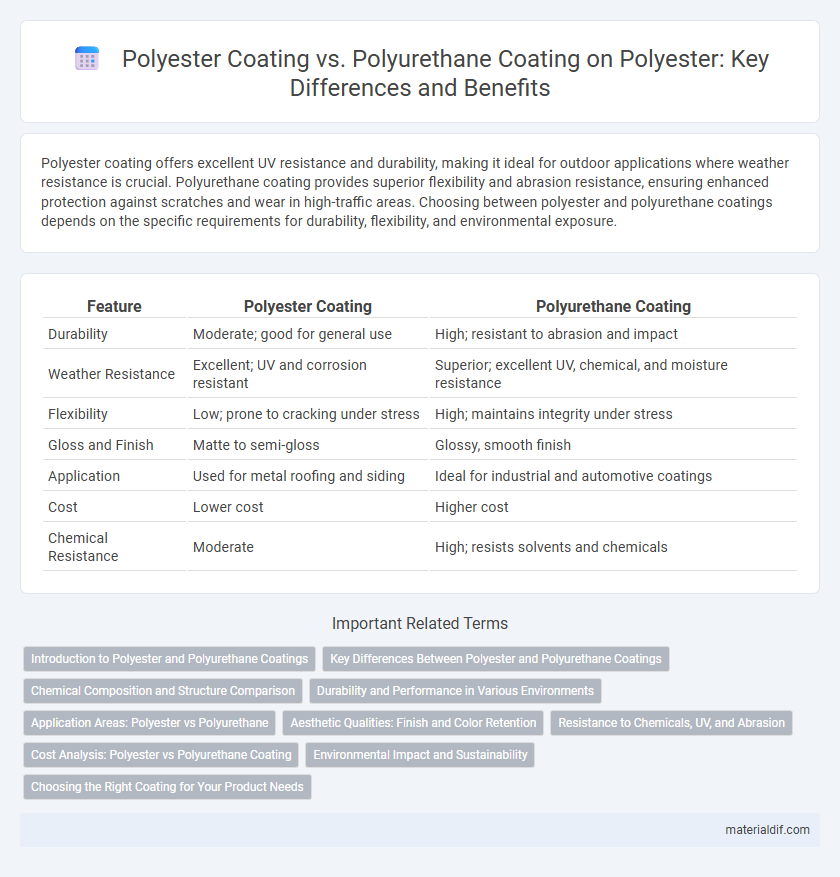

Polyester coating offers excellent UV resistance and durability, making it ideal for outdoor applications where weather resistance is crucial. Polyurethane coating provides superior flexibility and abrasion resistance, ensuring enhanced protection against scratches and wear in high-traffic areas. Choosing between polyester and polyurethane coatings depends on the specific requirements for durability, flexibility, and environmental exposure.

Table of Comparison

| Feature | Polyester Coating | Polyurethane Coating |

|---|---|---|

| Durability | Moderate; good for general use | High; resistant to abrasion and impact |

| Weather Resistance | Excellent; UV and corrosion resistant | Superior; excellent UV, chemical, and moisture resistance |

| Flexibility | Low; prone to cracking under stress | High; maintains integrity under stress |

| Gloss and Finish | Matte to semi-gloss | Glossy, smooth finish |

| Application | Used for metal roofing and siding | Ideal for industrial and automotive coatings |

| Cost | Lower cost | Higher cost |

| Chemical Resistance | Moderate | High; resists solvents and chemicals |

Introduction to Polyester and Polyurethane Coatings

Polyester coatings are widely recognized for their excellent weather resistance, durability, and cost-effectiveness, making them ideal for automotive and industrial applications. Polyurethane coatings, by contrast, offer superior chemical resistance, flexibility, and abrasion resistance, often used in environments requiring enhanced protection and aesthetic finish. Both coatings serve critical roles in surface protection, with polyester excelling in outdoor exposure scenarios and polyurethane preferred for high-performance, durable finishes.

Key Differences Between Polyester and Polyurethane Coatings

Polyester coatings are known for their excellent durability, UV resistance, and cost-effectiveness, making them ideal for outdoor applications where weather resistance is crucial. Polyurethane coatings offer superior flexibility, abrasion resistance, and chemical resistance, which makes them suitable for surfaces exposed to mechanical wear or harsh chemicals. The key differences lie in polyester coatings excelling in stiffness and environmental resistance, while polyurethane coatings provide enhanced elasticity and surface protection.

Chemical Composition and Structure Comparison

Polyester coatings consist primarily of saturated or unsaturated polyester resins formed through the polycondensation of diols and dicarboxylic acids, resulting in a carbonyl-rich backbone that provides moderate chemical resistance and flexibility. In contrast, polyurethane coatings are composed of urethane linkages formed by the reaction of polyols with isocyanates, creating a segmented polymer structure with hard and soft segments that offer superior abrasion resistance and elasticity. The chemical composition difference leads to polyester coatings having faster curing times and UV stability, whereas polyurethane coatings exhibit enhanced chemical resistance and mechanical durability due to their nitrogen-containing urethane bonds.

Durability and Performance in Various Environments

Polyester coating offers excellent UV resistance and weatherproofing, making it highly durable for outdoor applications, especially in harsh sunlight and moisture exposure. Polyurethane coating provides superior chemical resistance and flexibility, performing well in environments with frequent abrasion or impact. Both coatings are effective, but polyester excels in maintaining color and gloss over time, while polyurethane withstands mechanical wear and chemical exposure better.

Application Areas: Polyester vs Polyurethane

Polyester coatings are widely used in architectural panels, automotive parts, and packaging due to their excellent UV resistance, hardness, and gloss retention. Polyurethane coatings find extensive application in flooring, furniture, and industrial equipment where superior abrasion resistance, flexibility, and chemical resistance are critical. Both coatings serve distinct industrial needs, with polyester preferred for outdoor exposure and polyurethane favored for durable, high-performance surfaces.

Aesthetic Qualities: Finish and Color Retention

Polyester coatings offer a smooth finish with excellent color retention that resists fading under UV exposure, making them ideal for outdoor applications requiring long-lasting vibrancy. Polyurethane coatings provide a glossier and more elastic finish, enhancing surface depth and offering superior resistance to scratches and chemical abrasion. Both coatings maintain color well, but polyurethane excels in preserving gloss and aesthetic appeal over extended periods in harsh environments.

Resistance to Chemicals, UV, and Abrasion

Polyester coating offers excellent resistance to UV radiation and maintains color stability, while polyurethane coating provides superior chemical resistance and abrasion toughness. Polyester coatings are more prone to degradation under harsh chemical exposure, whereas polyurethane formulations withstand solvents, oils, and acids better. Abrasion resistance is significantly higher in polyurethane coatings, making them ideal for applications requiring durability against mechanical wear and chemical attack.

Cost Analysis: Polyester vs Polyurethane Coating

Polyester coatings typically offer a lower initial cost compared to polyurethane coatings, making them a cost-effective choice for budget-conscious projects. However, polyurethane coatings provide superior durability and chemical resistance, which can reduce maintenance expenses and extend the lifespan of coated surfaces. When analyzing long-term cost efficiency, polyurethane coatings often deliver better value despite their higher upfront price.

Environmental Impact and Sustainability

Polyester coatings typically have higher volatile organic compound (VOC) emissions compared to polyurethane coatings, contributing to greater environmental pollution during application and curing. Polyurethane coatings offer enhanced durability and chemical resistance, extending the lifespan of coated products and reducing the frequency of recoating, which supports sustainability through resource conservation. Both coatings are increasingly being formulated with bio-based and low-VOC components to minimize ecological footprints and comply with stricter environmental regulations.

Choosing the Right Coating for Your Product Needs

Polyester coating offers excellent UV resistance and weatherability, making it ideal for outdoor applications where durability and color retention are critical. Polyurethane coating provides superior abrasion resistance and flexibility, suited for products exposed to heavy wear or impact. Selecting the right coating depends on balancing environmental exposure, mechanical stress, and desired finish longevity to optimize performance and cost-efficiency.

Polyester Coating vs Polyurethane Coating Infographic

materialdif.com

materialdif.com