Polyester staple fiber consists of short fibers spun together to create a fabric with a soft texture and natural feel, making it ideal for applications like apparel and home textiles. In contrast, polyester filament yarn is made of continuous long fibers that provide higher strength, durability, and a smooth, shiny surface, commonly used in industrial textiles and high-performance fabrics. Choosing between the two depends on the desired fabric characteristics, with staple fibers offering comfort and filament yarns delivering resilience and sheen.

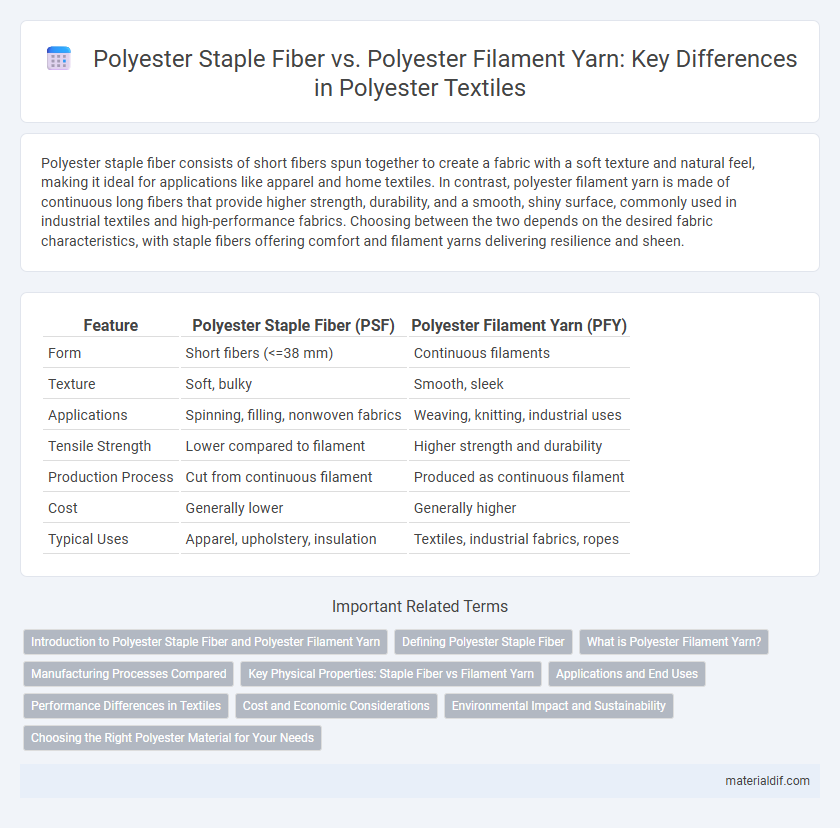

Table of Comparison

| Feature | Polyester Staple Fiber (PSF) | Polyester Filament Yarn (PFY) |

|---|---|---|

| Form | Short fibers (<=38 mm) | Continuous filaments |

| Texture | Soft, bulky | Smooth, sleek |

| Applications | Spinning, filling, nonwoven fabrics | Weaving, knitting, industrial uses |

| Tensile Strength | Lower compared to filament | Higher strength and durability |

| Production Process | Cut from continuous filament | Produced as continuous filament |

| Cost | Generally lower | Generally higher |

| Typical Uses | Apparel, upholstery, insulation | Textiles, industrial fabrics, ropes |

Introduction to Polyester Staple Fiber and Polyester Filament Yarn

Polyester Staple Fiber (PSF) consists of short, cut fibers typically ranging from 38mm to 51mm, used predominantly in textile applications such as spun yarns, nonwovens, and home furnishings. Polyester Filament Yarn (PFY) features continuous, long fibers that provide high tensile strength and smooth texture, making it ideal for weaving, knitting, and industrial uses. Both PSF and PFY are derived from polyethylene terephthalate (PET), but PSF offers versatility in blending with natural fibers while PFY delivers superior durability and luster.

Defining Polyester Staple Fiber

Polyester Staple Fiber consists of short, cut fibers typically 38-64 mm in length, used in spinning to create yarns with a wool-like texture, enhancing fabric softness and insulation. Unlike continuous Polyester Filament Yarn, staple fibers offer better breathability and are ideal for blending with natural fibers such as cotton or wool. This fiber type plays a crucial role in producing nonwoven fabrics, upholstery, and apparel requiring durability and comfort.

What is Polyester Filament Yarn?

Polyester filament yarn consists of continuous, long fibers made from synthetic polyester polymers, providing high strength, durability, and smooth texture suitable for weaving and knitting. Unlike polyester staple fiber, which is cut into short lengths, filament yarn maintains fiber length integrity, resulting in better tensile properties and less pilling in finished fabrics. Common applications of polyester filament yarn include high-performance textiles, industrial fabrics, and seamless garments where uniformity and strength are critical.

Manufacturing Processes Compared

Polyester Staple Fiber manufacturing involves cutting continuous filaments into short lengths before spinning them into yarn, whereas Polyester Filament Yarn production retains the fiber as continuous filaments, which are then twisted directly into yarn. Staple fiber production includes carding, drawing, and spinning processes similar to natural fibers, creating yarns with a textured and bulky feel, while filament yarn manufacturing emphasizes filament extrusion, cooling, and winding steps, resulting in smooth, strong, and lustrous yarns. The difference in manufacturing processes affects the end-use properties, with staple fibers offering warmth and softness, and filament yarns providing high tensile strength and durability.

Key Physical Properties: Staple Fiber vs Filament Yarn

Polyester staple fiber consists of short, discrete fibers typically 38-51 mm in length, providing a soft texture and excellent insulation due to numerous fiber ends. Polyester filament yarn features continuous, long filaments that offer high tensile strength, smoothness, and durability, making it ideal for weaving and knitting applications requiring resilience. Staple fiber's crimped structure enhances bulk and elasticity, while filament yarn's uniform surface minimizes pilling and improves abrasion resistance.

Applications and End Uses

Polyester Staple Fiber is widely used in textile applications such as upholstery, carpets, and nonwoven fabrics due to its short fiber length, which offers enhanced versatility and blending capability with natural fibers like cotton. Polyester Filament Yarn, characterized by continuous filament strands, is primarily utilized in high-strength applications such as industrial sewing threads, sportswear, and automotive airbags, providing superior durability and tensile strength. The selection between Staple Fiber and Filament Yarn depends on the end-use requirements, where Staple Fiber excels in softness and comfort, while Filament Yarn is preferred for performance and structural integrity.

Performance Differences in Textiles

Polyester staple fiber offers greater softness and warmth, making it ideal for blended fabrics and casual wear, while polyester filament yarn provides superior strength, smoothness, and durability, suited for high-performance textiles and technical applications. Staple fibers result in fabrics with a more natural feel due to their shorter length and fuzzy texture, enhancing moisture absorption and breathability. Filament yarn's continuous filament structure yields less pilling and better sheen, increased tensile strength, and enhanced abrasion resistance, optimizing them for upholstery, industrial fabric, and sportswear.

Cost and Economic Considerations

Polyester Staple Fiber generally costs less to produce than Polyester Filament Yarn due to lower raw material quality and simpler manufacturing processes. Staple fiber's shorter fiber length leads to higher yarn hairiness, increasing downstream processing costs, while filament yarn's continuous fibers offer better strength and durability, justifying its higher price. Economically, staple fibers are preferred for affordable, bulk textile production, whereas filament yarns are favored in high-performance, premium applications.

Environmental Impact and Sustainability

Polyester staple fiber and polyester filament yarn differ in environmental impact and sustainability due to their production processes and end-of-life options. Polyester staple fiber, made from shorter fibers, often uses recycled PET bottles, reducing plastic waste and lowering carbon emissions compared to virgin polyester filament yarn, which requires more energy-intensive manufacturing. Both materials pose challenges in biodegradability, but recycled polyester staple fiber supports circular economy initiatives, promoting resource efficiency and waste reduction.

Choosing the Right Polyester Material for Your Needs

Polyester Staple Fiber consists of short fibers ideal for spun yarns, providing softness and breathability suited for casual wear and home textiles, while Polyester Filament Yarn offers continuous long fibers that ensure strength, durability, and smooth texture, making it perfect for industrial applications and high-performance fabrics. Selecting the right polyester material depends on the desired fabric characteristics, such as comfort, strength, and appearance, with staple fibers favored for versatility and filament yarns preferred for resilient, glossy finishes. Understanding these differences helps optimize material use for specific textile needs, enhancing product performance and consumer satisfaction.

Polyester Staple Fiber vs Polyester Filament Yarn Infographic

materialdif.com

materialdif.com