and recyclability, making advancements in sustainable recycling technologies critical for minimizing their ecological footprint.

Choosing the Right Polyester for Your Product

Low-tenacity polyester offers flexibility and lightweight properties, making it ideal for textiles requiring softness and comfort such as apparel and home furnishings. High-tenacity polyester provides superior strength and durability, preferred for industrial applications like seat belts, conveyor belts, and outdoor gear. Selecting the right polyester depends on balancing tensile strength requirements with the desired texture and flexibility specific to the end-use product.

Low-tenacity Polyester vs High-tenacity Polyester Infographic

materialdif.com

materialdif.com