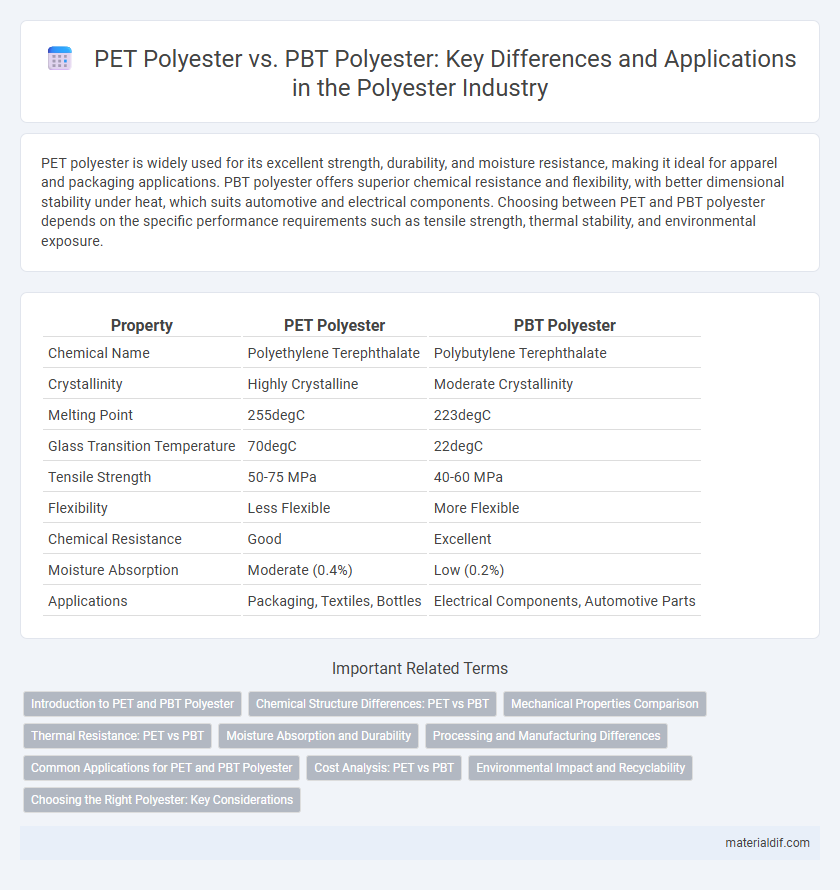

PET polyester is widely used for its excellent strength, durability, and moisture resistance, making it ideal for apparel and packaging applications. PBT polyester offers superior chemical resistance and flexibility, with better dimensional stability under heat, which suits automotive and electrical components. Choosing between PET and PBT polyester depends on the specific performance requirements such as tensile strength, thermal stability, and environmental exposure.

Table of Comparison

| Property | PET Polyester | PBT Polyester |

|---|---|---|

| Chemical Name | Polyethylene Terephthalate | Polybutylene Terephthalate |

| Crystallinity | Highly Crystalline | Moderate Crystallinity |

| Melting Point | 255degC | 223degC |

| Glass Transition Temperature | 70degC | 22degC |

| Tensile Strength | 50-75 MPa | 40-60 MPa |

| Flexibility | Less Flexible | More Flexible |

| Chemical Resistance | Good | Excellent |

| Moisture Absorption | Moderate (0.4%) | Low (0.2%) |

| Applications | Packaging, Textiles, Bottles | Electrical Components, Automotive Parts |

Introduction to PET and PBT Polyester

PET polyester, or polyethylene terephthalate, is a versatile thermoplastic polymer widely used in fibers, packaging, and engineering resins due to its excellent strength, chemical resistance, and thermal stability. PBT polyester, or polybutylene terephthalate, shares similar chemical properties but offers superior impact resistance, faster crystallization rates, and better dimensional stability for engineering applications. Both PET and PBT are part of the polyester family, with PET commonly used in textile fibers and beverage containers, while PBT is favored in automotive parts, electrical components, and industrial applications.

Chemical Structure Differences: PET vs PBT

PET polyester, chemically known as polyethylene terephthalate, consists of repeating units derived from terephthalic acid and ethylene glycol, forming a linear, semi-crystalline polymer. PBT polyester, or polybutylene terephthalate, differs by using butylene glycol instead of ethylene glycol, resulting in a more flexible and lower melting polymer chain. The structural variance between PET's two-carbon ethylene units and PBT's four-carbon butylene units influences thermal properties, crystallinity, and mechanical performance in textile and engineering applications.

Mechanical Properties Comparison

PET polyester exhibits higher tensile strength and greater modulus compared to PBT polyester, making it ideal for applications requiring rigidity and dimensional stability. PBT polyester offers superior impact resistance and better elongation at break, enhancing its toughness and flexibility under stress. These mechanical differences influence material selection in industries such as automotive and electronics, where specific performance characteristics are critical.

Thermal Resistance: PET vs PBT

PET polyester exhibits higher thermal resistance with a melting point around 260degC, making it suitable for applications requiring durability under elevated temperatures. In contrast, PBT polyester has a lower melting point near 223degC, offering faster crystallization and better dimensional stability but reduced heat tolerance compared to PET. This thermal property difference influences their respective uses in automotive parts, electrical components, and textiles where temperature performance is critical.

Moisture Absorption and Durability

PET polyester exhibits higher moisture absorption compared to PBT polyester, making it more susceptible to dimensional changes in humid conditions. PBT polyester offers superior durability and better resistance to hydrolysis, allowing it to maintain mechanical properties even with prolonged exposure to moisture. The low moisture uptake in PBT enhances its suitability for applications requiring high stability and longevity in damp environments.

Processing and Manufacturing Differences

PET polyester, derived from terephthalic acid and ethylene glycol, typically undergoes melt spinning and injection molding processes, offering high tensile strength and chemical resistance ideal for fibers and packaging films. PBT polyester, made from butanediol and terephthalic acid, exhibits faster crystallization rates during processing, enabling quicker cycle times in injection molding with improved dimensional stability and impact resistance. Manufacturing PBT requires precise temperature control to prevent degradation, while PET's higher melting point demands more energy-intensive processing conditions.

Common Applications for PET and PBT Polyester

PET polyester is widely used in packaging, textiles, and bottling due to its high strength, chemical resistance, and excellent dimensional stability. PBT polyester finds common applications in automotive parts, electrical components, and industrial machinery where superior impact resistance, thermal stability, and electrical insulation are crucial. Both materials serve critical roles in manufacturing but are selected based on specific performance requirements in consumer goods and industrial sectors.

Cost Analysis: PET vs PBT

PET polyester generally offers a lower cost per kilogram compared to PBT polyester, making it a more economical choice for large-scale textile and packaging applications. PBT polyester tends to have higher raw material and processing expenses due to its enhanced mechanical properties and chemical resistance, which can impact overall production costs. Manufacturers often weigh PET's affordability against PBT's performance benefits when conducting cost-benefit analyses for specific industrial uses.

Environmental Impact and Recyclability

PET polyester demonstrates superior recyclability compared to PBT polyester due to well-established global recycling infrastructure targeting polyethylene terephthalate materials. While both PET and PBT are thermoplastic polyesters, PET's widespread use in packaging and textiles results in higher recycling rates and reduced environmental impact through efficient closed-loop systems. PBT polyester, although offering excellent chemical resistance and mechanical properties, faces limited recycling options and contributes more significantly to landfill accumulation and post-consumer waste challenges.

Choosing the Right Polyester: Key Considerations

Choosing the right polyester depends on application-specific requirements such as chemical resistance, thermal stability, and mechanical strength. PET polyester offers excellent tensile strength and is widely used in textiles and packaging due to its clarity and recyclability, while PBT polyester provides superior chemical resistance and dimensional stability, making it ideal for automotive and electrical components. Evaluating factors like moisture absorption, processing temperature, and end-use environment ensures optimal performance and durability between PET and PBT polyesters.

PET Polyester vs PBT Polyester Infographic

materialdif.com

materialdif.com