Solution-dyed polyester offers vibrant, long-lasting colors by adding pigments directly to the polymer before fiber extrusion, resulting in superior colorfastness and resistance to fading. Piece-dyed polyester undergoes dyeing after fabric production, allowing for a wider color range but lower durability and increased environmental impact due to water and chemical usage. Choosing solution-dyed polyester enhances sustainability and performance, especially for outdoor and high-use applications.

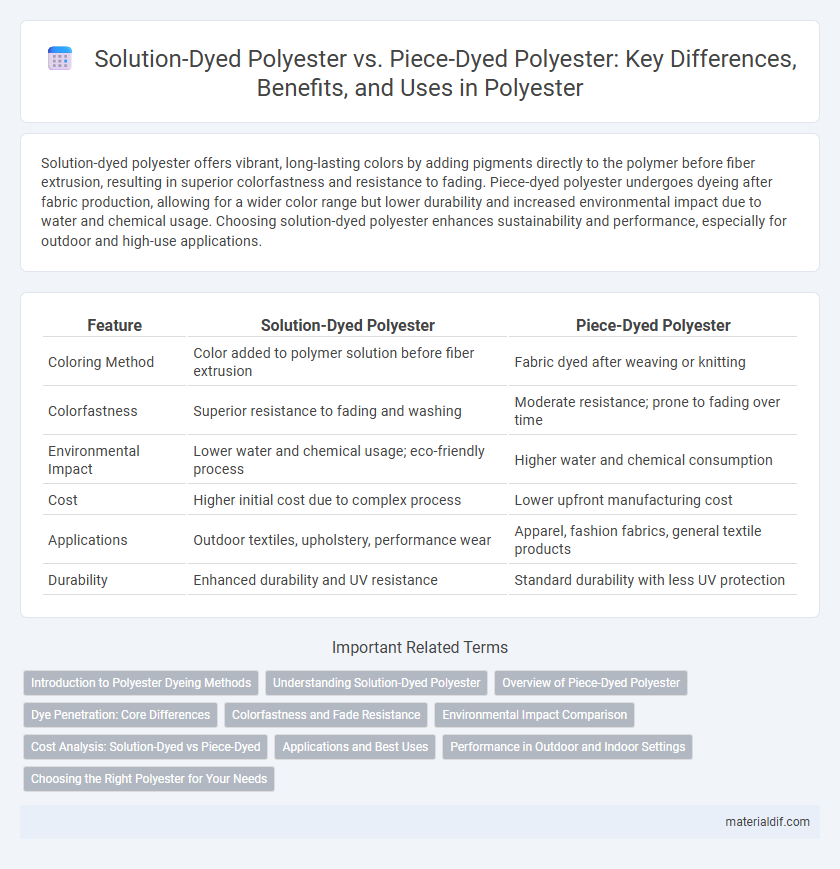

Table of Comparison

| Feature | Solution-Dyed Polyester | Piece-Dyed Polyester |

|---|---|---|

| Coloring Method | Color added to polymer solution before fiber extrusion | Fabric dyed after weaving or knitting |

| Colorfastness | Superior resistance to fading and washing | Moderate resistance; prone to fading over time |

| Environmental Impact | Lower water and chemical usage; eco-friendly process | Higher water and chemical consumption |

| Cost | Higher initial cost due to complex process | Lower upfront manufacturing cost |

| Applications | Outdoor textiles, upholstery, performance wear | Apparel, fashion fabrics, general textile products |

| Durability | Enhanced durability and UV resistance | Standard durability with less UV protection |

Introduction to Polyester Dyeing Methods

Solution-dyed polyester involves adding color pigments directly into the polymer solution before fiber extrusion, ensuring deep, long-lasting colorfastness and resistance to fading. Piece-dyed polyester, on the other hand, is dyed after the fabric is woven, allowing for greater color variety but often resulting in lower durability and color retention. These dyeing methods significantly impact the environmental footprint, with solution dyeing requiring less water and energy compared to traditional piece dyeing processes.

Understanding Solution-Dyed Polyester

Solution-dyed polyester undergoes pigment integration during the fiber extrusion process, resulting in superior colorfastness and resistance to fading compared to piece-dyed polyester. This method enhances UV resistance and reduces water and chemical usage, making it more sustainable and durable for outdoor applications. The fibers achieve consistent color throughout, minimizing color loss from wear and tear over time.

Overview of Piece-Dyed Polyester

Piece-dyed polyester involves dyeing the fabric after it has been woven, allowing for a wider range of vibrant colors and consistent color throughout the material. This method enhances fabric softness and drape while providing more flexibility in design and color matching for fashion and home textiles. The process is less colorfast compared to solution-dyed polyester, making it more susceptible to fading from prolonged exposure to sunlight or washing.

Dye Penetration: Core Differences

Solution-dyed polyester exhibits superior dye penetration as color pigments are added directly to the polymer solution before fiber formation, ensuring consistent and uniform coloration throughout the fiber's core. Piece-dyed polyester, however, undergoes dyeing after fabric production, typically resulting in color primarily on the fiber surface with limited penetration to the core. This core dyeing in solution-dyed polyester enhances colorfastness, durability, and resistance to fading compared to piece-dyed alternatives.

Colorfastness and Fade Resistance

Solution-dyed polyester offers superior colorfastness and fade resistance compared to piece-dyed polyester due to the color being integrated into the fiber during polymer extrusion. This process ensures that the color penetrates the entire fiber, resulting in enhanced durability against UV exposure, washing, and abrasion. Piece-dyed polyester, with color applied after fiber formation, typically shows quicker fading and reduced resistance to environmental factors.

Environmental Impact Comparison

Solution-dyed polyester significantly reduces water consumption and chemical usage by integrating color pigments during fiber production, leading to lower environmental pollution compared to piece-dyed polyester, which requires substantial water and dye chemicals in post-production. The energy efficiency of solution-dyed polyester also surpasses piece-dyed methods by eliminating multiple dyeing and drying cycles. Consequently, solution-dyed polyester demonstrates a smaller carbon footprint and less wastewater generation, making it a more sustainable textile option.

Cost Analysis: Solution-Dyed vs Piece-Dyed

Solution-dyed polyester typically incurs higher initial costs due to the integration of color pigments during fiber extrusion, leading to long-term savings with lower energy consumption and reduced water usage during production. Piece-dyed polyester requires dyeing after fabric formation, increasing operational expenses linked to water, chemicals, and wastewater treatment, often resulting in higher environmental and processing costs. When evaluating cost efficiency, solution dyeing proves more economical in large-scale production despite upfront investment, driven by durability and resource savings.

Applications and Best Uses

Solution-dyed polyester offers superior colorfastness and UV resistance, making it ideal for outdoor applications such as awnings, marine fabrics, and sportswear exposed to harsh sunlight. Piece-dyed polyester provides more versatile color options and is commonly used in fashion apparel, upholstery, and indoor furnishings where vibrant hues and customizable shades are essential. Selecting solution-dyed polyester enhances durability and fade resistance in environments with intense exposure, while piece-dyed polyester delivers flexibility and a wide color range for everyday textile uses.

Performance in Outdoor and Indoor Settings

Solution-dyed polyester offers superior colorfastness and UV resistance, making it ideal for outdoor applications where prolonged exposure to sunlight and harsh weather conditions occur. Piece-dyed polyester, while more versatile in design options, tends to fade faster and absorb moisture, reducing its durability in outdoor environments but performing adequately indoors with less intense light exposure. The inherent color integrity of solution-dyed fibers ensures extended lifespan and sustained aesthetic appeal in both outdoor and demanding indoor settings.

Choosing the Right Polyester for Your Needs

Solution-dyed polyester offers superior colorfastness and resistance to fading due to pigment incorporation during fiber extrusion, making it ideal for outdoor and high-exposure applications. Piece-dyed polyester provides more color variety and design flexibility as dyeing occurs after fabric production, suitable for fashion and indoor textiles. Selecting between the two depends on the balance of durability, color retention, and application-specific requirements.

Solution-dyed polyester vs Piece-dyed polyester Infographic

materialdif.com

materialdif.com