Texturized polyester offers enhanced breathability and elasticity compared to non-texturized polyester, making it ideal for activewear and comfort-focused textiles. The texturizing process creates a bulkier, softer fabric with improved moisture-wicking properties, while non-texturized polyester tends to be smoother, more durable, and less absorbent. Choosing between them depends on the desired fabric performance, with texturized polyester favored for flexibility and comfort, and non-texturized polyester preferred for strength and resistance to wrinkles.

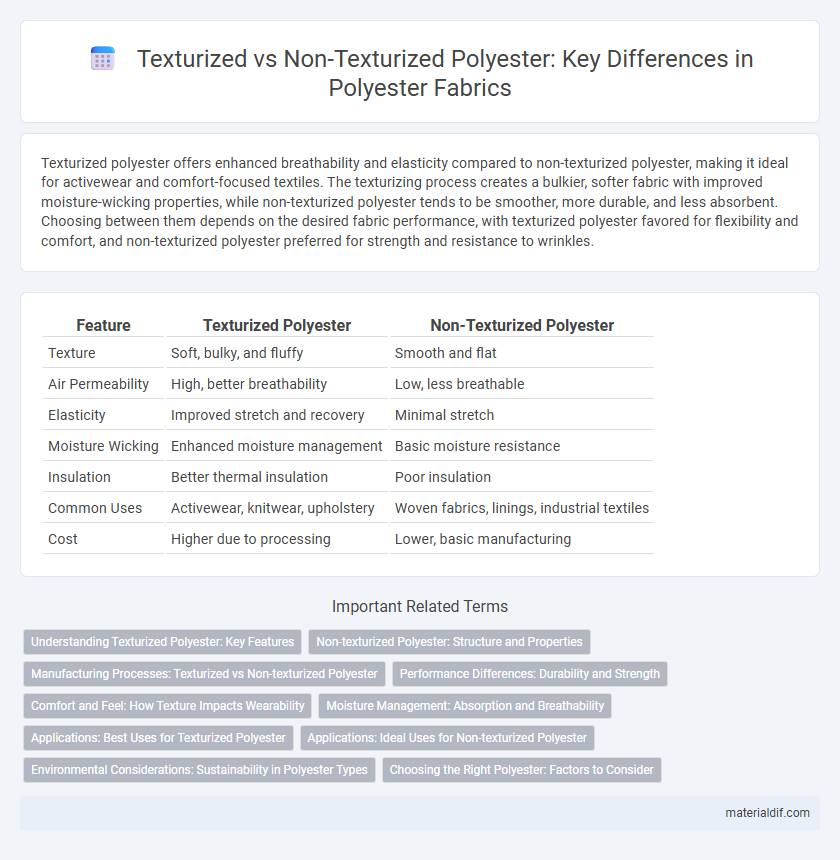

Table of Comparison

| Feature | Texturized Polyester | Non-Texturized Polyester |

|---|---|---|

| Texture | Soft, bulky, and fluffy | Smooth and flat |

| Air Permeability | High, better breathability | Low, less breathable |

| Elasticity | Improved stretch and recovery | Minimal stretch |

| Moisture Wicking | Enhanced moisture management | Basic moisture resistance |

| Insulation | Better thermal insulation | Poor insulation |

| Common Uses | Activewear, knitwear, upholstery | Woven fabrics, linings, industrial textiles |

| Cost | Higher due to processing | Lower, basic manufacturing |

Understanding Texturized Polyester: Key Features

Texturized polyester features fibers that have been processed to add volume, bulk, and elasticity, resulting in a softer feel and enhanced moisture-wicking properties. This modification improves breathability and thermal insulation, making texturized polyester ideal for activewear and performance fabrics. In contrast, non-texturized polyester maintains a smooth, flat surface with lower stretch and less air permeability, often used in durable, lightweight applications.

Non-texturized Polyester: Structure and Properties

Non-texturized polyester features a smooth and compact filament structure, resulting in a fabric that is lightweight and has a sleek surface with minimal air entrapment. This structure enhances tensile strength and resistance to abrasion, making it ideal for applications requiring durability and a polished appearance. The low moisture absorption and quick-drying properties contribute to its widespread use in activewear and industrial textiles.

Manufacturing Processes: Texturized vs Non-texturized Polyester

Texturized polyester is produced through a specialized process involving mechanical or thermal treatment that alters the fiber's structure to create bulk, softness, and elasticity, enhancing fabric stretch and moisture absorption. Non-texturized polyester undergoes a simpler manufacturing process where fibers remain smooth and flat, resulting in a firmer texture with less breathability and flexibility. These distinct production methods directly influence the performance characteristics and applications of each polyester type in textiles and apparel.

Performance Differences: Durability and Strength

Texturized polyester exhibits enhanced durability and strength due to its increased fiber bulk and elasticity, which improves resistance to abrasion and stretching. Non-texturized polyester, while smooth and strong, lacks the resilience provided by the texturizing process, making it less effective for applications requiring high tensile strength and flexibility. The performance differences emphasize that texturized polyester offers superior mechanical properties for demanding use in textiles and industrial fabrics.

Comfort and Feel: How Texture Impacts Wearability

Texturized polyester features a crimped or twisted fiber structure that enhances breathability and softness, resulting in increased comfort and a more natural feel against the skin. Non-texturized polyester, with its smooth, flat fibers, tends to be less breathable and may feel stiffer or less flexible, impacting overall wearability. The textured surface of texturized polyester allows better moisture-wicking and air circulation, making it preferable for activewear and garments requiring high comfort levels.

Moisture Management: Absorption and Breathability

Texturized polyester offers superior moisture management through enhanced absorption and breathability due to its increased surface area and air pockets, which facilitate better sweat-wicking and ventilation. Non-texturized polyester tends to trap moisture against the skin, leading to reduced comfort and slower drying times. The unique structure of texturized fibers promotes a cooler, drier experience, making it ideal for activewear and performance textiles.

Applications: Best Uses for Texturized Polyester

Texturized polyester is ideal for applications requiring enhanced elasticity, breathability, and softness, making it suitable for activewear, sportswear, and intimate apparel. Its crimped fibers improve moisture management and thermal insulation, perfect for outdoor clothing and upholstery. Non-texturized polyester, conversely, is more rigid and often used in industrial textiles, linings, and durable everyday apparel.

Applications: Ideal Uses for Non-texturized Polyester

Non-texturized polyester is widely used in applications requiring smooth, flat fabrics such as linings, interlinings, and industrial textiles due to its strength and durability. Its non-bulky nature makes it ideal for high-performance sportswear, upholstery, and wovens where a sleek appearance and lightweight fabric are essential. This type of polyester excels in environments demanding moisture resistance, wrinkle retention, and quick drying.

Environmental Considerations: Sustainability in Polyester Types

Texturized polyester, created through a mechanical process that adds bulk and stretch, often requires more energy and water, resulting in a higher environmental impact compared to non-texturized polyester, which is produced with less intensive processing. Both types rely on petrochemical sources, but advancements in recycling and bio-based alternatives are critical to improving the sustainability profile of polyester fabrics. Choosing recycled polyester can significantly reduce carbon footprint and water usage regardless of texture, positioning it as a more eco-friendly option in the textile industry.

Choosing the Right Polyester: Factors to Consider

Texturized polyester offers enhanced breathability, stretch, and a softer feel, making it ideal for activewear and comfortable apparel, while non-texturized polyester provides a smoother surface and is better suited for formal wear and structured garments. Key factors to consider when choosing the right polyester include the intended garment use, desired fabric texture, moisture-wicking properties, and durability requirements. Evaluating these elements ensures optimal performance and comfort tailored to specific clothing applications.

Texturized Polyester vs Non-texturized Polyester Infographic

materialdif.com

materialdif.com