Textured polyester yarn offers enhanced elasticity, softness, and breathability compared to flat polyester yarn, making it ideal for activewear and comfortable garments. The crimped fibers in textured yarn create air pockets that improve moisture-wicking and insulation properties. Flat polyester yarn, while smoother and more lustrous, tends to be less flexible and breathable, often used in applications requiring a sleek, durable finish.

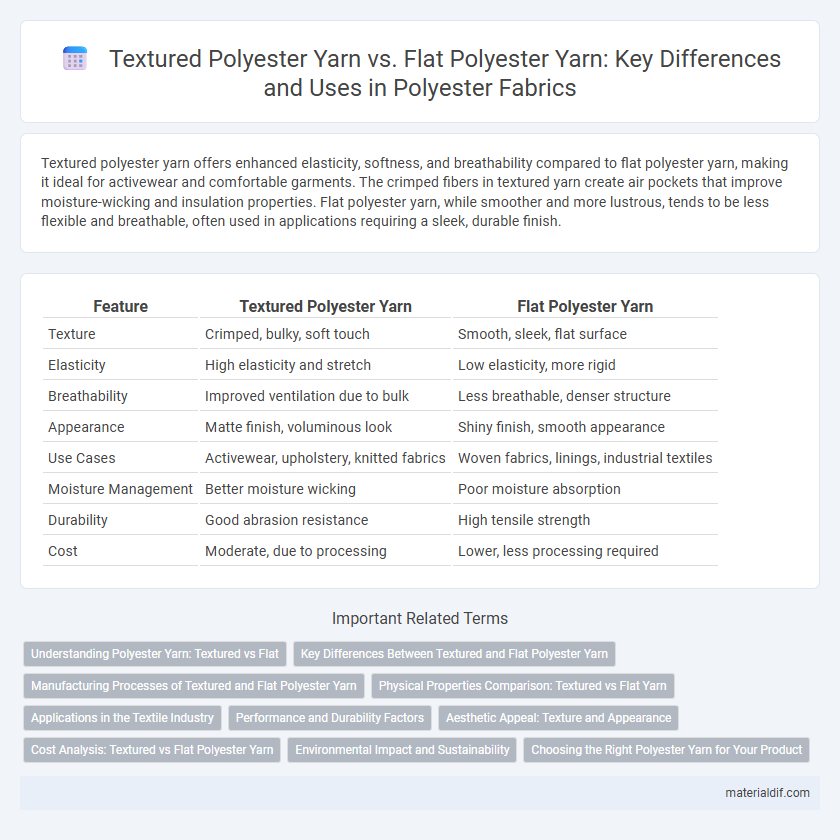

Table of Comparison

| Feature | Textured Polyester Yarn | Flat Polyester Yarn |

|---|---|---|

| Texture | Crimped, bulky, soft touch | Smooth, sleek, flat surface |

| Elasticity | High elasticity and stretch | Low elasticity, more rigid |

| Breathability | Improved ventilation due to bulk | Less breathable, denser structure |

| Appearance | Matte finish, voluminous look | Shiny finish, smooth appearance |

| Use Cases | Activewear, upholstery, knitted fabrics | Woven fabrics, linings, industrial textiles |

| Moisture Management | Better moisture wicking | Poor moisture absorption |

| Durability | Good abrasion resistance | High tensile strength |

| Cost | Moderate, due to processing | Lower, less processing required |

Understanding Polyester Yarn: Textured vs Flat

Textured polyester yarn features a bulkier, crimped structure that enhances elasticity, moisture-wicking, and thermal insulation, making it ideal for activewear and upholstery. Flat polyester yarn, characterized by its smooth, sleek surface, offers higher strength and a glossy finish favored in formal garments and linings. Understanding these distinctions helps manufacturers choose the appropriate yarn type based on fabric performance requirements and end-use applications.

Key Differences Between Textured and Flat Polyester Yarn

Textured polyester yarn features a crimped or twisted structure that enhances elasticity, breathability, and moisture-wicking properties, making it ideal for activewear and stretchable fabrics. Flat polyester yarn, with its smooth and uniform surface, offers higher tensile strength and durability, commonly used in upholstery and industrial applications where firmness is essential. The key differences lie in texture, flexibility, moisture management, and application suitability, with textured yarn excelling in comfort and flat yarn in resilience.

Manufacturing Processes of Textured and Flat Polyester Yarn

Textured polyester yarn is produced through a process called false-twist texturizing, where the flat filament yarn is twisted, heat-set, and untwisted to create bulk and stretchability. Flat polyester yarn, also known as flat filament yarn, undergoes minimal finishing; it is directly drawn and wound without additional texturizing steps, resulting in a smooth and lustrous surface. The key difference lies in the thermal-mechanical treatment applied to textured yarn to impart volume and elasticity, whereas flat yarn maintains a flat, sleek profile due to the absence of such processing.

Physical Properties Comparison: Textured vs Flat Yarn

Textured polyester yarn exhibits increased bulkiness, elasticity, and softness compared to flat polyester yarn, resulting from its crimped and spun structure that enhances air retention and moisture-wicking properties. Flat polyester yarn, characterized by its smooth and compact form, provides higher tensile strength and better durability but lacks the stretch and resilience of textured yarn. The physical properties of textured yarn make it ideal for applications requiring comfort and flexibility, whereas flat yarn suits products demanding rigidity and resistance to abrasion.

Applications in the Textile Industry

Textured polyester yarn, known for its bulkiness and elasticity, is widely used in sportswear, upholstery, and home textiles due to its enhanced comfort and breathability. Flat polyester yarn, characterized by its smooth surface and strength, finds applications in industrial fabrics, sewing threads, and linings where durability and resistance to abrasion are essential. Both yarn types are integral in textile manufacturing, with textured yarns prioritized for aesthetics and performance, while flat yarns meet demands for structural integrity and wear resistance.

Performance and Durability Factors

Textured polyester yarn offers enhanced elasticity and breathability compared to flat polyester yarn, making it ideal for activewear and sports textiles. Flat polyester yarn provides superior smoothness and strength, ensuring high durability and resistance to abrasion in heavy-duty applications. Performance-wise, textured yarn improves comfort and moisture management, whereas flat yarn excels in structural integrity and long-lasting wear.

Aesthetic Appeal: Texture and Appearance

Textured polyester yarn enhances fabric aesthetics through its voluminous, crimped surface that adds depth and a soft, natural appearance, making garments look more dynamic and luxurious. Flat polyester yarn offers a smooth, sleek finish with consistent sheen, ideal for streamlined, polished looks in apparel. The choice influences textile design by balancing tactile interest and visual sophistication, catering to diverse fashion and interior applications.

Cost Analysis: Textured vs Flat Polyester Yarn

Textured polyester yarn typically incurs higher production costs due to the additional processes like texturizing and air-jet treatment, which enhance yarn bulk and elasticity. Flat polyester yarn, being simpler to manufacture, usually offers a more cost-effective option for applications prioritizing affordability over texture. Businesses balancing quality and budget often analyze these cost differences to choose yarn type based on product performance requirements and pricing strategy.

Environmental Impact and Sustainability

Textured polyester yarn consumes more energy and water during manufacturing compared to flat polyester yarn, resulting in a higher carbon footprint. Flat polyester yarn production typically generates less waste and requires fewer chemical treatments, enhancing its overall sustainability profile. Choosing flat polyester yarn can contribute to reduced environmental impact due to its more efficient resource utilization and lower emissions.

Choosing the Right Polyester Yarn for Your Product

Textured polyester yarn offers enhanced stretch, softness, and breathability, making it ideal for activewear and comfortable apparel, whereas flat polyester yarn provides a smooth, lustrous finish suitable for formal wear and upholstery. Selecting the right polyester yarn depends on the desired fabric properties such as drape, texture, and durability, with textured yarns improving moisture management and flat yarns ensuring a sleek appearance. Understanding the end-use of the product and performance requirements guides the choice between textured and flat polyester yarn for optimal fabric functionality.

Textured Polyester Yarn vs Flat Polyester Yarn Infographic

materialdif.com

materialdif.com