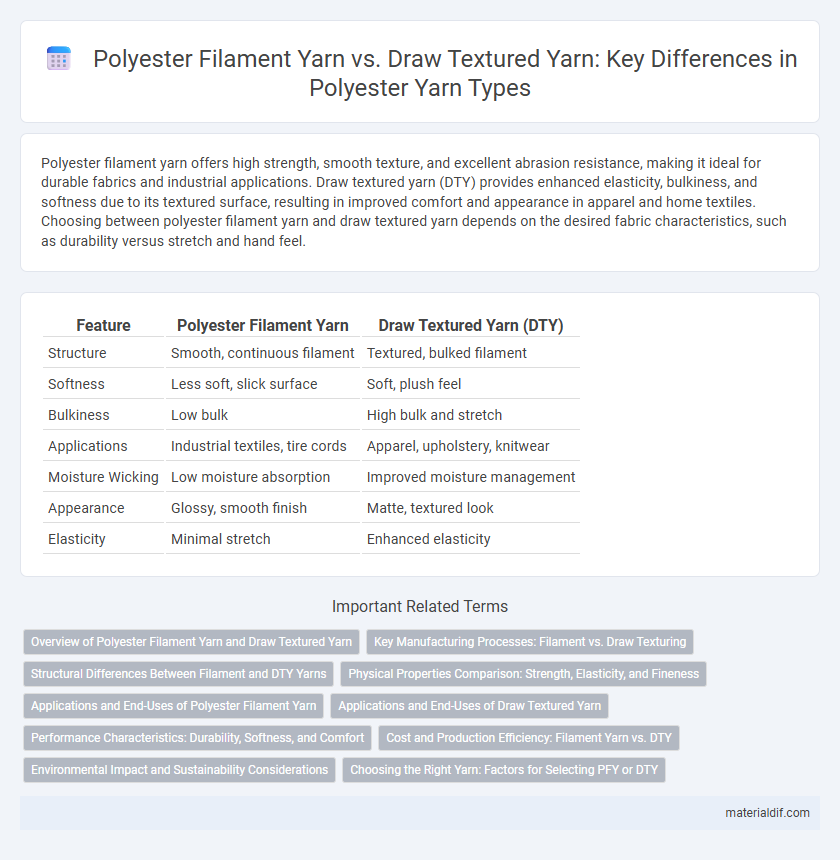

Polyester filament yarn offers high strength, smooth texture, and excellent abrasion resistance, making it ideal for durable fabrics and industrial applications. Draw textured yarn (DTY) provides enhanced elasticity, bulkiness, and softness due to its textured surface, resulting in improved comfort and appearance in apparel and home textiles. Choosing between polyester filament yarn and draw textured yarn depends on the desired fabric characteristics, such as durability versus stretch and hand feel.

Table of Comparison

| Feature | Polyester Filament Yarn | Draw Textured Yarn (DTY) |

|---|---|---|

| Structure | Smooth, continuous filament | Textured, bulked filament |

| Softness | Less soft, slick surface | Soft, plush feel |

| Bulkiness | Low bulk | High bulk and stretch |

| Applications | Industrial textiles, tire cords | Apparel, upholstery, knitwear |

| Moisture Wicking | Low moisture absorption | Improved moisture management |

| Appearance | Glossy, smooth finish | Matte, textured look |

| Elasticity | Minimal stretch | Enhanced elasticity |

Overview of Polyester Filament Yarn and Draw Textured Yarn

Polyester filament yarn consists of continuous filaments providing high strength, smooth texture, and excellent dimensional stability, making it ideal for industrial applications and high-quality textiles. Draw textured yarn (DTY) is produced by drawing, texturizing, and twisting filament yarns, resulting in enhanced elasticity, bulkiness, and softness suitable for apparel and home furnishings. Both yarn types leverage polyester's durability and moisture-wicking properties but differ in texture and end-use performance.

Key Manufacturing Processes: Filament vs. Draw Texturing

Polyester filament yarn is produced through a continuous extrusion process that creates smooth, unbroken synthetic fibers, resulting in high tensile strength and uniformity ideal for weaving and knitting. Draw textured yarn undergoes an additional draw texturing process involving simultaneous drawing and false-twist texturizing, which imparts bulk, elasticity, and a softer hand feel, making it suitable for stretch fabrics and improved fabric aesthetics. The key manufacturing difference lies in the filament yarn's direct extrusion versus the draw textured yarn's mechanical modification to enhance texture and stretchability.

Structural Differences Between Filament and DTY Yarns

Polyester filament yarn consists of continuous, smooth filaments that provide uniform strength and low elasticity, making it ideal for applications requiring durability and sheen. Draw textured yarn (DTY) is produced by drawing and texturizing polyester filaments, imparting bulkiness, stretch, and enhanced softness due to its fully drawn and textured structure. The structural difference lies in the filament's smooth, straight construction versus DTY's crimped and bulked fibers, influencing fabric properties like elasticity, appearance, and comfort.

Physical Properties Comparison: Strength, Elasticity, and Fineness

Polyester filament yarn exhibits higher tensile strength and superior durability compared to draw textured yarn, making it suitable for heavy-duty textile applications. Draw textured yarn offers enhanced elasticity due to the texturing process, providing better stretch and recovery, which is ideal for garments requiring comfort and flexibility. Fineness in polyester filament yarn is typically uniform and smooth, while draw textured yarn has increased bulk and softness, influencing fabric hand feel and appearance.

Applications and End-Uses of Polyester Filament Yarn

Polyester filament yarn finds extensive applications in high-strength textiles such as industrial filters, tire cords, and conveyor belts due to its durability and smooth texture, while draw textured yarn is predominantly used in apparel and home textiles for its bulkier, stretchable properties. The filament yarn's low elongation and high tensile strength make it ideal for technical textiles requiring dimensional stability. End-uses of polyester filament yarn also include upholstery, automotive interiors, and ropes where uniformity and resistance to abrasion are critical.

Applications and End-Uses of Draw Textured Yarn

Draw textured yarn (DTY) is widely used in apparel manufacturing, particularly in activewear, casual wear, and lingerie due to its soft hand feel, stretchability, and enhanced breathability compared to polyester filament yarn (PFY). DTY's textured surface improves dye uptake, making it ideal for vibrant fashion garments and home textiles like curtains and upholstery. Its elasticity and durability also support uses in industrial textiles such as automotive seat belts and safety belts, where strength and resilience are critical.

Performance Characteristics: Durability, Softness, and Comfort

Polyester filament yarn exhibits superior durability due to its continuous filaments, providing high tensile strength and resistance to abrasion, making it ideal for long-lasting textile applications. Draw textured yarn, created through the drawing and texturing process, enhances softness and comfort by introducing bulk and elasticity, closely mimicking natural fibers in hand feel and breathability. The choice between polyester filament yarn and draw textured yarn depends on prioritizing either durability or comfort for end-use performance in apparel and upholstery.

Cost and Production Efficiency: Filament Yarn vs. DTY

Polyester filament yarn typically offers lower production costs due to its direct manufacturing process and higher production speeds, making it more cost-effective for bulk applications. In contrast, draw textured yarn (DTY) involves additional texturizing steps that increase production time and energy consumption, leading to higher costs but enhanced yarn elasticity and bulk. Filament yarns excel in efficiency and cost savings, while DTY provides superior fabric properties at a higher production expense.

Environmental Impact and Sustainability Considerations

Polyester filament yarn typically exhibits lower environmental impact due to its production efficiency and recyclability, reducing resource consumption and waste generation. Draw textured yarn requires additional processing, leading to higher energy use and greater carbon emissions, which can challenge sustainability goals. Advancements in recycling technologies for both yarn types contribute to circular economies by minimizing landfill waste and promoting resource recovery.

Choosing the Right Yarn: Factors for Selecting PFY or DTY

Choosing between Polyester Filament Yarn (PFY) and Draw Textured Yarn (DTY) depends on the desired fabric characteristics and end-use applications. PFY offers smooth, lustrous fibers ideal for lightweight, sheer textiles, while DTY provides bulkier, stretchable yarns suitable for activewear and upholstery requiring elasticity and comfort. Consider factors such as durability, texture, moisture-wicking properties, and production cost to select the most efficient yarn type for specific textile manufacturing needs.

Polyester filament yarn vs Draw textured yarn Infographic

materialdif.com

materialdif.com