High tenacity polyester offers significantly greater strength and durability compared to regular polyester, making it ideal for heavy-duty applications. Its enhanced tensile strength allows it to withstand higher stress and wear, which extends the lifespan of products such as industrial fabrics, ropes, and outdoor gear. Regular polyester, while versatile and cost-effective, lacks the robustness needed for demanding environments.

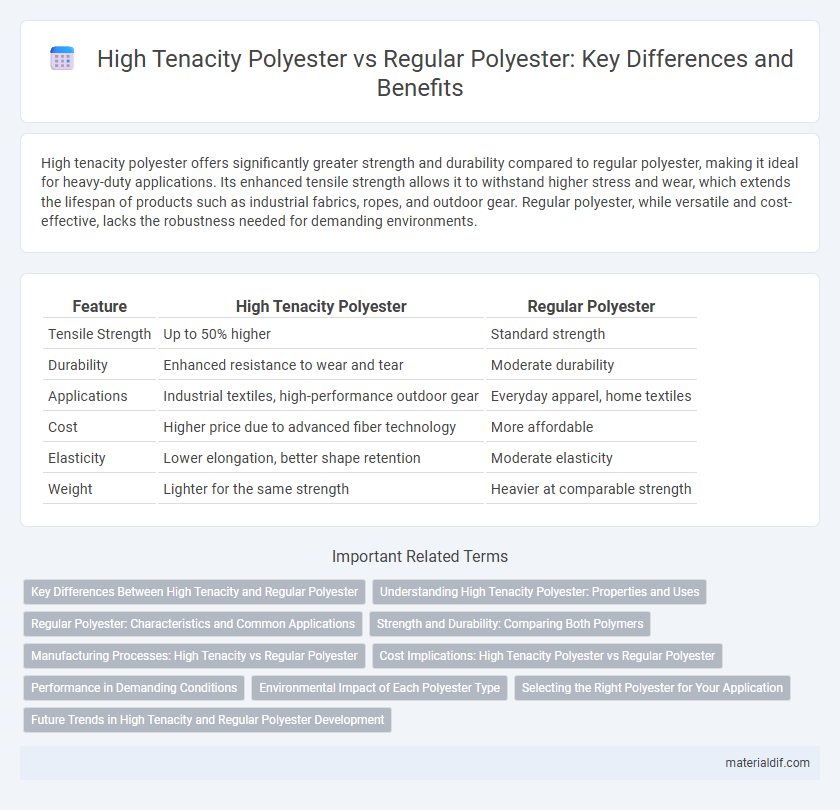

Table of Comparison

| Feature | High Tenacity Polyester | Regular Polyester |

|---|---|---|

| Tensile Strength | Up to 50% higher | Standard strength |

| Durability | Enhanced resistance to wear and tear | Moderate durability |

| Applications | Industrial textiles, high-performance outdoor gear | Everyday apparel, home textiles |

| Cost | Higher price due to advanced fiber technology | More affordable |

| Elasticity | Lower elongation, better shape retention | Moderate elasticity |

| Weight | Lighter for the same strength | Heavier at comparable strength |

Key Differences Between High Tenacity and Regular Polyester

High tenacity polyester fibers exhibit significantly higher tensile strength and durability compared to regular polyester, making them ideal for demanding industrial applications like ropes, conveyor belts, and safety harnesses. The molecular structure of high tenacity polyester is more oriented and crystalline, resulting in enhanced abrasion resistance and dimensional stability under stress. Regular polyester, while versatile and cost-effective, typically offers lower strength and elasticity, limiting its use to everyday textiles and apparel.

Understanding High Tenacity Polyester: Properties and Uses

High Tenacity Polyester offers superior tensile strength and durability compared to regular polyester, making it ideal for demanding applications such as industrial fabrics, safety belts, and outdoor gear. Its enhanced resistance to abrasion, UV exposure, and chemicals significantly extends the lifespan of products in harsh environments. This specialized polyester variant is favored in sectors requiring robust performance without compromising lightweight flexibility.

Regular Polyester: Characteristics and Common Applications

Regular polyester is a versatile synthetic fiber known for its moderate strength, durability, and resistance to stretching and shrinking. It is widely used in apparel, home textiles such as curtains and upholstery, and industrial fabrics due to its affordability and ease of care. Common applications also include lightweight outdoor gear, fashion accessories, and everyday clothing where flexibility and comfort are prioritized over extreme tensile strength.

Strength and Durability: Comparing Both Polymers

High tenacity polyester fibers exhibit significantly greater tensile strength than regular polyester, making them ideal for applications demanding enhanced durability and resistance to wear. The molecular alignment in high tenacity polyester results in superior load-bearing capacity and improved elongation properties, which contribute to its robustness under stress. Consequently, high tenacity polyester outperforms regular polyester in environments subject to mechanical strain, extending the lifespan of products such as industrial fabrics and high-performance textiles.

Manufacturing Processes: High Tenacity vs Regular Polyester

High tenacity polyester is manufactured through a specialized process involving higher drawing ratios and controlled molecular orientation, resulting in fibers with superior strength and durability compared to regular polyester. Regular polyester is produced using standard spinning and drawing techniques that provide adequate tensile strength for everyday applications but lack the enhanced performance characteristics of high tenacity fibers. The manufacturing differentiation primarily lies in the tension and thermal treatment during fiber extrusion, which significantly boosts the mechanical properties of high tenacity polyester.

Cost Implications: High Tenacity Polyester vs Regular Polyester

High tenacity polyester typically incurs higher initial costs due to its enhanced fiber strength and durability, which demand advanced manufacturing processes. In contrast, regular polyester is more cost-effective upfront but may lead to increased long-term expenses because of its lower tensile strength and shorter lifespan. Businesses must evaluate these cost implications by balancing upfront investment against potential savings from reduced maintenance and replacement frequencies.

Performance in Demanding Conditions

High tenacity polyester fibers offer superior tensile strength and durability compared to regular polyester, making them ideal for demanding applications such as industrial textiles and outdoor gear. Their enhanced resistance to abrasion, UV exposure, and chemical agents ensures long-lasting performance under harsh environmental conditions. This makes high tenacity polyester the preferred choice for products requiring exceptional mechanical properties and reliability.

Environmental Impact of Each Polyester Type

High tenacity polyester, engineered for superior strength and durability, generally requires more energy and resources during production compared to regular polyester, resulting in a higher environmental footprint. However, its enhanced durability extends the product lifespan, reducing frequency of replacement and long-term waste generation. Regular polyester, while less resource-intensive to manufacture, often leads to faster wear and disposal, contributing to increased microplastic pollution and landfill accumulation over time.

Selecting the Right Polyester for Your Application

High tenacity polyester offers superior tensile strength and durability compared to regular polyester, making it ideal for applications requiring enhanced resistance to abrasion and heavy loads. Regular polyester provides cost-effective versatility suitable for everyday use, including textiles and lightweight industrial purposes. Selecting the right polyester depends on evaluating performance needs, such as load-bearing capacity, environmental exposure, and longevity requirements within your specific application.

Future Trends in High Tenacity and Regular Polyester Development

High tenacity polyester fibers offer enhanced strength and durability compared to regular polyester, making them ideal for industrial applications and high-performance textiles. Future trends indicate a shift towards sustainable production methods and bio-based polymers to reduce environmental impact while maintaining or improving fiber strength. Advances in nanotechnology and smart fabric integration are expected to drive innovation in both high tenacity and regular polyester markets, expanding their functionality and application range.

High Tenacity Polyester vs Regular Polyester Infographic

materialdif.com

materialdif.com