Polyester Tricot offers a smooth, soft texture with excellent durability, making it ideal for linings and activewear, while Polyester Mesh features a breathable, open-weave structure that promotes airflow and moisture wicking, perfect for sports jerseys and outdoor apparel. Tricot's fine knit construction provides better stretch and a sleek appearance, whereas Mesh prioritizes ventilation and lightweight comfort. Choosing between these fabrics depends on the desired balance of breathability and texture for specific garment performance.

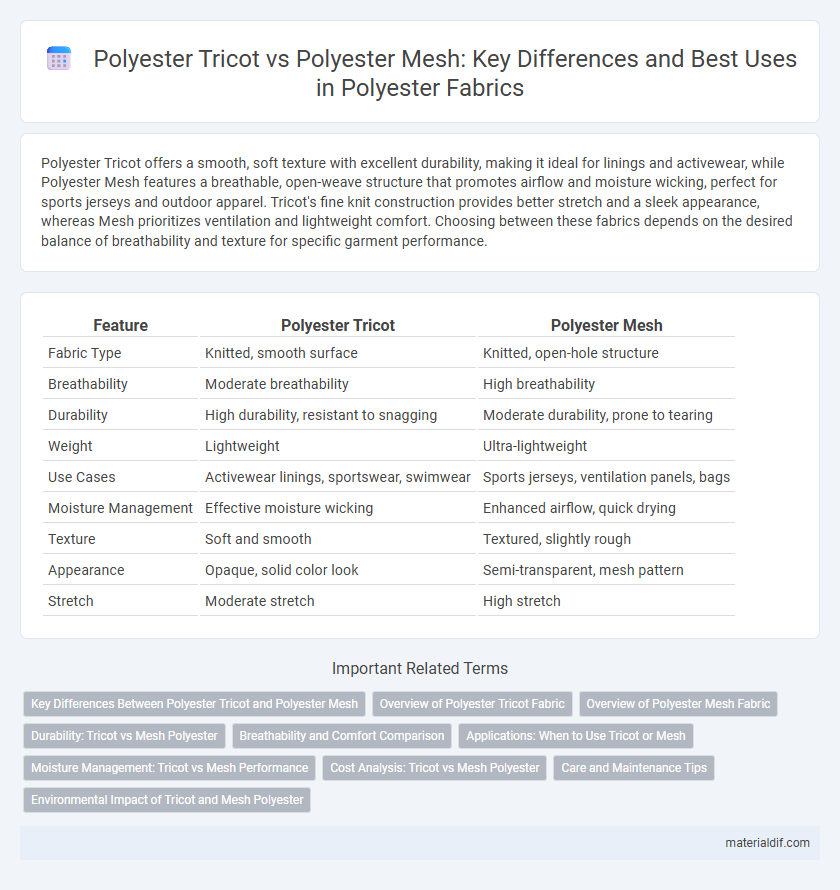

Table of Comparison

| Feature | Polyester Tricot | Polyester Mesh |

|---|---|---|

| Fabric Type | Knitted, smooth surface | Knitted, open-hole structure |

| Breathability | Moderate breathability | High breathability |

| Durability | High durability, resistant to snagging | Moderate durability, prone to tearing |

| Weight | Lightweight | Ultra-lightweight |

| Use Cases | Activewear linings, sportswear, swimwear | Sports jerseys, ventilation panels, bags |

| Moisture Management | Effective moisture wicking | Enhanced airflow, quick drying |

| Texture | Soft and smooth | Textured, slightly rough |

| Appearance | Opaque, solid color look | Semi-transparent, mesh pattern |

| Stretch | Moderate stretch | High stretch |

Key Differences Between Polyester Tricot and Polyester Mesh

Polyester Tricot features a smooth, tightly woven knit that offers excellent stretch and durability, making it ideal for activewear and linings. In contrast, Polyester Mesh consists of an open, porous knit structure that provides superior breathability and moisture-wicking properties, commonly used in sports jerseys and performance garments. The key differences lie in their texture, breathability, and typical applications, with Tricot prioritizing comfort and resilience while Mesh emphasizes ventilation and lightweight wear.

Overview of Polyester Tricot Fabric

Polyester Tricot fabric is a smooth, warp-knit textile known for its durability, lightweight texture, and excellent stretch properties, making it ideal for activewear and performance garments. Its fine, tightly knit construction provides a soft hand feel and enhances moisture-wicking capabilities compared to polyester mesh, which features an open, breathable structure. The dense weave of polyester tricot contributes to better insulation and wind resistance, distinguishing it from the airier, more ventilated polyester mesh fabrics.

Overview of Polyester Mesh Fabric

Polyester mesh fabric features an open, breathable structure created by interlocking polyester yarns in a grid-like pattern, making it ideal for ventilation and moisture-wicking applications. It is commonly used in activewear, sports jerseys, and outdoor gear due to its durability, lightweight feel, and quick-drying properties. Compared to polyester tricot, polyester mesh offers superior airflow and enhanced comfort in high-performance or warm-weather environments.

Durability: Tricot vs Mesh Polyester

Polyester Tricot features a tight, smooth knit that enhances durability by resisting snagging and stretching, making it ideal for activewear and swimwear. In contrast, Polyester Mesh offers superior breathability but has a more open structure, which can reduce its durability against abrasion and tearing. Choosing between Tricot and Mesh polyester depends on the balance needed between durability and ventilation in the garment.

Breathability and Comfort Comparison

Polyester Tricot features a smooth, tightly knit surface that offers moderate breathability, making it ideal for lightweight, comfortable apparel with a soft hand feel. Polyester Mesh, characterized by its open, porous construction, excels in breathability and moisture-wicking capabilities, enhancing ventilation and keeping the wearer cool during intense physical activity. For activewear and sports uniforms, Polyester Mesh provides superior comfort and airflow compared to the denser, less ventilated Polyester Tricot.

Applications: When to Use Tricot or Mesh

Polyester Tricot, with its smooth surface and lightweight durability, is ideal for activewear, swimwear, and linings where comfort and a soft touch are essential. Polyester Mesh is best suited for athletic apparel and gear requiring enhanced breathability and ventilation, such as jerseys, sports uniforms, and outdoor equipment. Choosing Tricot ensures moisture-wicking and stretchability, while Mesh maximizes airflow and temperature regulation in high-intensity activities.

Moisture Management: Tricot vs Mesh Performance

Polyester tricot features a tight-knit construction that offers moderate moisture-wicking capabilities, making it suitable for lightweight, breathable athletic wear. Polyester mesh, with its open-hole design, excels in moisture management by allowing superior airflow and faster evaporation of sweat, ideal for high-intensity activities. Mesh fabric's enhanced ventilation reduces heat buildup, providing better comfort during prolonged physical exertion compared to the denser tricot weave.

Cost Analysis: Tricot vs Mesh Polyester

Polyester tricot is generally more expensive than polyester mesh due to its tighter knit construction, which requires more material and labor-intensive weaving processes. Polyester mesh, with its open-knit design, offers cost advantages in production and breathability, making it a budget-friendly option for applications prioritizing ventilation over surface smoothness. Evaluating polyester tricot vs mesh in cost analysis highlights the balance between durability, texture quality, and manufacturing expenses.

Care and Maintenance Tips

Polyester tricot requires gentle washing in cold water to preserve its smooth texture and avoid shrinkage, with air drying recommended to maintain fabric integrity. Polyester mesh benefits from hand washing or machine washing on a delicate cycle to prevent snagging, and it is best dried flat to retain its breathable structure. Avoid bleach and harsh detergents on both fabrics to extend their lifespan and maintain color vibrancy.

Environmental Impact of Tricot and Mesh Polyester

Polyester tricot and polyester mesh differ significantly in environmental impact due to their manufacturing processes and material structure. Tricot polyester, typically produced with a tighter knit, often requires more energy and water during dyeing and finishing, leading to higher carbon emissions compared to the more open-weave polyester mesh, which generally uses less energy and resources. However, polyester mesh's increased surface area can lead to greater microplastic shedding during washing, posing a higher risk to aquatic ecosystems than tricot polyester.

Polyester Tricot vs Polyester Mesh Infographic

materialdif.com

materialdif.com