Polyester microfiber offers superior softness and enhanced breathability compared to regular polyester fiber, making it ideal for clothing and upholstery that require comfort and durability. The finer strands in microfiber create a denser fabric that resists stains and dries faster, providing practical benefits over standard polyester fibers. While regular polyester fibers are robust and cost-effective, microfiber's advanced weave delivers better moisture-wicking properties and a lightweight feel.

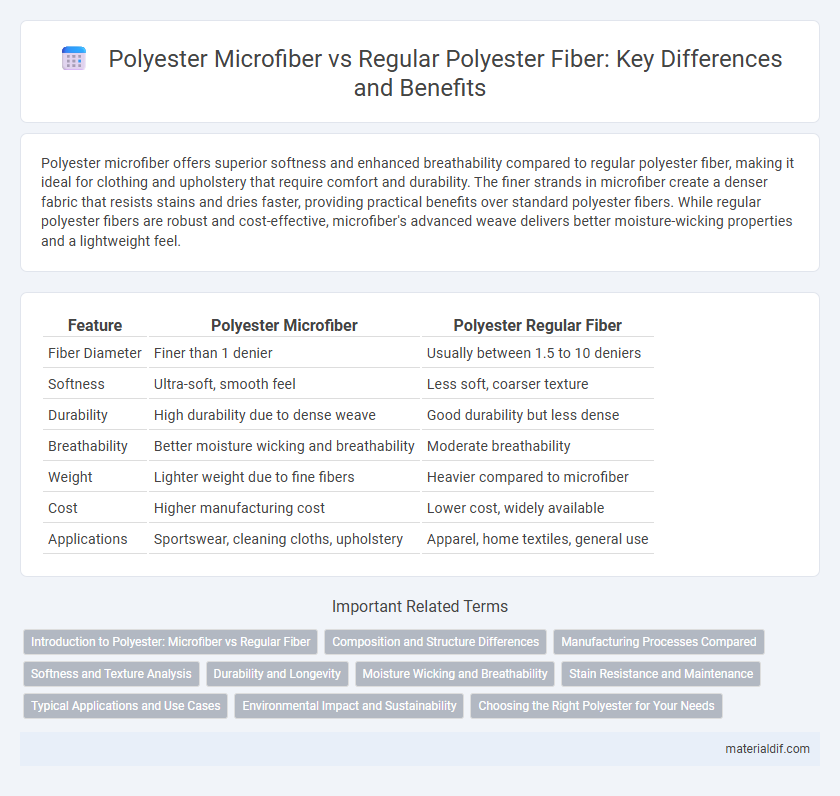

Table of Comparison

| Feature | Polyester Microfiber | Polyester Regular Fiber |

|---|---|---|

| Fiber Diameter | Finer than 1 denier | Usually between 1.5 to 10 deniers |

| Softness | Ultra-soft, smooth feel | Less soft, coarser texture |

| Durability | High durability due to dense weave | Good durability but less dense |

| Breathability | Better moisture wicking and breathability | Moderate breathability |

| Weight | Lighter weight due to fine fibers | Heavier compared to microfiber |

| Cost | Higher manufacturing cost | Lower cost, widely available |

| Applications | Sportswear, cleaning cloths, upholstery | Apparel, home textiles, general use |

Introduction to Polyester: Microfiber vs Regular Fiber

Polyester microfiber consists of ultra-fine fibers measuring less than one denier, offering a softer texture and enhanced breathability compared to regular polyester fibers, which are thicker and less flexible. The reduced diameter of polyester microfiber increases surface area, resulting in superior moisture-wicking properties and a smoother finish ideal for activewear and luxury textiles. Regular polyester fiber, while more durable and resistant to wrinkles, lacks the refined softness and lightweight comfort typical of microfiber, making each type suitable for different textile applications.

Composition and Structure Differences

Polyester microfiber consists of ultra-fine fibers typically less than 1 denier, created through advanced spinning techniques that produce a softer, more flexible structure compared to regular polyester fibers, which are thicker and coarser. The composition of both is fundamentally polyethylene terephthalate (PET), but microfiber's finer denier results in a higher surface area, enhancing moisture-wicking and breathability properties. Structurally, polyester microfiber weaves more densely, offering increased durability and a smoother texture ideal for applications in performance textiles and high-end upholstery.

Manufacturing Processes Compared

Polyester microfiber is produced through a specialized manufacturing process that extrudes ultra-fine strands, significantly thinner than regular polyester fibers, enhancing softness and moisture-wicking properties. Regular polyester fiber manufacturing involves standard melt spinning techniques yielding thicker fibers with more rigidity and lower surface area. The micro-denier scale of microfiber requires precise temperature and cooling control during extrusion, resulting in enhanced performance characteristics compared to conventional polyester fiber production.

Softness and Texture Analysis

Polyester microfiber features significantly finer threads than regular polyester fiber, resulting in a softer, smoother texture that mimics natural fabrics like silk or cotton. The dense weave of microfiber enhances softness by minimizing coarse fiber ends, providing a lightweight, breathable, and luxurious feel. In contrast, regular polyester fibers tend to be coarser and less flexible, which can lead to a stiffer texture and reduced comfort in textile applications.

Durability and Longevity

Polyester microfiber exhibits greater durability and longevity compared to regular polyester fiber due to its finer strands, which create a tighter weave and enhance resistance to wear and tear. The enhanced fiber density of microfiber reduces pilling and maintains fabric integrity after repeated washing and extended use. This superior durability makes polyester microfiber ideal for high-traffic applications such as upholstery and activewear.

Moisture Wicking and Breathability

Polyester microfiber offers enhanced moisture-wicking properties compared to regular polyester fiber due to its finer strands that increase surface area and promote faster evaporation of sweat. The tighter weave of regular polyester fibers often limits breathability, while microfiber's lightweight and porous structure allows for better air circulation, improving comfort during physical activities. High-performance athletic wear frequently utilizes polyester microfiber for its superior moisture management and ventilation capabilities.

Stain Resistance and Maintenance

Polyester microfiber offers superior stain resistance compared to regular polyester fiber due to its finer threads, which create a denser fabric that repels liquids more effectively. Maintenance is easier with microfiber as it resists dirt and stains, requiring less frequent washing and gentler cleaning methods. Regular polyester fiber, while durable, tends to absorb stains more readily and may need stronger detergents and more frequent laundering to maintain its appearance.

Typical Applications and Use Cases

Polyester microfiber, characterized by its ultrafine fibers measuring less than one denier, is widely used in high-performance activewear, cleaning cloths, and luxury bedding due to its softness, breathability, and enhanced moisture-wicking properties. Regular polyester fiber, with thicker fibers typically above one denier, finds common applications in durable outerwear, upholstery fabrics, and industrial textiles where strength and abrasion resistance are prioritized. The microfiber variant excels in products requiring a finer texture and higher flexibility, while regular polyester is preferred for cost-effective, robust materials in everyday use.

Environmental Impact and Sustainability

Polyester microfiber, due to its finer strands, often sheds more microplastics into waterways, posing greater environmental risks compared to regular polyester fiber. Regular polyester fiber, while still derived from petrochemicals, generally has a lower microfiber release during washing, reducing its contribution to microplastic pollution. Sustainable alternatives include recycled polyester fibers that significantly lower carbon footprints and resource consumption compared to virgin polyester production.

Choosing the Right Polyester for Your Needs

Polyester microfiber features ultra-fine strands that create a soft, lightweight fabric ideal for activewear and delicate textiles, while regular polyester fiber offers durability and strength suited for upholstery and outerwear applications. Microfiber's moisture-wicking and quick-drying properties enhance comfort during physical activities, whereas regular polyester provides higher resistance to abrasion and holds shape well in heavy-use environments. Selecting the right polyester depends on application demands, balancing softness and breathability with durability and structural integrity.

Polyester Microfiber vs Polyester Regular Fiber Infographic

materialdif.com

materialdif.com